FFS2000 Series Chapter 6: Fiber Preparation

Rev B, July 21, 2017 Page 37

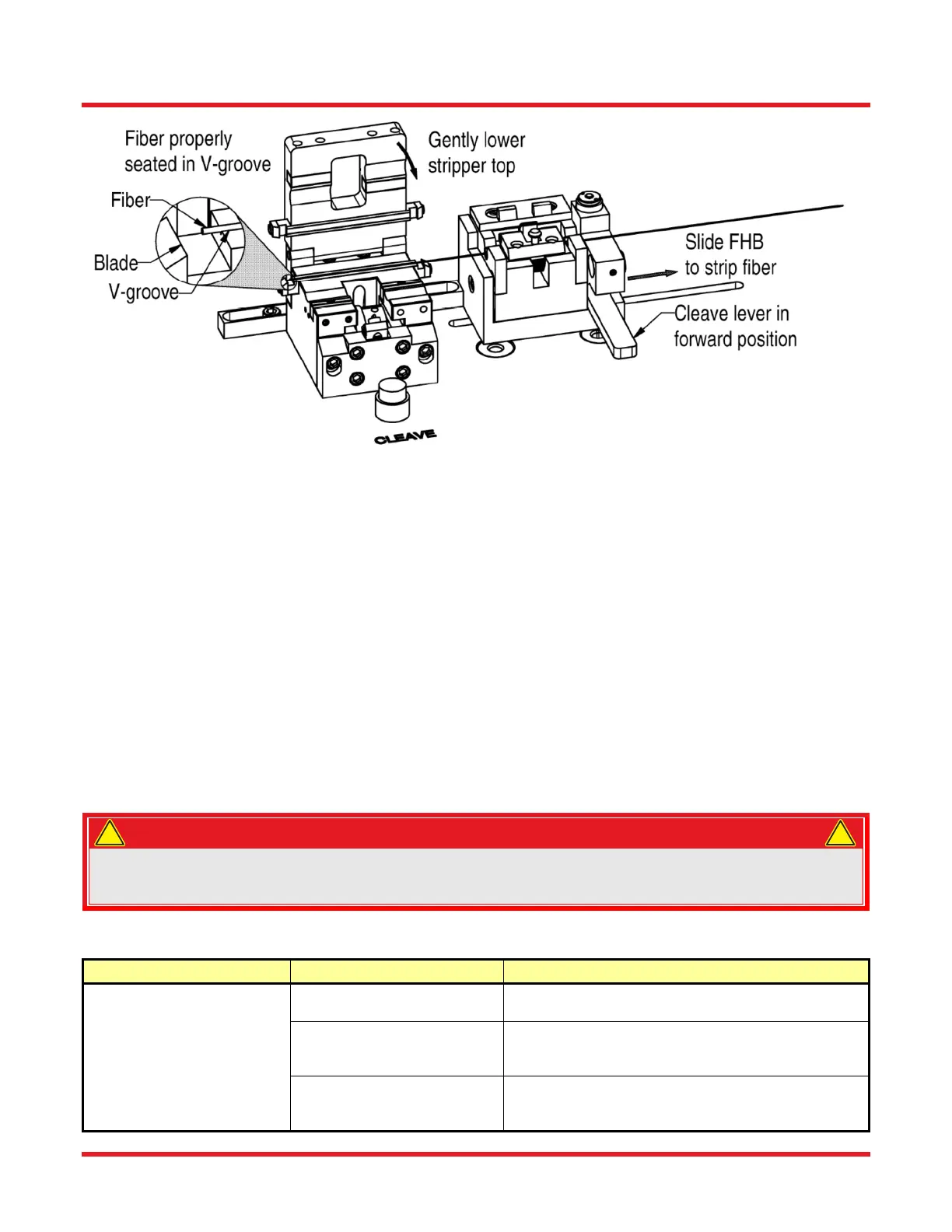

Figure 39 Stripping Procedure

The coating should strip off with a light sliding force. In some cases there may be some debris still attached to the

Fiber, but so long as these come free during the clean operation this is not cause for concern. It is only important

that the fiber is completely clean when loaded to the Splice Position. If the remaining cladding adheres tightly to

the fiber, and this occurs repeatedly, then there may be a problem either with the blades themselves, or their

setup.

Some fibers have an inner as well as outer buffer coating. Some manufacturers make these two coatings of

different materials. For example, certain fibers have an inner coating comprised of a soft silicone material. These

fibers tend to strip evenly, although the resulting stripped coating pieces will not be in a tube form. If such a

silicone buffered fiber is stripped, the residue should be dissolved using an appropriate silicone solvent and

properly rinsed before cleaving the fiber. Thorlabs can suggest manufacturers of suitable silicone solvents that

may be appropriate.

Raise the top of the Cleave Block and remove the stripped coating and all particles from the V-groove and around

the Stripper Blades. Use the optional vacuum cleaning system or a soft toothbrush (provided), and place a free

hand around the rear of the Cleave Block when cleaning.

WARNING

Do NOT clean the V-groove insert with solvent when the vacuum is turned on. The solvent will be

drawn into the vacuum system and will cause internal damage. If the V-Groove appears to be

damaged, replace the inserts.

6.2.4. Diagnostics

Problem Possible Cause Solution

Vacuum won’t hold fiber

in FHB V-grooves.

FHB V-Grooves are dirty. Clean the FHB V-grooves with the soft brush

(provided).

Obstruction present under

dunking jig.

Make sure that the area underneath the dunking

jig is free of dirt particles. If necessary clean the

surface with a mild soap.

Bad or missing O-ring on

the underside of the

dunking jig.

Contact Thorlabs for a replacement part.

!

!

Loading...

Loading...