1

1-34

Before performing this test, ensure the control linkages

are not binding and the hydraulic control valve spools are

centering in the neutral position. Check the hydraulic

circuit for external leaks. These conditions will give the

same symptoms as a worn piston seal. If the cylinders

under pressure are sluggish or stop functioning, these

would indicate that oil is leaking by the cylinder piston

seal. The following test can be performed to check the

cylinder piston seal.

1. Remove any attachment and block the loader

securely with all 4 wheels off the ground using

appropriate jack and stands.

2. Retract the cylinder(s) to be tested. Shut off the

engine and cycle the controls to release the hydraulic

pressure. Have a container can ready to catch any waste

oil to prevent environmental contamination.

3. Disconnect the fixed end hose from the cylinder to be

tested. Cap the hose with a plug to prevent contamination.

4. Start the engine and cycle the control(s) as to retract

the cylinder. Do not over activate the controls as to place

in the detent position. Have a container can ready to catch

any waste oil to prevent environmental contamination.

5. Repeat for both cyclinders.

6. If oil leaks from the cyclinder port the seals are bad

and need replacement. If no oil leaks you may need to

check the load check valves or spool wear in the

hydraulic control valve.

7. Connect the hydraulic hose to the cyclinder ports if

no further servicing is required.

Testing the Piston Seals

HYDRAULIC CYLINDERS 1.4

WARNING

Use extreme caution when checking the hydraulic

system for leaks. Fluid under pressure can penetrate

the skin and cause serious injury.

Allowable boom or bucket cylinder drop: 1.5” in 3

minutes, @ loaded rating and operating

temperature.

