1

GENERAL INFORMATION 1.1

Hydraulic System

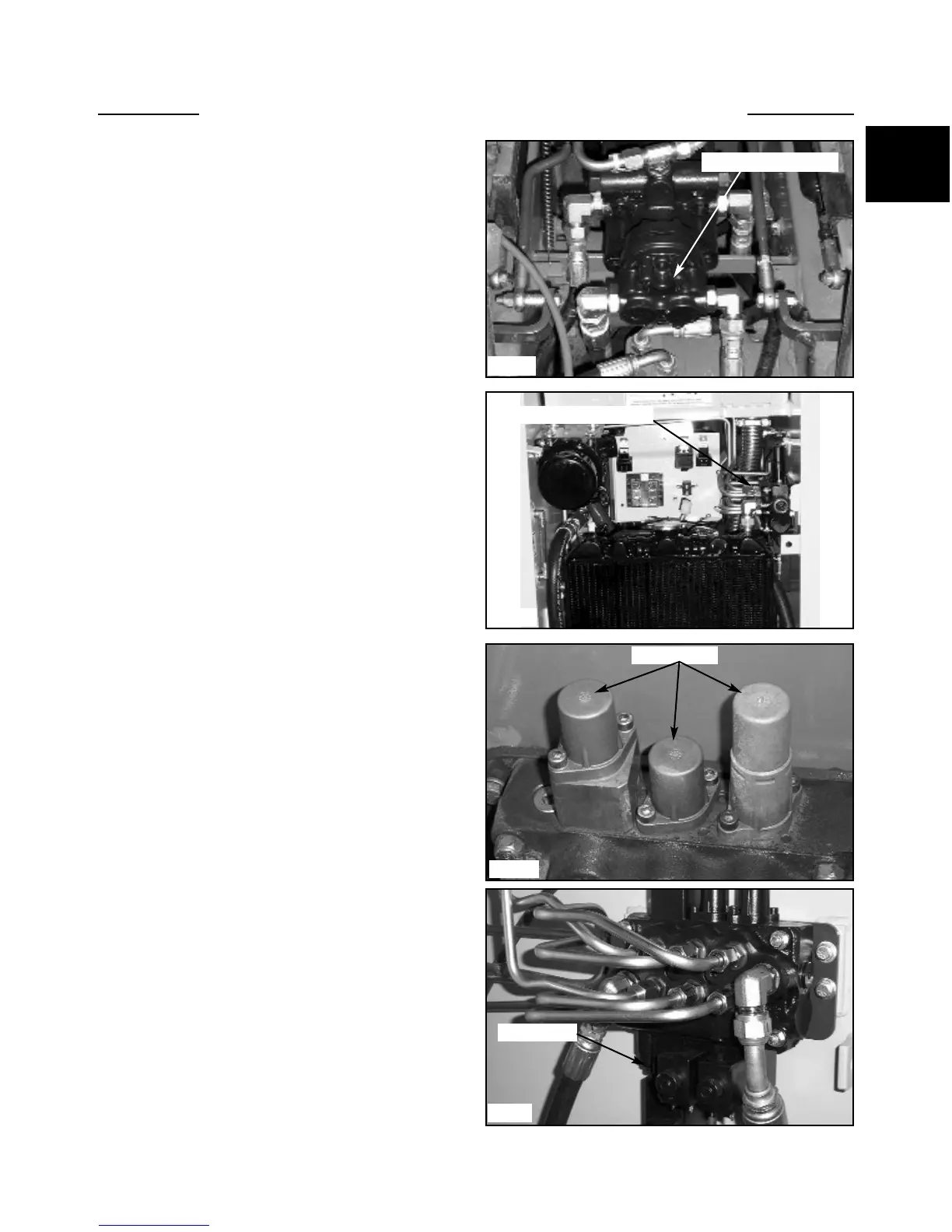

Oil is drawn from the hydraulic oil reservoir through a

100 micron element. From there it travels to the main

hydraulic pump. (fig. C5003).

•The hydraulic pump is a gear type which is driven by a

shaft and coupler through the hydrostatic drive pump at

engine speed. The oil then flows from the gear pump to

the hydraulic control valve. (C5248).

•The hydraulic control valve is equipped with an

adjustable relief valve which is adjusted to 2200 psi (148

bar). The control valve is a series type with 3 spools

(banks). The various spools activate the boom, bucket and

auxiliary hydraulic functions.

When the spools are in neutral, oil flows from the

hydraulic gear pump, through the control valve and

returns to the 10 micron hydraulic filter. From the

hydraulic filter, the fluid flows to charge the tandem

hydrostatic pump and pressurize the hydraulic brake

release system and then back to the hydraulic reservoir.

