FFS2000 Series Chapter 3: Description

Page 14 TTN047338-D02

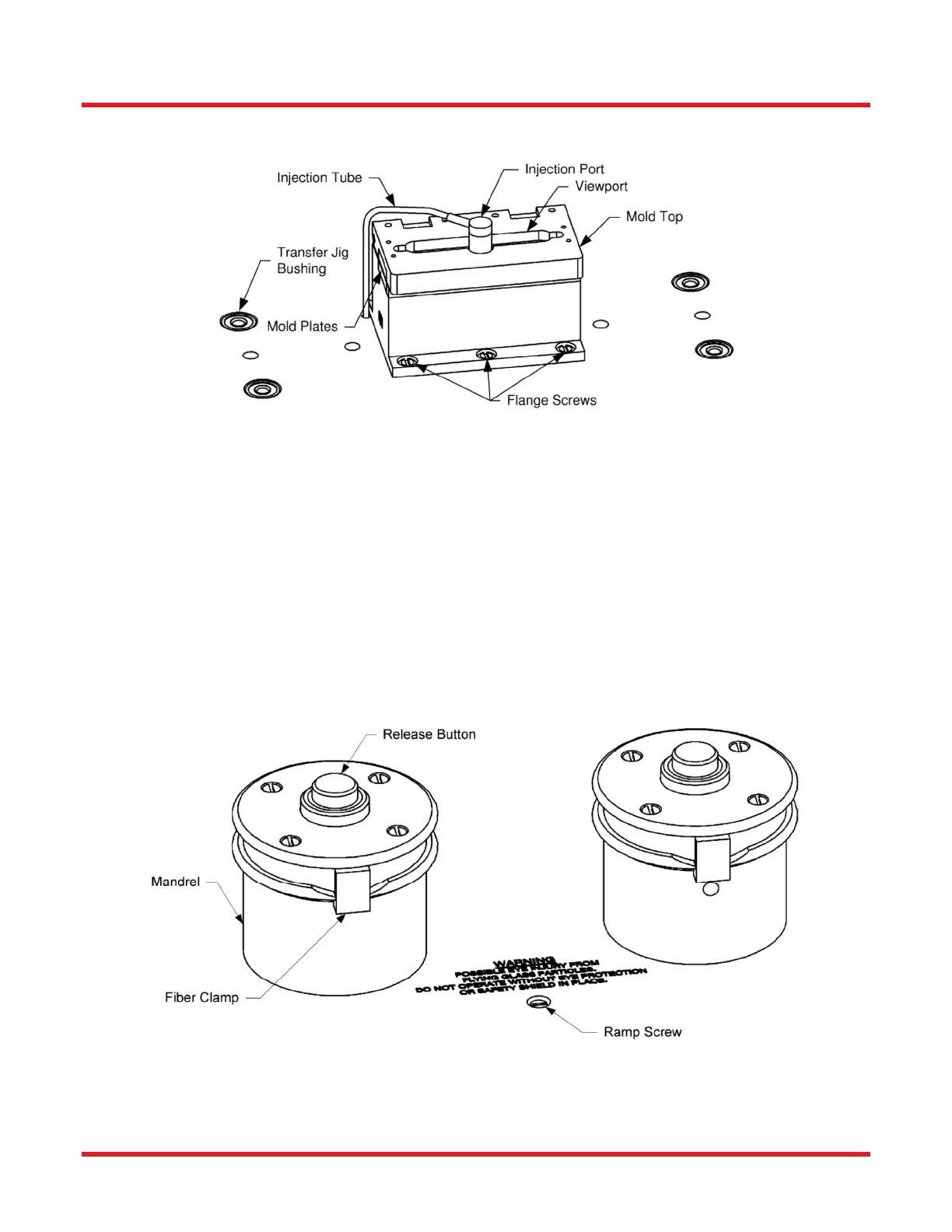

Figure 11 Recoat Station

Injection Port: The injection port is used to inject the UV acrylate into the mold cavity.

Viewport: The viewport allows the user to watch the UV acrylate as it flows into the mold cavity.

Fused Quartz Mold Plates: The mold plates form a mold cavity for the UV acrylate material.

Flange Screws: Flange screws are used to secure the position of the recoat station assembly.

Transfer Jig Bushings: The bushings are used to position the transfer jig at the splice station.

