4-5

4

Neutral Adjustment (con’t.)

IMPORTANT

Repairs or adjustment to the control lever system

may change the loader neutral position. Make sure

the loader is raised securely off the ground before

restarting the engine.

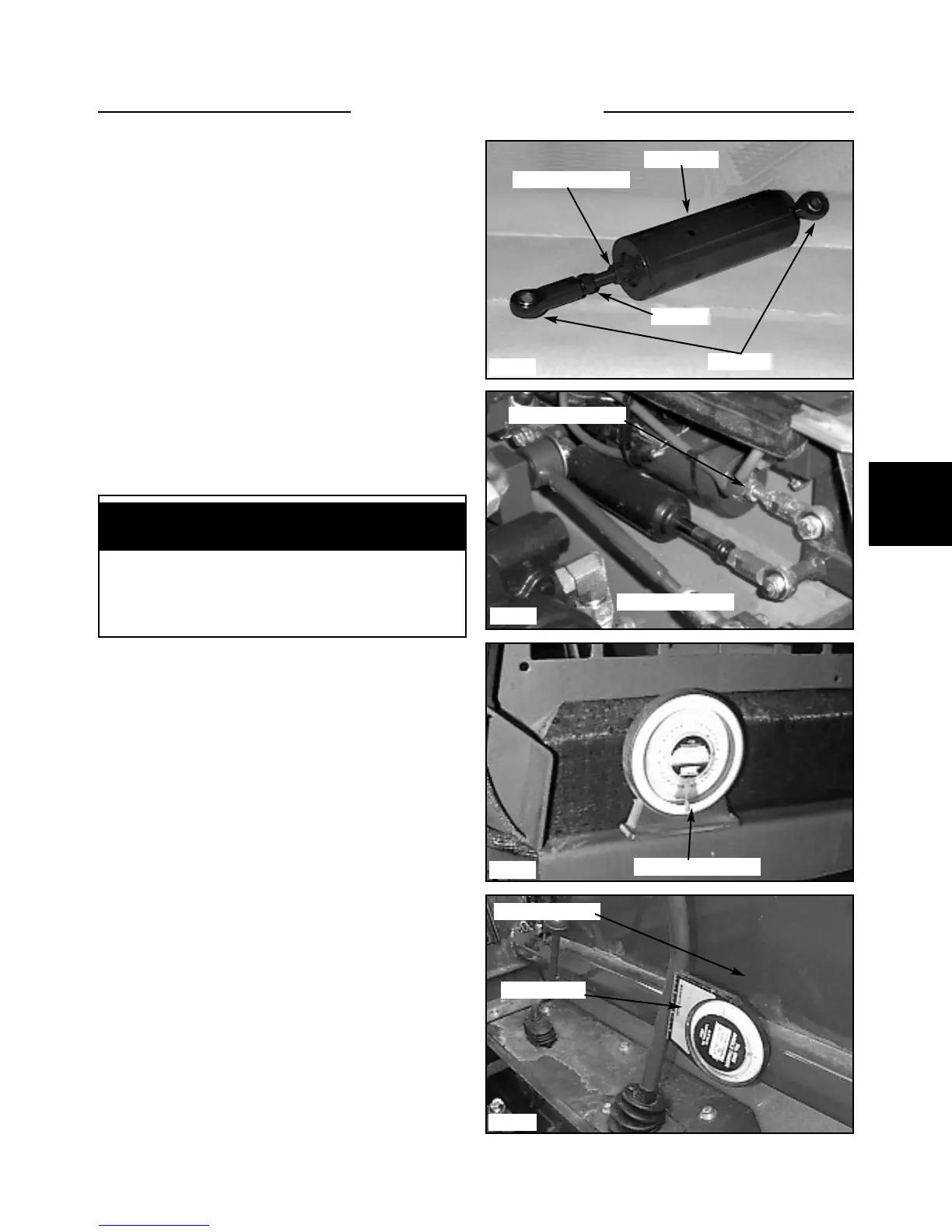

6 Loosen the 2 jam nuts next to the main body. (fig.

C1638, 5015)

7 Turn the 2 nuts away from the main body of the

hydroback.

8 Cycle the control lever several times.

9 Push the control lever rearward until you feel resis-

tance. Stop.

10 Turn the 2 jam nuts back toward the main body of

the hydroback until the nut just touches the flat washer.

11 Cycle the control lever again checking for a positive

feel. If you now have a positive neutral, tighten the 2 jam

nuts together and proceed to step 12, pg. 4-6. If the

hydroback still does not center, the hydroback has inter-

nal damage or wear. Replace the hydroback assembly

with a new one.

Hydro Back Replacement

Replacing the hydroback changes the steering control

lever angle and the neutral position. To correctly set the

angle after the hydro back has been installed:

1 Replace the hydroback by removing the 2 bolts locat-

ed at either end of the hydro back assembly.

