Refrigeration Service Operations

149

Solenoid Valves

NOTE: Valves that have nylon seats must be

disassembled before soldering.

Removal

1. Recover the refrigerant charge.

2. Remove the coil, and disassemble the valve if

necessary.

3. Unsolder the refrigeration lines from the

valve, and remove the valve from the unit.

Installation

1. Clean the tubes for soldering.

2. Remove the coil, disassemble the valve if

necessary, and place the valve in position.

3. Solder the inlet and outlet connections. After

the valve cools, assemble the valve and install

the coil.

4. Pressurize the refrigeration system and test for

leaks.

5. If no leaks are found, evacuate the system.

6. Recharge the unit with proper refrigerant and

check the compressor oil.

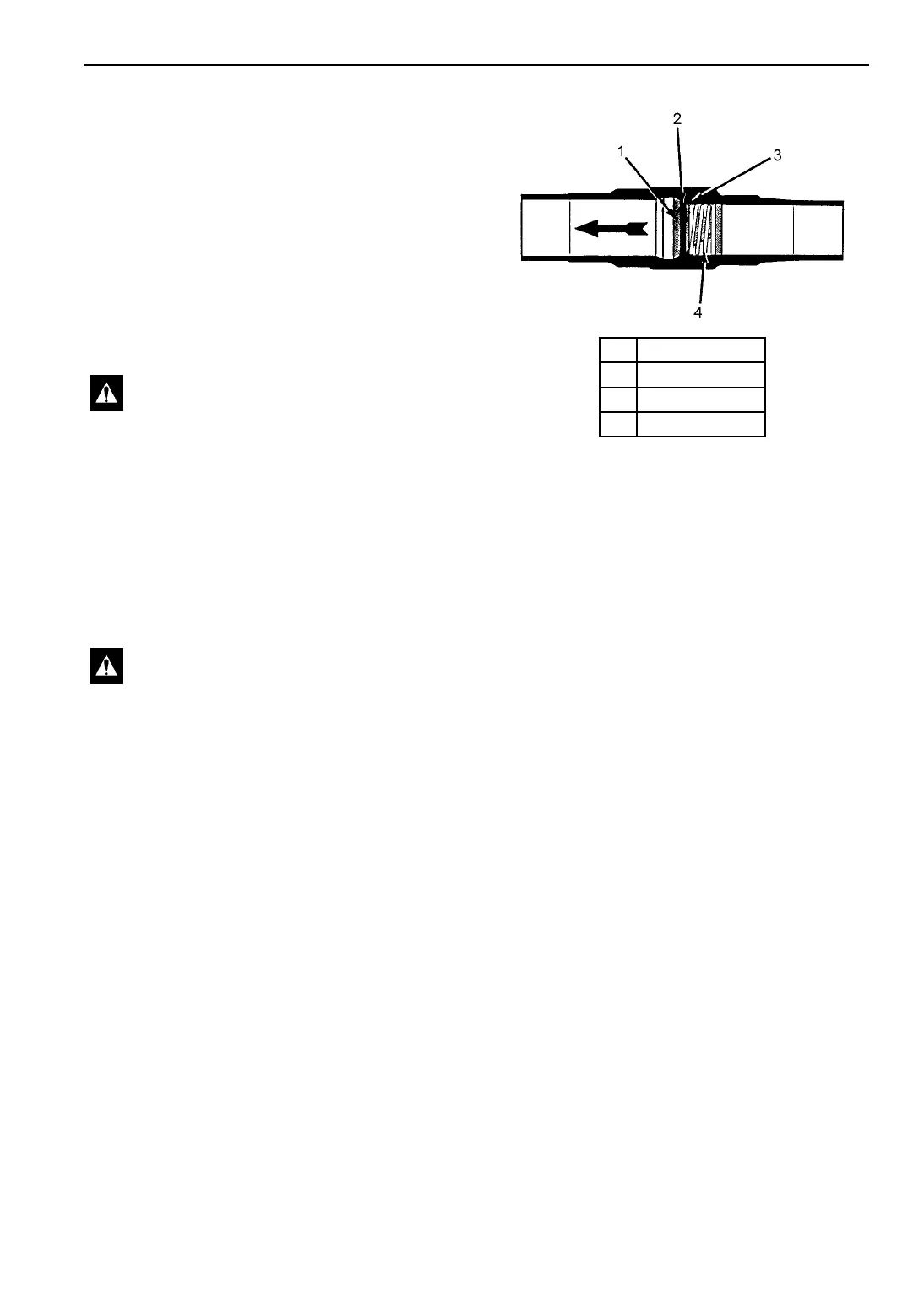

In-Line Check Valves

This unit uses some in-line check valves. An

in-line check valve is not repairable and must be

replaced if it fails. A heat sink must be used on the

in-line check valve when it is being soldered in

place to prevent damage to the neoprene seal.

Removal

1. Recover the refrigerant charge.

2. Place a heat sink on the check valve.

3. Unsolder the lines and remove the check

valve.

Installation

NOTE: A heat sink must be used on the in-line

check valve when it is being soldered in place to

prevent damage to the neoprene seal.

1. Clean the tubes for soldering.

2. Place the check valve in position. The arrow

on the valve body indicates the direction of

refrigerant flow through the valve.

3. Place a heat sink on the check valve.

4. Solder the inlet and outlet connections.

5. Pressurize the refrigeration system and test for

leaks.

6. If no leaks are found, evacuate the system.

7. Recharge the unit with proper refrigerant and

check the compressor oil.

CAUTION: Use a heat sink to prevent

damage.

CAUTION: Use a heat sink to prevent

damage.

1. Valve

2. Neoprene Seal

3. Valve Seat

4. Spring

Figure 173: Cross Section of In-line Check Valve

Loading...

Loading...