8

8-9

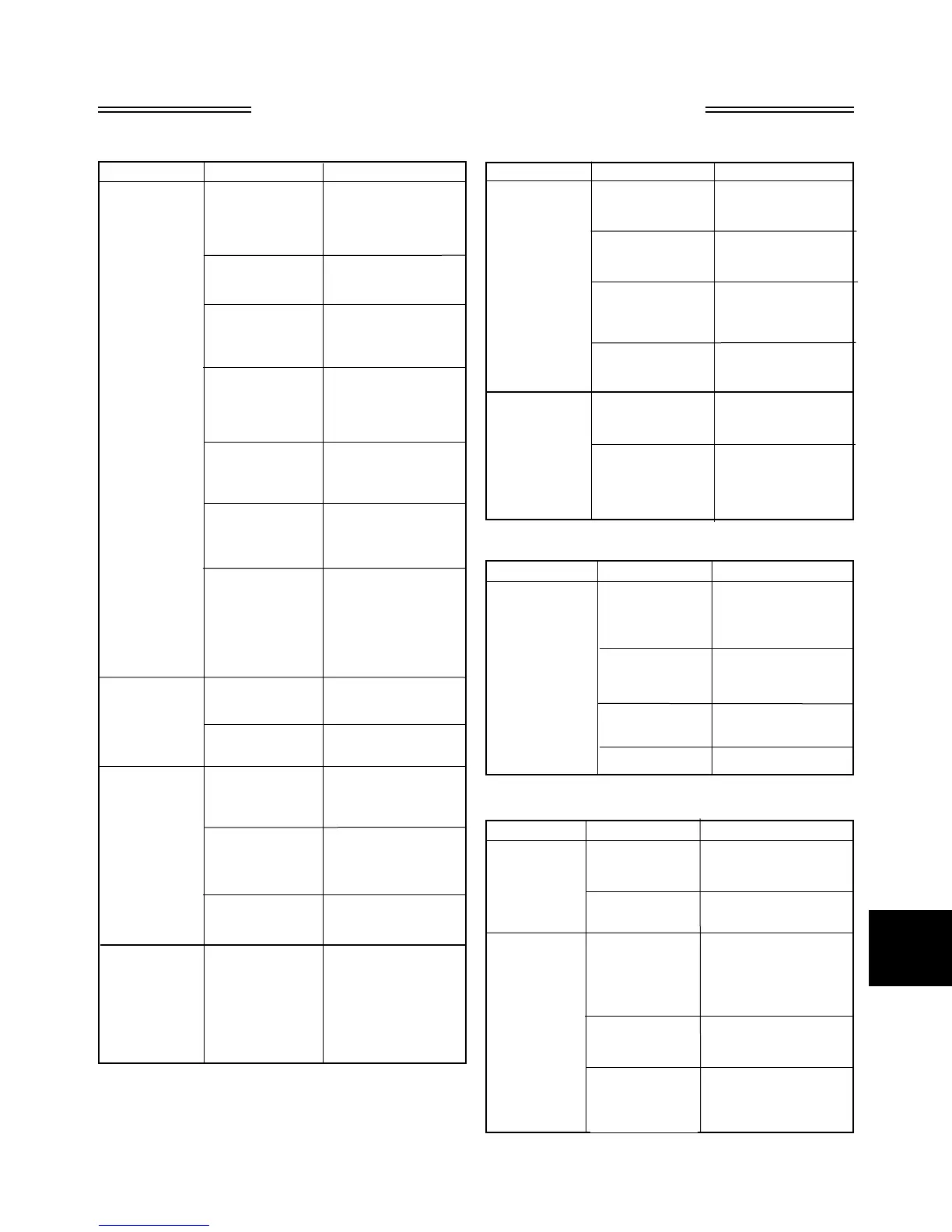

Final drive trans-

mission noisy

No lubricating oil

Parking brake

damaged or out of

adjustment

Axles have too

much end play

Chain loose

Check and bring oil to

the proper level. Use

10W30 SJ engine oil

Inspect and adjust or

replace damaged parts

Pre-load axle bearings

removing all end play

Replace chain

8.2B Final Drive Transmission

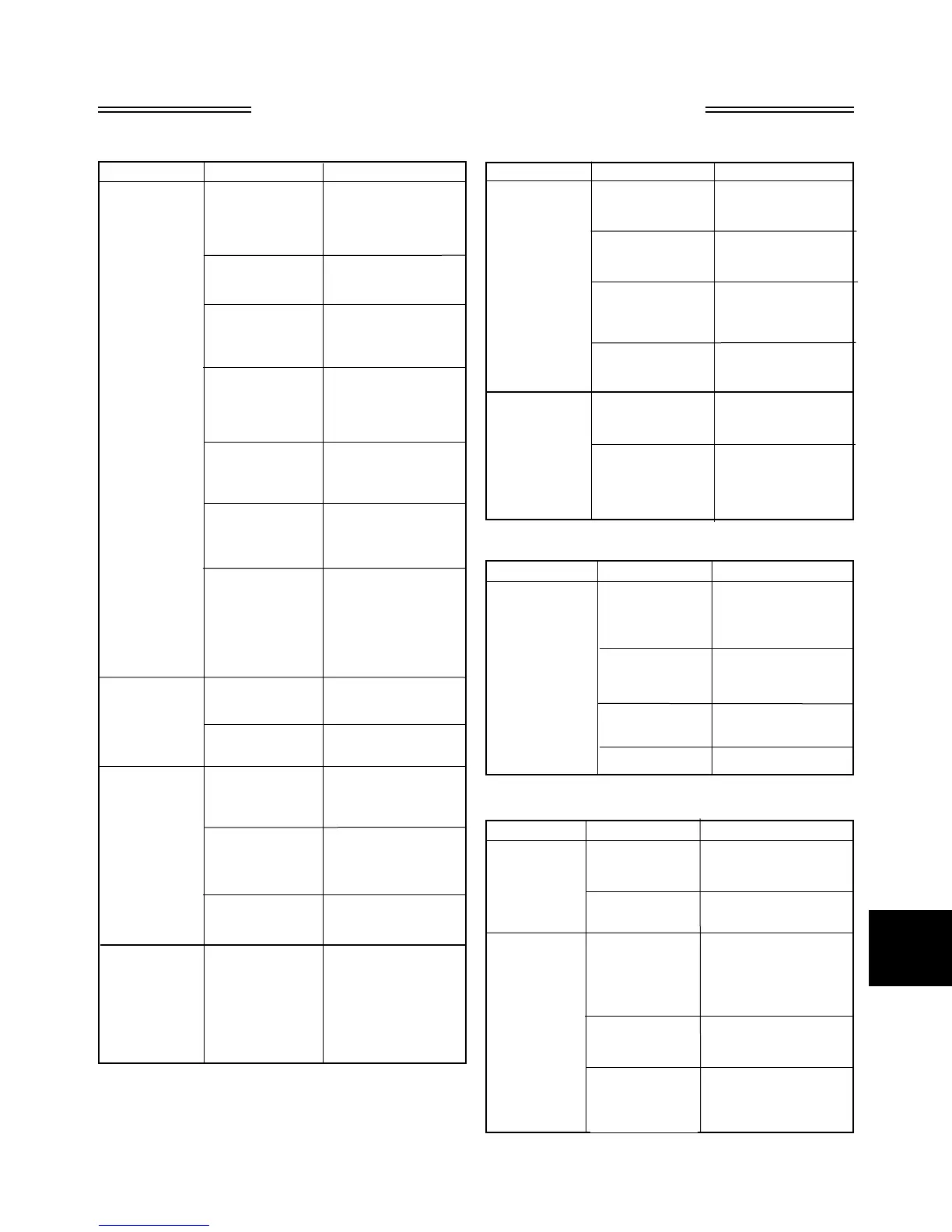

Brake will not

hold machine

Brake will not

release machine

Brake parts dam-

aged or worn

Brakes are disen-

gaged

Brake pins holding

in sprocket

Brake parts dam-

aged or worn

Consult your Dealer or

Thomas Service Dept.

Engage parking brake

With restraint bar down,

jog control levers back

and forth. If not releas-

ing consult Dealer or

Thomas service dept.

Consult your Dealer or

Thomas service Dept.

8.2C Park Brake

Symptom Cause Remedy

Symptom Cause Remedy

8. 2A Hydrostatic Drive 8.2A Hydrostatic Drive

Symptom Cause Remedy

No power on Reservoir low Replenish with

one side (both on oil 10W30 API

directions) SJ oil.

Check for hose or

fitting leak.

Disconnected Reconnect and adjust

control linkage linkage.

Groove pin Replace. Check

sheared on pintle lever for loose

pump pintle bolt or

lever excessive play.

High pressure Replace line. Ensure

line failure new line fits without

being forced. If

necessary stress

relieve.

Drive chain Replace chain or

failure connection link.

