Refrigeration Maintenance

130

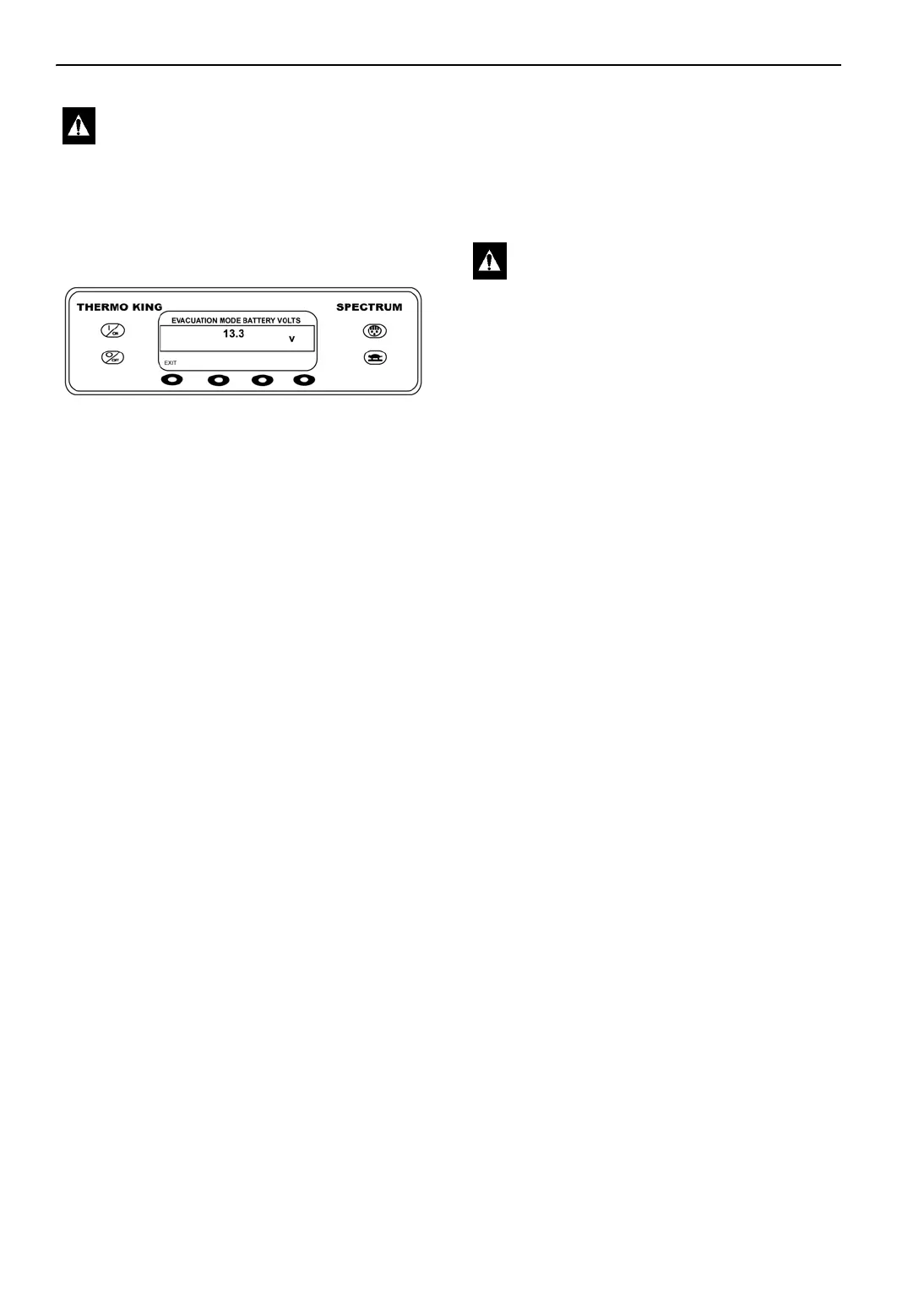

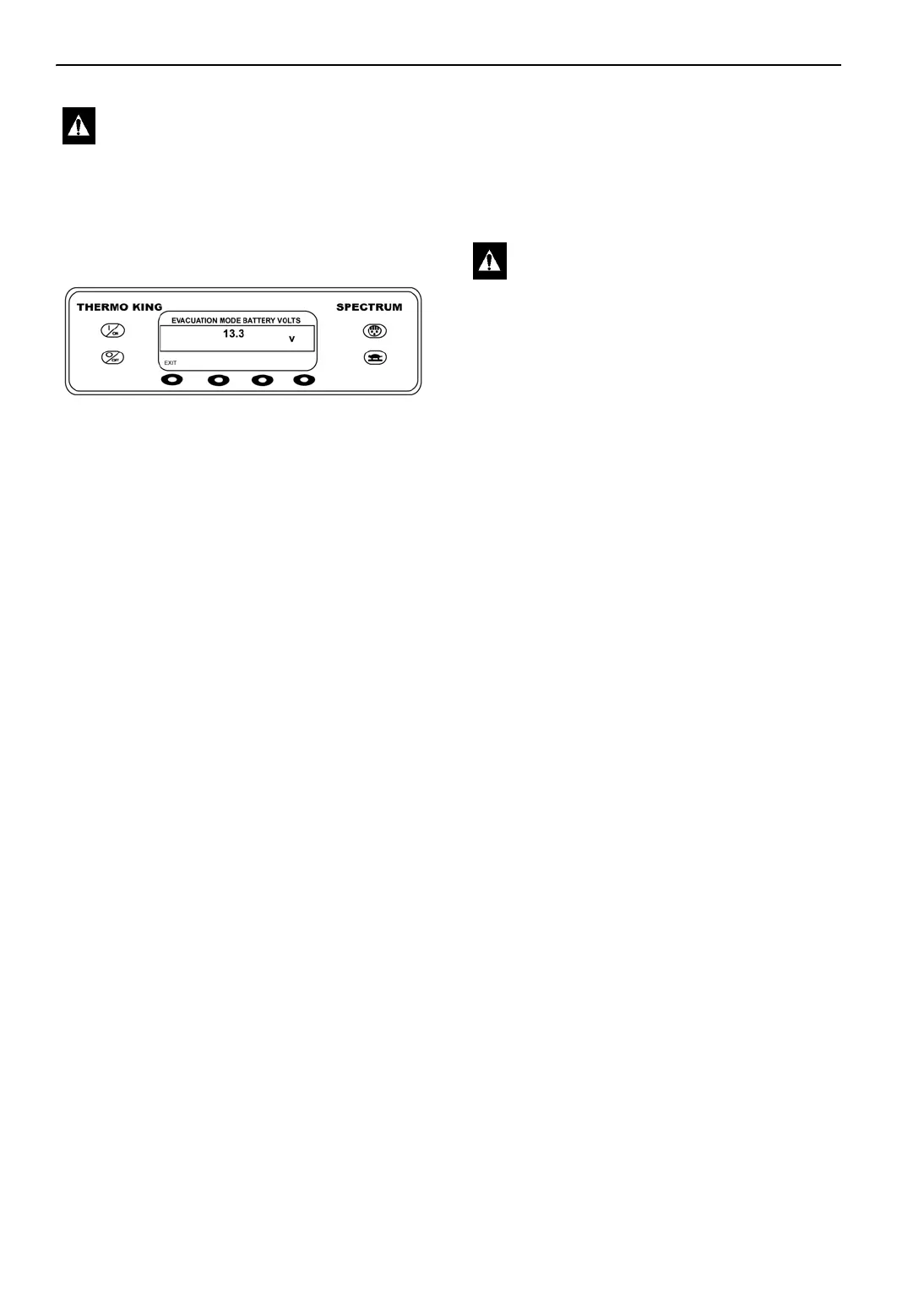

The battery voltage is shown and all normally

closed refrigeration valves are opened. They will

remain open until the EXIT key is pressed or the

battery voltage falls below a minimum voltage.

Figure 158: Battery voltage

Proceed with system leak check or evacuation.

Leak Check System

NOTE: Refer to Diagnosing Thermo King

Refrigeration Systems (TK-5984-10) for leak

detection procedures.

1. Put the unit into Evacuation Mode (see “Using

The Evacuation Mode Menu” on page 129).

2. Connect leak test gas (R-404a) supply to

center hose of gauge manifold.

3. Attach gauge manifold hoses to the suction

service valve and the discharge service port. A

low loss fitting must be used on the hose

connected to the discharge service port.

4. Pressurize the system with leak test gas. If

desired, system pressure may be boosted using

nitrogen gas.

5. Check connections made during installation

for leaks using electronic leak detector and/or

soap bubbles.

6. Recover test gas to repair leaks. System must

be vented while repairing solder joint leaks.

Pressurize system and check again after a leak

has been repaired.

7. If no leaks are found recover test gas to 0 psi.

Unit Evacuation

NOTE: Do not attempt to evacuate the unit until

the evacuation equipment has been tested and its

performance has been verified.

1. Prepare the unit for evacuation. Recover

refrigerant to 0 psig (0 kPa).

NOTE: New Federal Regulations may

require your recovery machine to pull the

system’s pressures lower than 0 psig [0 kPa].

