6-3

6

QUICK TACH 6.1

Preventative Maintenance

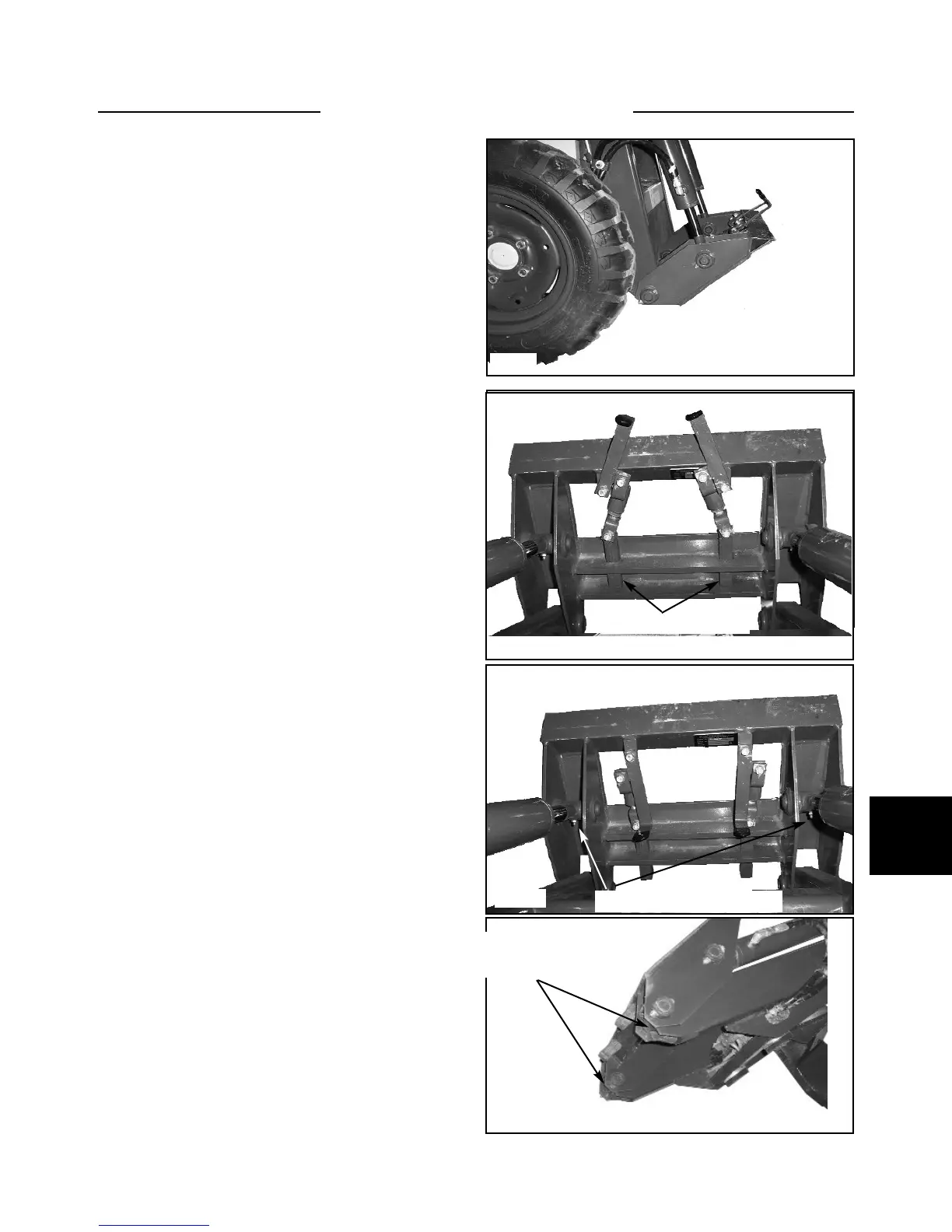

1 Remove any attachment from the loader, lower the

liftarms, roll the q-tach out to the position shown, engage

the parking brake and shut off the engine.(fig. C5639)

