Engine Maintenance

118

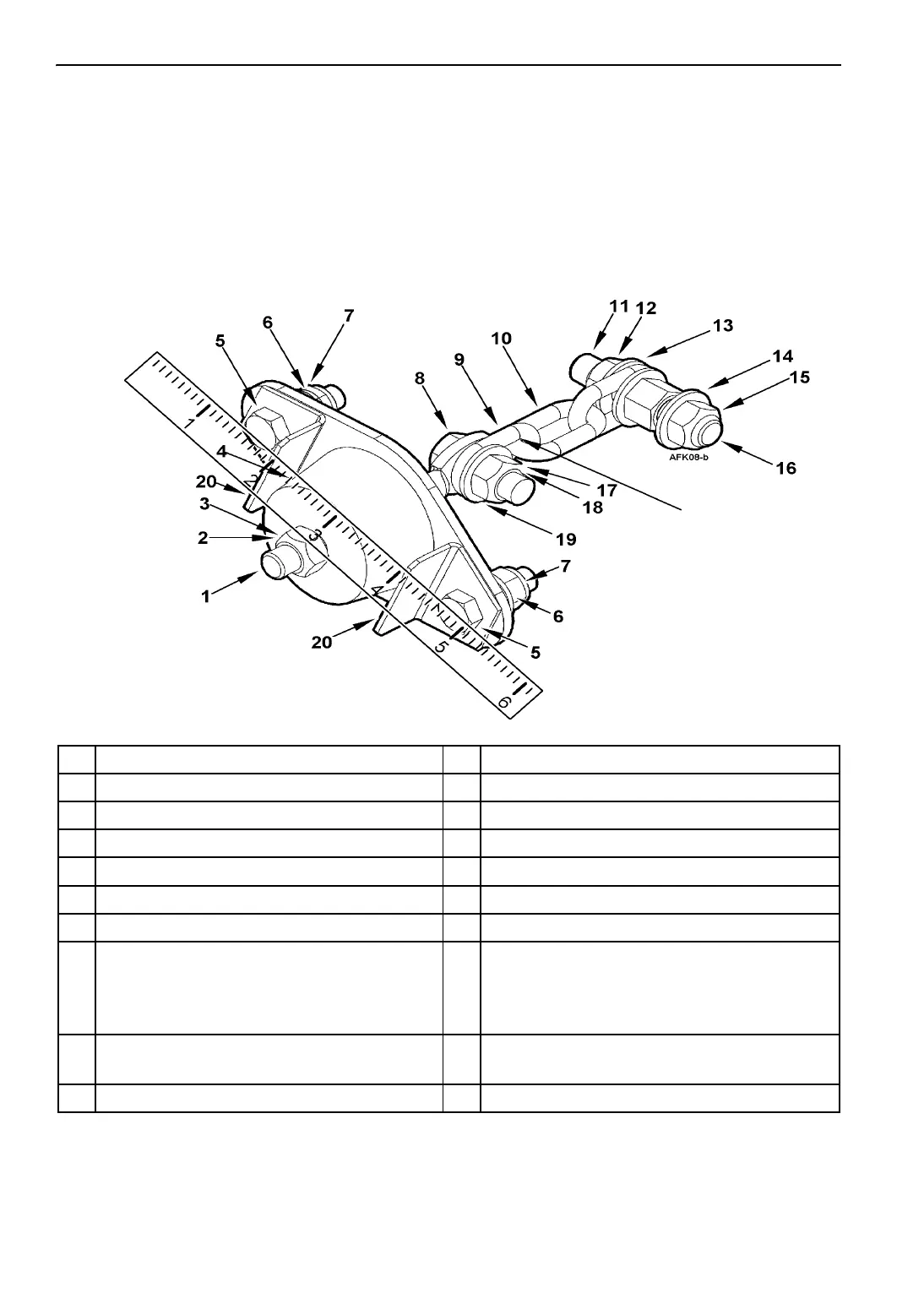

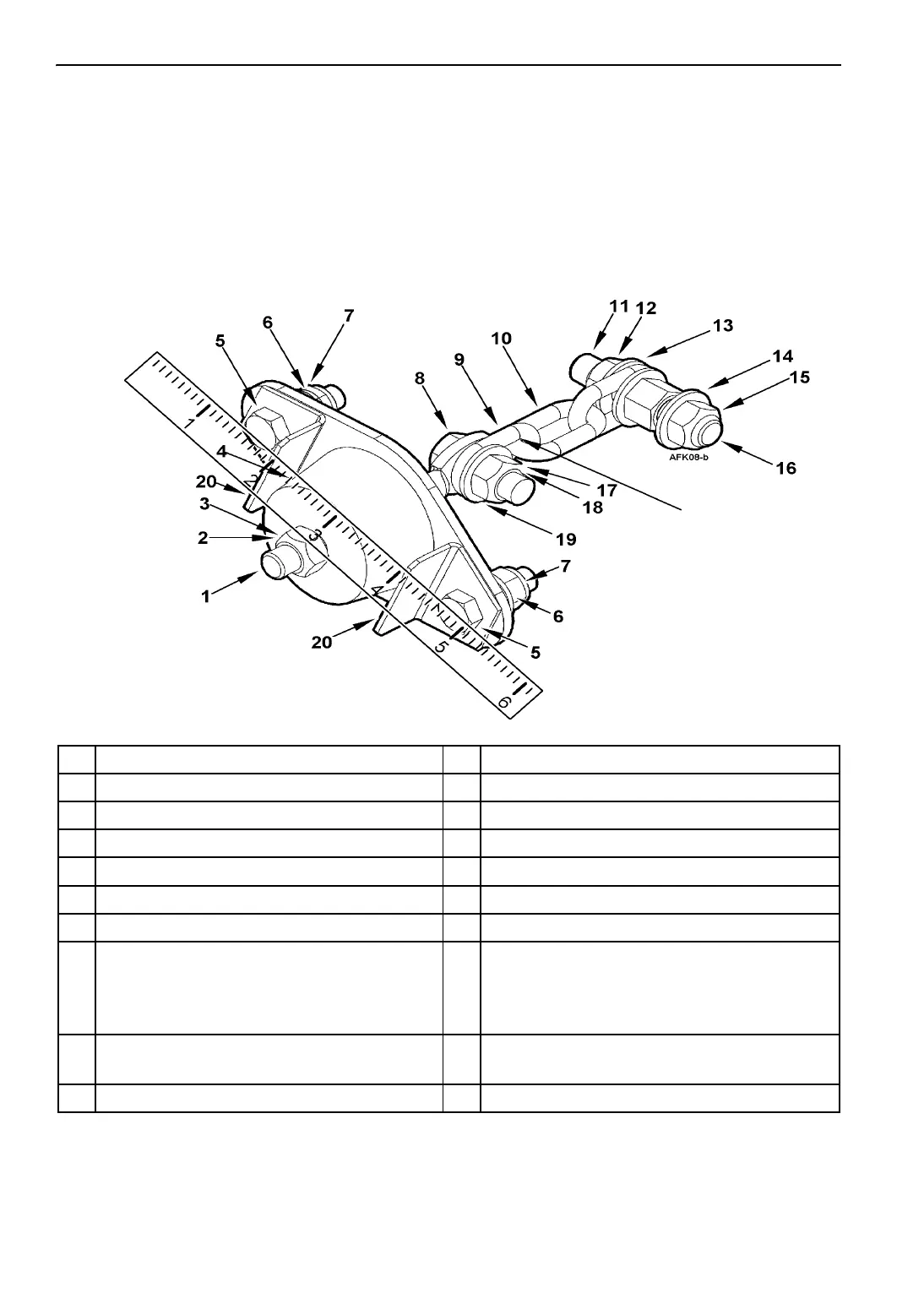

Restraining Mount Adjustment

Use this procedure for both the TK 3.95 and

TK376 engines. Install belts and remove slack.

After belt tension has been set (no slack). Check

seating in pulleys. Then proceed to tighten

locknut (#2) to compress the mount until the top

of mount is in the same plane as the gauge

brackets (#20). Use straight edge.to verify. Next,

retighten belts using TK Gauge (P/N 204-427).

Set belt tension to a reading of 55 to 60. Recheck

restraining mount alignment using a straight edge.

This is a blowup of balloon items for “TK 3.95

Engine Mounting Components” on page 114 and

“TK376 Engine Mounting Components” on

page 116.

Install chain on

“Depressed” side

of eye bolt.

1. Eye Bolt 11. Stud

2. Locknut (3/8 in.) 12. Locknut (HH)

3. Belleville Washer (3/8 in.) 13. Flatwasher (3/8 Galv.)

4. Vibration Mount 14. See Note 18.

5. Screw 15. Locknut (HH)

6. Flatwasher 16. This End Through Existing Hole In Engine Flange

7. Nyloc Nut 17. Locknut (HH)

8. Screw (3/8 in. SS) 18.

NOTE: Do not torque nuts to the normal

3/8 torque specification. This would cause

unnecessary distortion of the flatwashers. A

snug fit is all that is required.

9.

NOTE: Always install chain on indented

side of eye bolt

19. Flatwasher (3/8 Galv.)

10. 3-Link Chain 20. Gauge Bracket

Figure 144: Chain/Restraining Mount

Loading...

Loading...