FFS2000 Series Chapter 3: Description

Page 6 TTN047338-D02

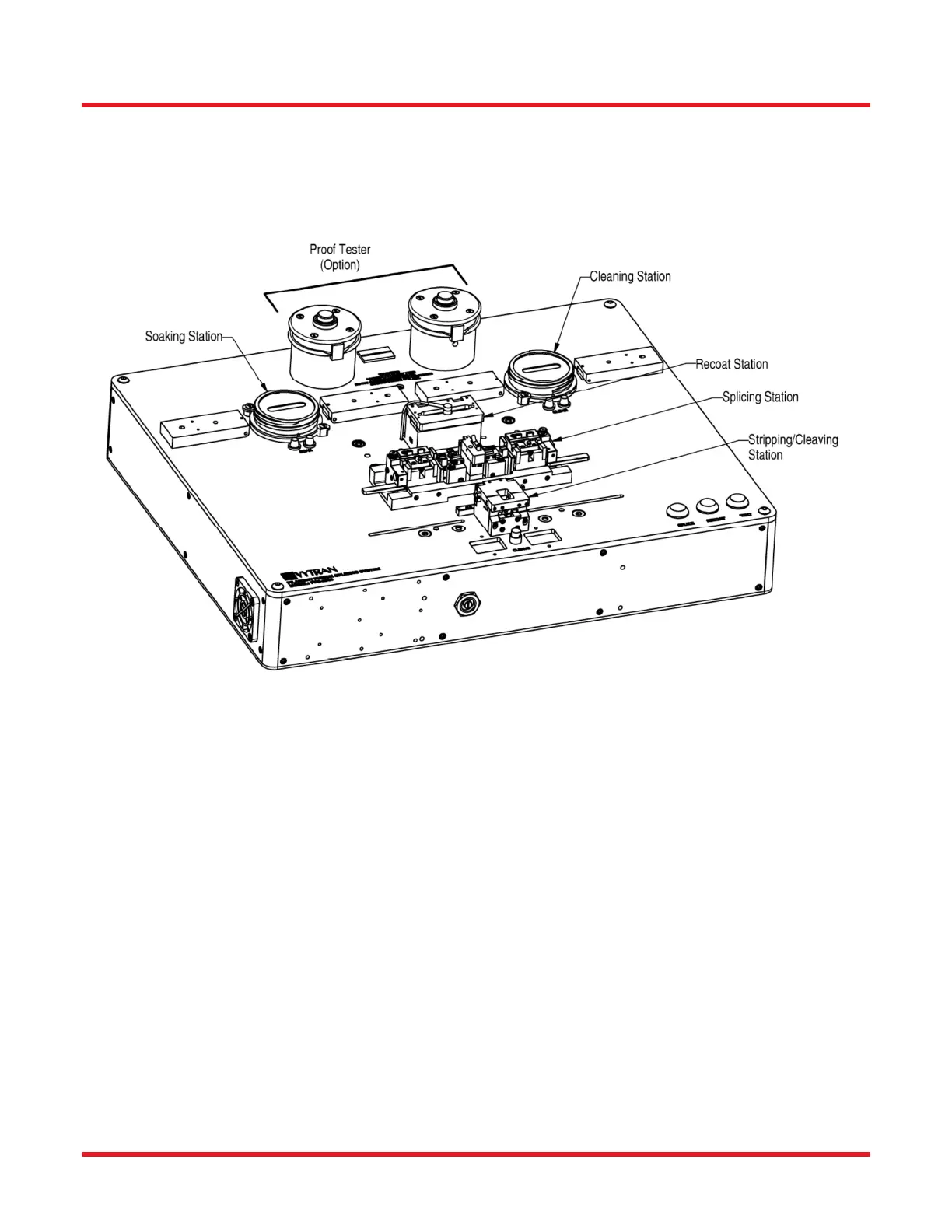

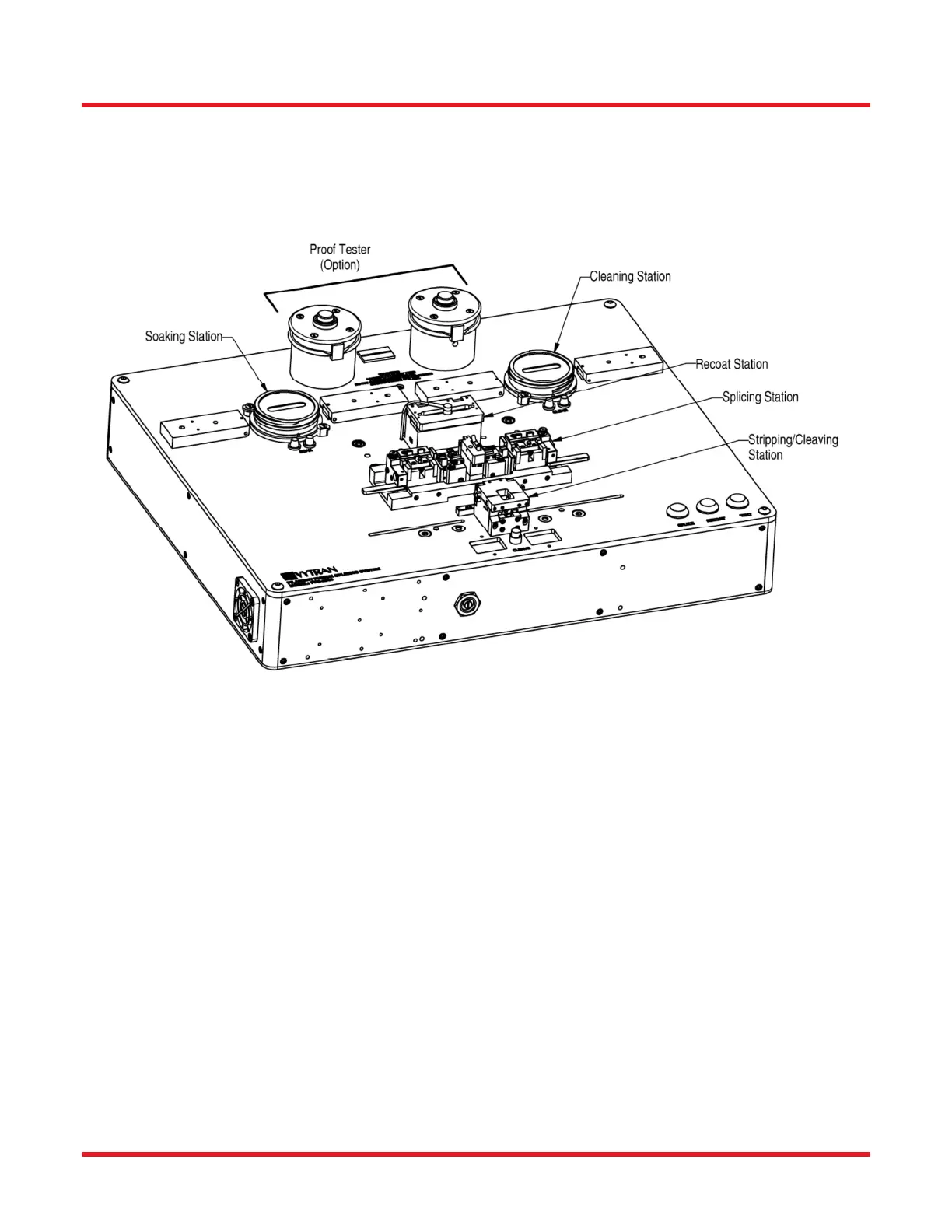

3.5. System Overview

The splicer workstation (splicer) is the main component of the FFS2000 Series splicing system. It performs all the

splicing process steps: soaking, stripping, cleaving, cleaning, splicing, recoating, and proof testing. The PC and

gas supply, as well as peripheral components such as an optical power meter, are connected to the splicer back

panel.

Figure 1 System Overview

The following subsections describe the components of the splicer workstation in the order of use during a splice

process.

3.5.1. Fiber Holding Block and Transfer Jig

Left- and right-hand fiber holding blocks (FHBs) are used to provide an efficient, convenient, step-by-step method

for preparing the fibers prior to splicing. The FHBs are also used in conjunction with a transfer jig to position the

fiber for splicing and to transfer the completed splice to the recoat station.

In addition to simplifying the handling of the fiber throughout the splicing process, the FHBs and transfer jig also

improve the consistency and strength of the splice by precisely positioning the fiber for each step. Fiber holding

blocks are sold separately from the FSX2000PM base unit, but are installed and factory-aligned with the purchase

of the system.

Loading...

Loading...