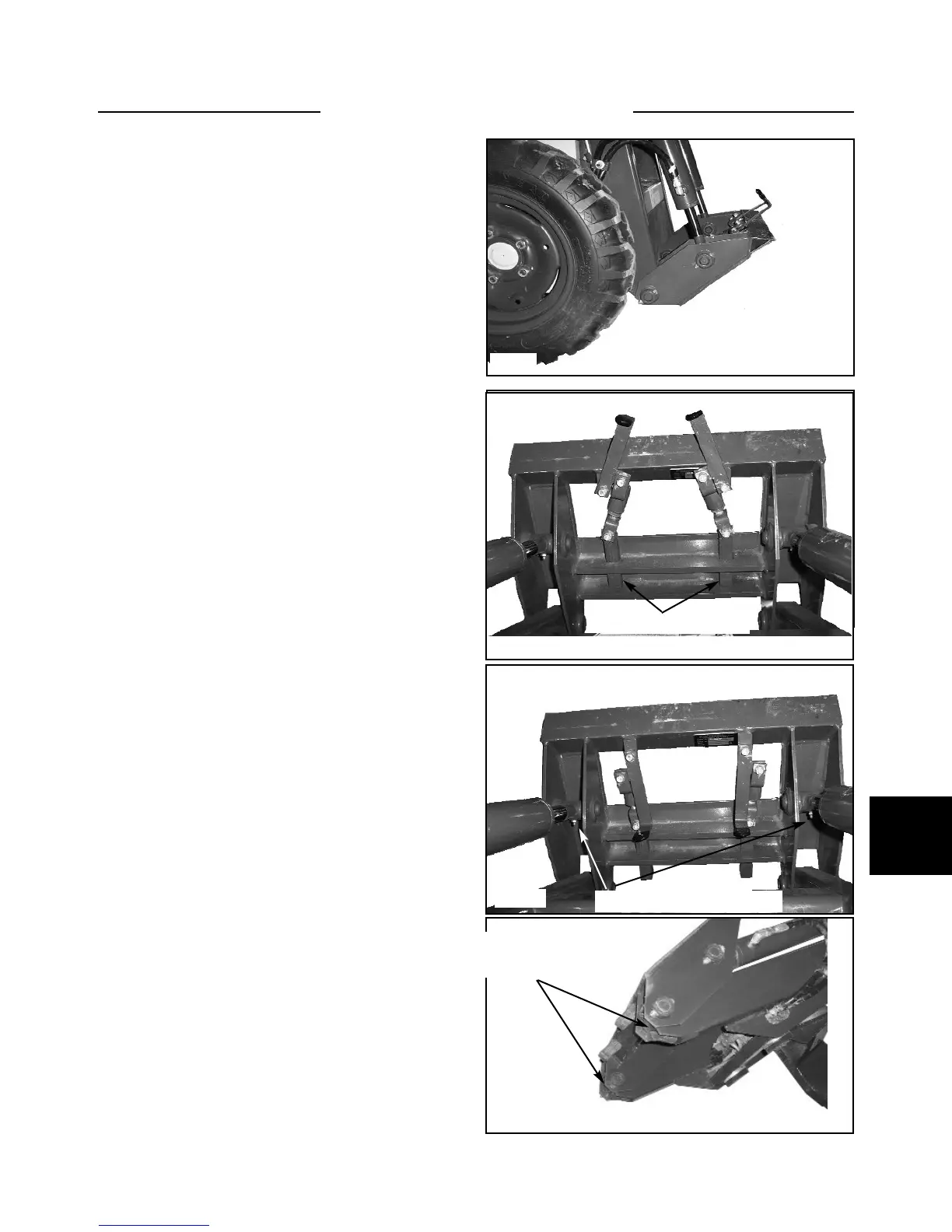

2 Clean any dirt build up around the linkages.

3 Inspect the linkages for loose nuts or bolts.

4 Inspect the springs and lock pin assemblies for dam-

age.

5 Check that the locking linkage works smoothly with-

out binding. If lock pin assemblies need lubrication, use

a small brush to apply grease to the sides of the pins. (fig.

C5637)

6 Lubricate the lower boom arm pivot pins and tilt

cylinder pins daily. Use a good quality, multi-purpose

lithium based grease.

7 Check the boom arm and tilt cylinder pins for wear

and if necessary replace.

C5639

C5637

C5192

Grease pivot

pins (L&R)

Q-tach pins unlocked

Q-tach pins locked

Tilt cyl grease nipples

C5192

C5638

Grease with brush

Loading...

Loading...