2 Install the hydroback in the reverse order. Check the

steering control rod ends and replace them now if they

are worn.

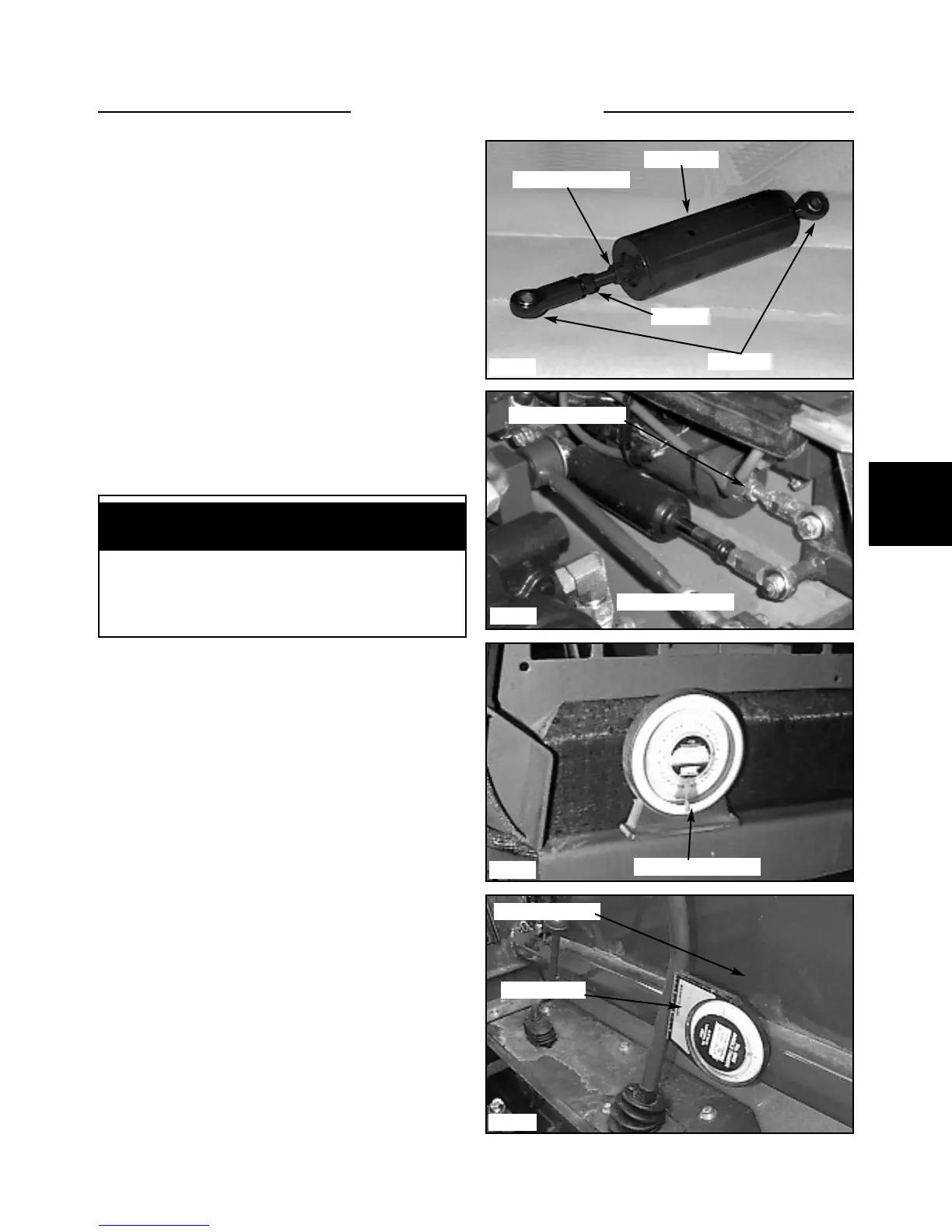

3 Use an angle finder to check the base measurement

angle the loader is sitting at. (fig. C2048) Note the angle

the loader is sitting at. This measurement will have to be

added or subtracted to the next measurement to give the

most accurate adjustment.

4 Attach an angle finder to the most vertical part of the

control lever. (fig. C2442)

5 Turn the hydroback threaded rod (fig. C5015) in or

out of the female rod end to move the control lever to a

reading of 12º leaning forward. Be sure to allow for

angle the loader is sitting at. (Base angle) Jam the nut

against the rod end when completed.

Make sure there is a minimum of 3/8’’ (6mm) of thread

holding the female rod end to the threaded rod.

6. Proceed to neutral adjustments, step 12, pg. 4-6.

STEERING 4.1

C1638

C5015

C2442

C2048

Jam nut

2 Detent jam nuts

Hydroback

Rod ends

2 Detent jam nuts

Angle adjustment

Note the base angle

Angle finder

Lean forward 9°

Loading...

Loading...