2. Put the unit into Evacuation Mode (see “Using

The Evacuation Mode Menu” on page 129).

3. Install the evacuation station hoses on the

receiver tank outlet valve, suction service

valve, and discharge service port. A low loss

fitting must be used on the hose connected to

the discharge service port.

4. Mid-seat the receiver tank outlet valve and

suction service valve, and install the valve

stem caps.

5. Connect a gauge manifold and refrigerant

supply to the charging port above valve V-4.

Bottle valve closed.

6. Start the vacuum pump and open valves V-1,

V-2, V-3, V-4.

7. Evacuate the system to 500 microns or the

lowest achievable level between 500 and 1000

microns.

NOTE: The presence of refrigerant in the

compressor oil may prevent a low micron

reading from being achieved. The oil can

continue to “outgas” for long periods of

time. If the micron level appears to stall after

1/2 hour or 45 minutes between 1000 and

1500 microns, back seat the suction service

valve and observe the micron gauge. A sharp

drop in the micron reading (300 to 500

microns) would indicate that refrigerant is

present in the oil or a leak exists in the

compressor area. The micron gauge reads

“ATM” if there is a leak to the atmosphere.

See Figure 152 on page 128.

WARNING: Do not set battery charger to

the “crank” or “start” position, otherwise

the HMI display will be damaged.

CAUTION: Do not attempt to evacuate a

unit until you are certain that the unit is

leak free. A unit with less than a full

refrigerant charge should be thoroughly

leak checked and all leaks must be

repaired.

Loading...

Loading...