IMPORTANT

C5008

C5004

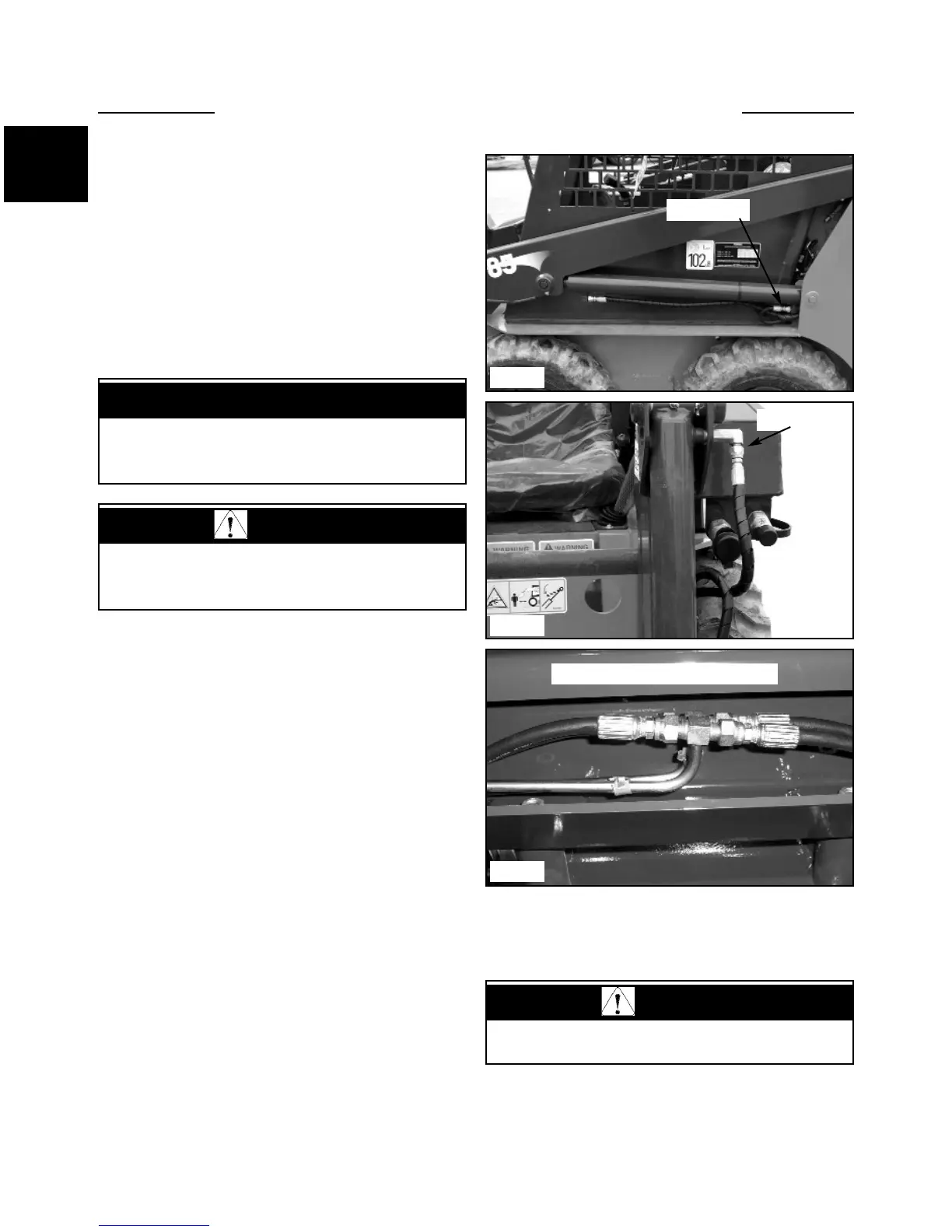

Fixed end

Fixed end

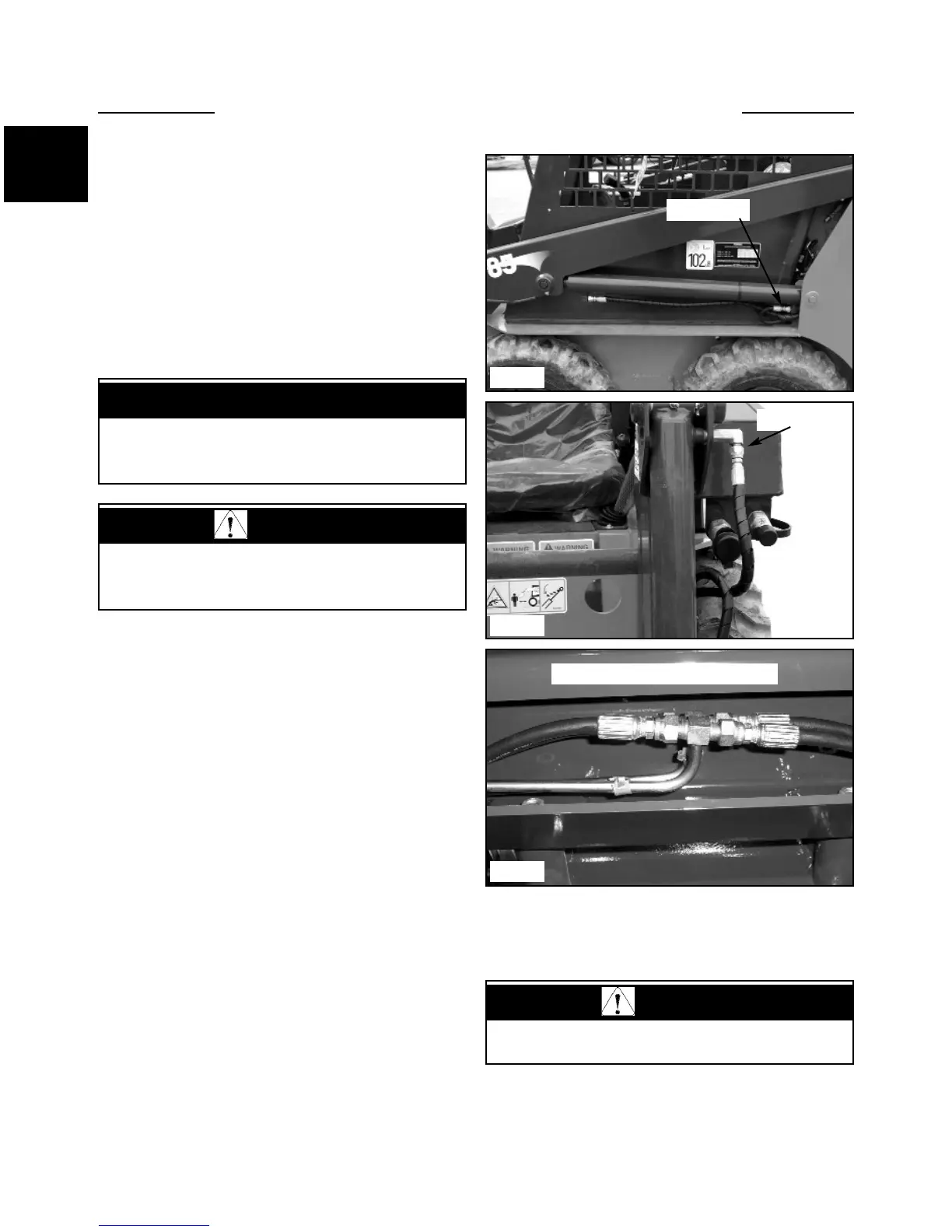

C5067

Hydraulics under liftarm step

WARNING

Never repair or tighten hydraulic lines while engine

is operating or the system is under pressure

Loading...

Loading...