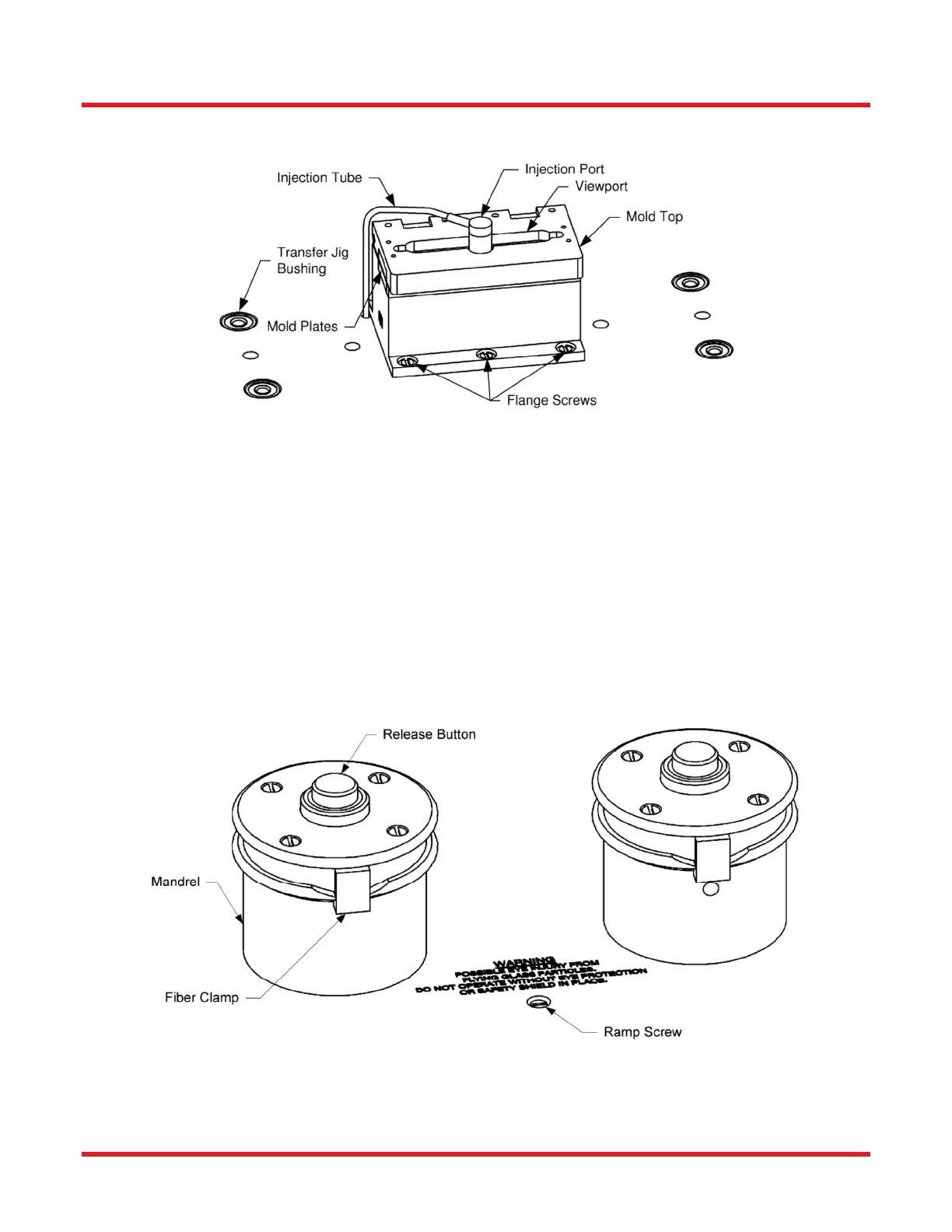

3.5.9. Proof Test Station (Item #s FFS2000PT and FFS2000WS)

The proof tester can be used either to determine the breaking strength of a fiber or to ensure that a fiber or fusion

splice meets a minimum strength requirement. Fiber is tested by placing it between the two mandrels. The ends

of the fiber are wrapped once around each mandrel and held in place by an integral clamping mechanism. A load

is automatically applied to the fiber by the rotation of one of the mandrels. The proof test or breaking load level is

measured via a load cell and is recorded by the software interface.

Figure 12 Proof Test Station

Loading...

Loading...