2-17

2

TANDEM PUMP REPLACEMENT 2.10

IMPORTANT

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs

on all open line and ports.

Upon reassembly, inspect the outside area of the tandem

pump housing for damage that may have occurred in tran-

sit or handling.

1 Attach a lifting device to the tandem pump.

2 Install the pintle levers onto the pump, grease the

rear spline.

3 Place the pump into the loader, slide the u-joint onto

the spline while guiding the pump into it’s mounting loca-

tion. Insert mounting bolts and tighten to 20-25 ftlbs

torque. Remove lifting device.

5 Install the fittings removed from the old pump into

the new pump. Reconnect the hoses.(fig. 4838 page 2-4)

Torque the fittings and hoses according to Torque Chart

in Section 2.13 page 2.53.

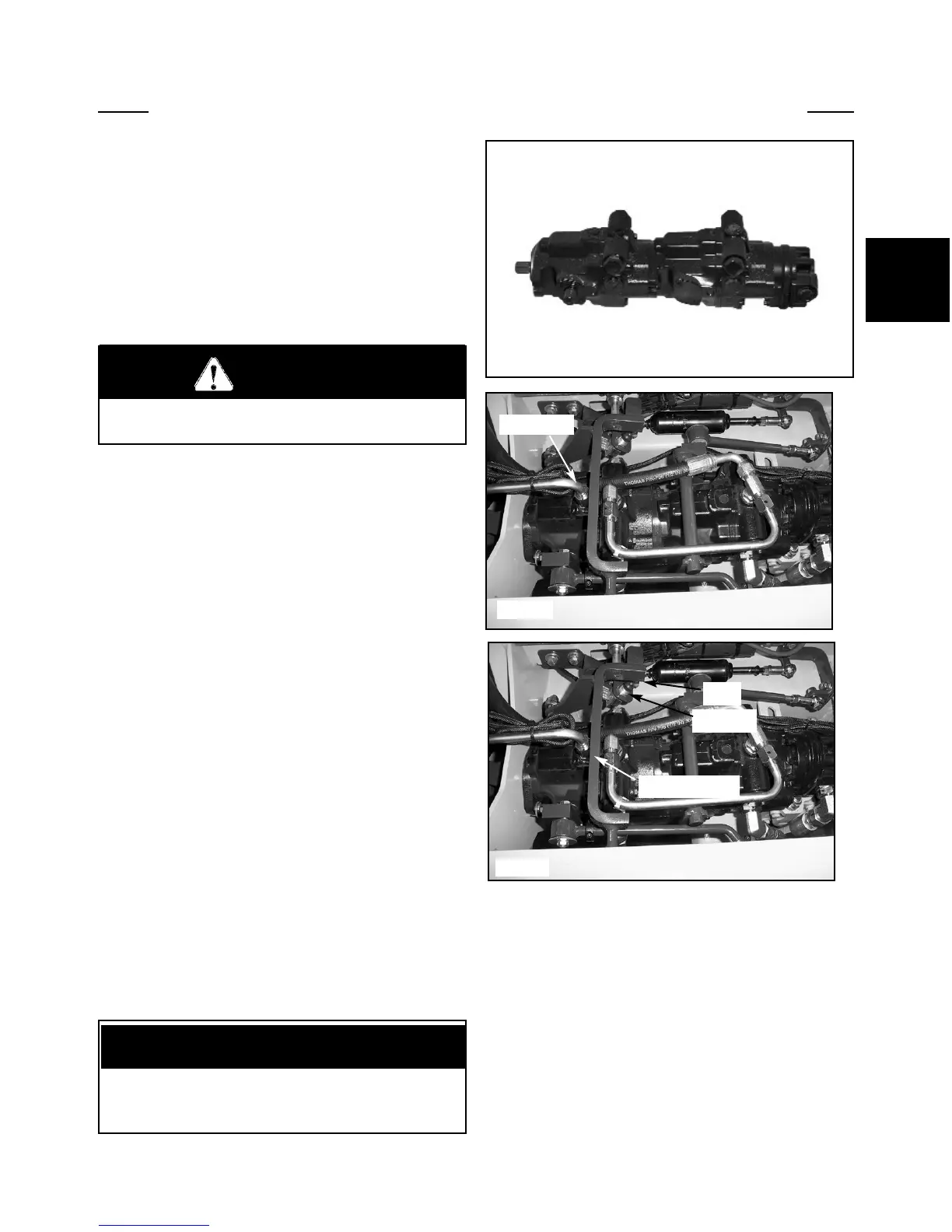

6 Before connecting drain tubing,(fig. C5207a) fill

pump case with hydraulic oil.

7 Install brake shaft and switch mount. Adjust switch

mount so that switches make contact with brake shaft

when the restraint bar is down. Check to make sure

switches are closed.

When the restraint bar is up, there should be a gap

between the switches and the brake bar. The switches

should now be open. (C5207b)

8 Install the control lever linkages and the limiter bar.

9 Follow the start-up procedure in section 2-8 for prop-

er start-up with a new pump.

10 Once loader is started, follow the procedures in

Chapter 4 for proper Neutral Adjustment, Tracking

Adjustment and Limiter adjustment.

WARNING

To prevent personal injury, do not attempt to lift

heavy objects without assistance.

C5072

C5207a

Case drain

C5207b

Switches

Gap

Brake Shaft

Loading...

Loading...