1

CONTROL VALVE 1.3

Testing and Adjusting the Relief Valve Pressure

Hoses and gauges required for this test must be capable

of withstanding 3000 psi (207 bar) continuous pressure,

and hydraulic flow meter capable of measuring 30 gallons

per minute. (113 l/min) (fig. C5004) This test also

checks the status of the gear pump capacities.

Pressure fluctuations may be caused by restricted oil flow

through the relief valve. The relief valve may need

replacing when its filter is contaminated.

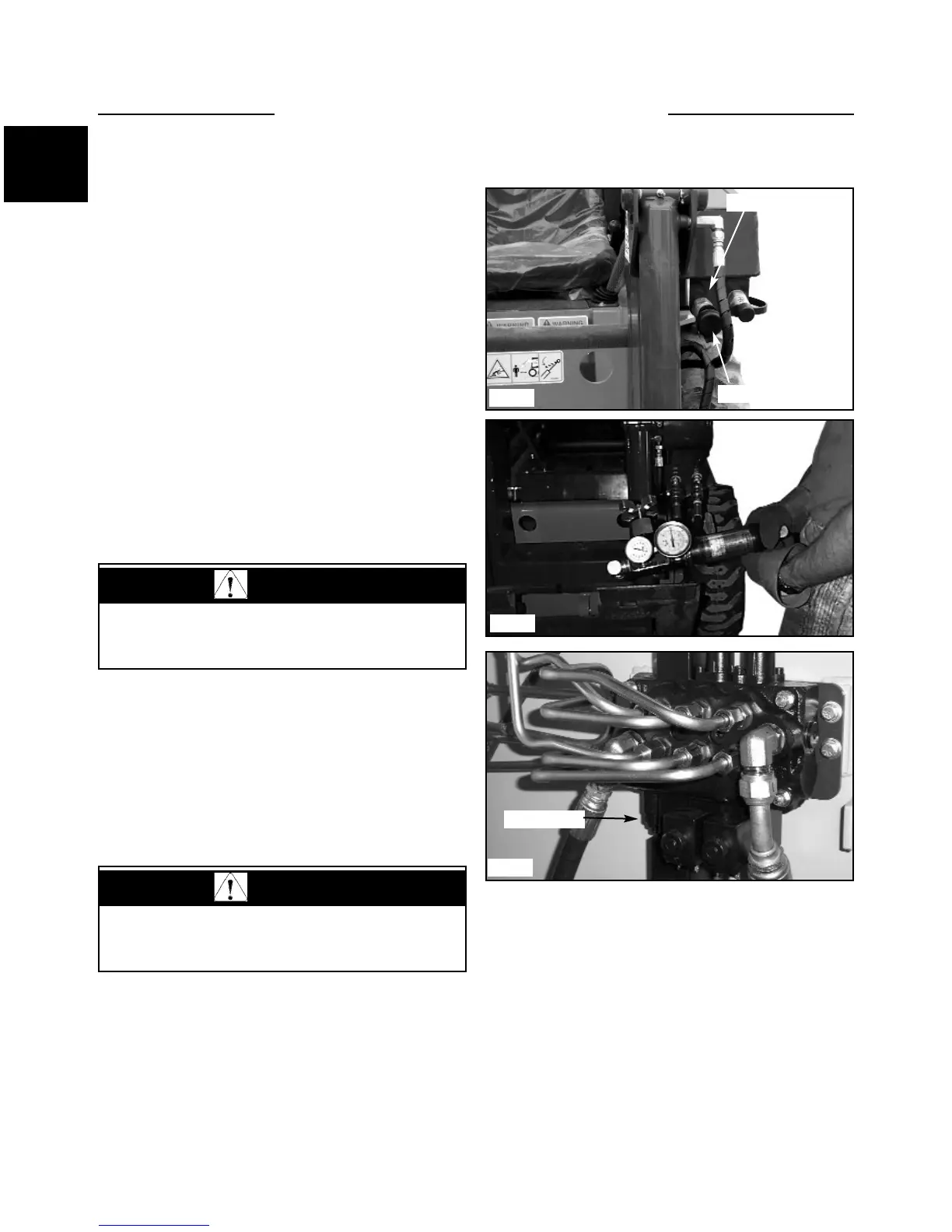

1 Install the flow meter / pressure tester to the auxiliary

hydraulic quick couplers. The female coupler attached to

the loader provides the power out when the auxiliary

control is engaged. (fig, C5004) Connect the flow meter

and pressure gauge inlet side to match the power out of

the female auxiliary coupler to prevent meter and gauge

damage. Be sure to connect a return line to the male

auxiliary hydraulic quick coupler. (fig. C2352)

2 Start the engine and engage the auxiliary hydraulic

system. Increase the engine speed to full operating rpm.