Motor shaft Inspect and repair

or key failure defective parts.

Check motor

mounting bolts.

Excessive Inspect and repair

internal defective unit. Flush

leakage in al lines and tank.

and/or motor Replace filter.

pump Check on type

of fluid used and

engine rpm.

No power on Defective relief Replace defective

one side (one valve valve.

direction only)

Damaged ball Disassemble and

check repair.

No power on Reservoir low Replenish with

both sides on oil 10W30 API SJ

(also loss of Check for hose or

hydraulic fitting leaks

power)

Universal Joint Inspect and repair

failure between damaged parts.

engine and pump

Damaged Disassemble and

ball check repair

Gradual loss Excessive Consult dealer or

of power as internal Thomas Service

machine leakage in Dept.

warms up pump and/or

motor

Symptom Cause Remedy

System erratic Air in system due Replenish with

and/or noisy to low oil level in 10W30 API SJ

reservoir oil.

Air in system due Check fittings

to leak at and tighten.

suction fitting

Internal pump or Consult your dealer

motor wear or Thomas Service

caused by Dept.

over speeding

Excessive play in Adjust linkage and

linkage or pintle tighten or replace

lever pintle lever.

Machine will Control levers Check that shields

not travel in a binding are not stopping

straight line in lever from full travel.

high range

Check for linkage

binding at spring

mount. Adjust

tracking.

TROUBLESHOOTING 8.2

Loading...

Loading...