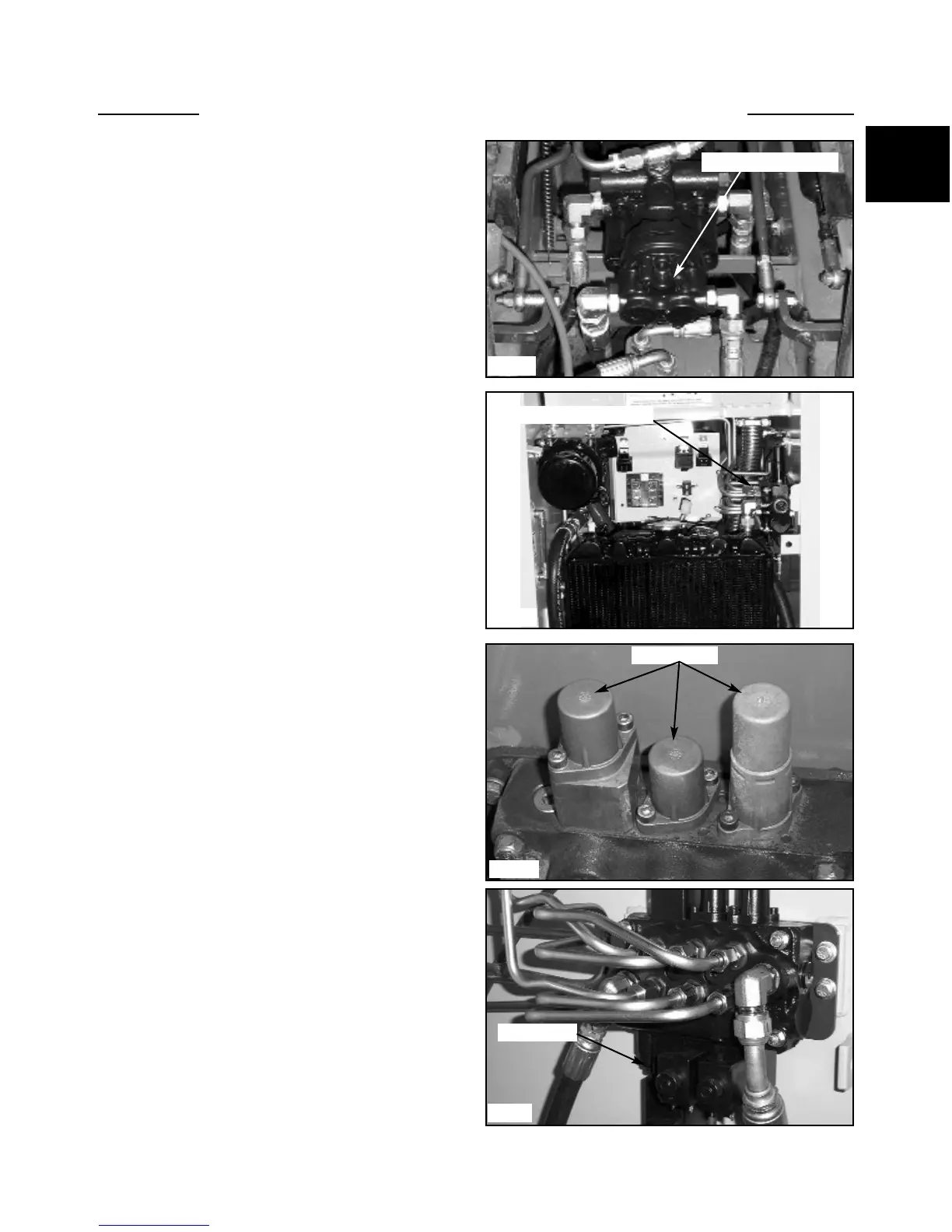

Each control valve section spool end contains a centering

spring which returns the spool to neutral when the foot

pedal, or control handle, is released. (fig.C5195).

•The boom section, on foot control operated loaders, has

a detent mechanism to hold the spool in the float position.

The auxiliary section is operated by foot pedal operation,

or may have an optional electrical solenoid operated

control, and may be engaged momentarily by the control

lever mounted switch, forward or reverse, or by engaging

the dash mounted toggle switch for constant power in the

forward direction only.

The system relief valve operates when ever a hydraulic

function has been restricted or overloaded (fig. C5063).

To protect against excessive pressure build up, the relief

valve opens and allows oil to return to the valve outlet.

The system relief valve is adjustable, and is preset at

2200 psi (148 bar).

•Load check valves are located between the ports of each

spool circuit. The function of the load check valve is to

hold the boom arms or bucket in position during initial

spool movement.

1-5

C5003

Control valve location

C5248

Gear pump Location

Relief valve

C5063

C5195

Spring return

Loading...

Loading...