FFS2000 Series Chapter 8: Recoat

Page 54 TTN047338-D02

Cure times are dependent on the mold size and recoat material, but they range from approximately 12 - 15

seconds for the Thorlabs Item # RM280 mold assembly with high-index Thorlabs Item # AB950200 recoat

material to 30 - 60 seconds with the low-index Thorlabs Item # PC373 recoat material. If you would like to use the

low-index material with your FFS2000 series system, we recommend contacting Thorlabs for assistance.

WARNING

Do not look directly at the recoat assembly while the recoat lamps are on. The recoat lamps emit ultra-

violet radiation which can cause damage to the eyes. The mold top must be closed during recoat lamp

operation.

To cure the fiber coating, use the following procedures:

1. Press the Recoat button to turn on the UV lamps. The recoat lamps will shut off automatically after the

set cure time.

2. To remove the recoated splice, first raise both FHB tops. Next, raise the recoat mold assembly top.

3. Remove the recoated fiber from the mold assembly. The fiber may remain tacked to either the top or

bottom mold plate. In this case, it may be necessary to gently pull on the fiber to release it.

8.5. Diagnostics

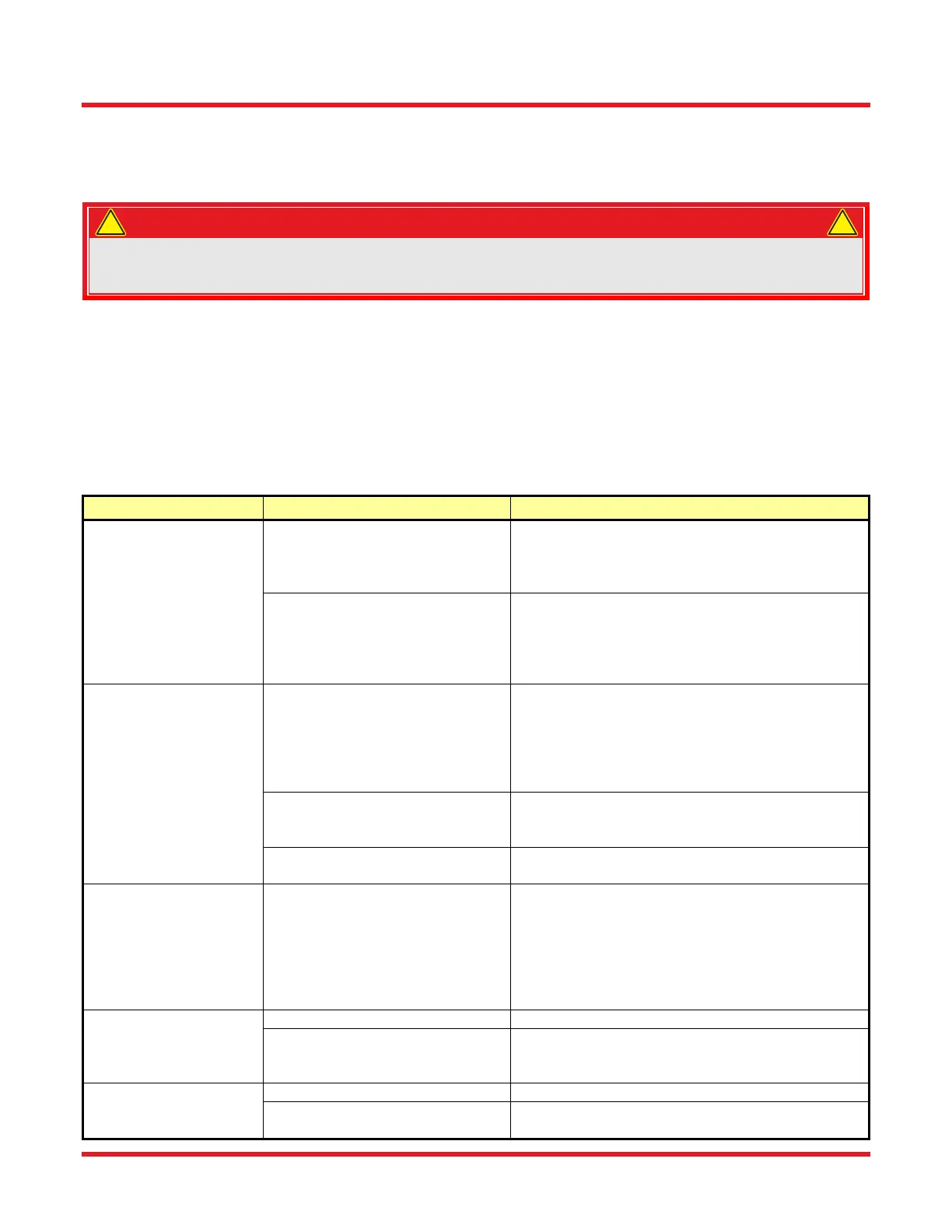

Problem Possible Cause Solution

Fiber snaps when

mold top lowered.

Recoat mold not properly aligned

to fiber.

Check that the fiber is seated in the FHB V-

grooves correctly. Check that the Tension Fiber

Process is in the splice sequence and that it has

been allowed to execute.

Grooves on recoat mold plate

and cap do not line up.

Ensure that the FHBs and Transfer Jigs used are

not those from another machine.

Align mold to single piece of stripped fiber

stretched between FHBs in transfer jig.

Contact Thorlabs for splicer servicing.

Material flows

excessively outside

of mold cavity or

does not flow down

mold cavity

(“puddling”).

Recoat mold plates are dirty. By far the most common cause of recoat

problems. Dirt between quartz mold plates will

not allow them to lay flush, causing the acrylate

to flow excessively outside the mold cavity. The

recoat mold plates should be cleaned as

described in Section 8.2.

Fiber is not taught in FHBs. Set up Post Splice Tension or ensure that the

Post Splice Tension process executes before

removing the Transfer Jig from the Splice Station.

Grooves on recoat mold plate

and cap do not line up.

Contact Thorlabs for servicing.

Flashing forms along

the length of the

recoat.

Cure time too long. This will increase the modulus of the coating and

make it stiffer. In the future, decrease the cure

time. This flashing can generally be removed by

wiping the recoated section with a dry lens tissue.

For very tough flashing, it may be necessary to

use the gray abrasive square to gently rub off the

flashing material.

Recoat feels tacky or

can be easily rubbed

off by pulling the

fiber between fingers.

Cure time too short. Increase the cure time.

One of the Recoat bulbs is

burned out.

Replace the recoat bulb. Dispose of the old bulb

with general waste or with glass waste.

Bubble in recoat.

System refilled but unpurged. Purge injection system and any tubing.

Supply of recoat material

expiring.

Refill injection system. Purge system until the

recoat flows bubble free.

!

!

Loading...

Loading...