(See Section 7 for checking and adjusting engine speed to

3000 rpm plus or minus 25 rpm)

3 Turn the flow control valve on the flow meter to

restrict the oil flow down to 2 gal /min. (7.5 l/min ) As

you are turning the flow control valve, watch the pressure

gauge and make sure it does not go over 3000 psi (207

bar). Stop further adjustment immediately if the reading

goes over this setting. Shut off the auxiliary hydraulic

system and shut off the engine. Move to step 6 to make

initial setting.

1-10

WARNING

To prevent personal injury or damage to the loader,

do not adjust the relief valve while the engine is

operating.

CAUTION

Adjusting the relief valve setting too high may cause

damage to the gear pump.

C5004

Auxiliary couplers

Pressure out

C2352

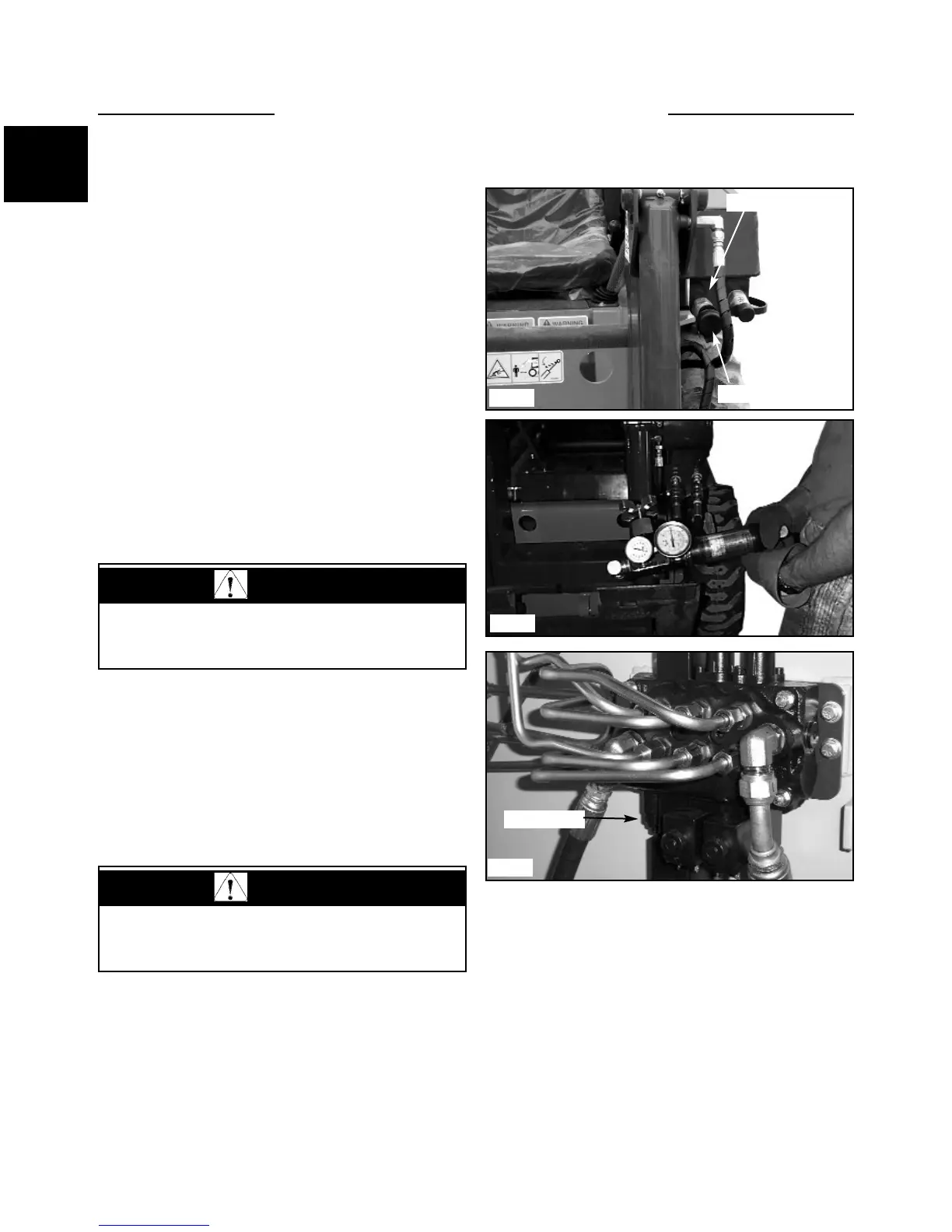

C5063

Relief valve

Loading...

Loading...