FFS2000 Series Chapter 6: Fiber Preparation

Page 36 TTN047338-D02

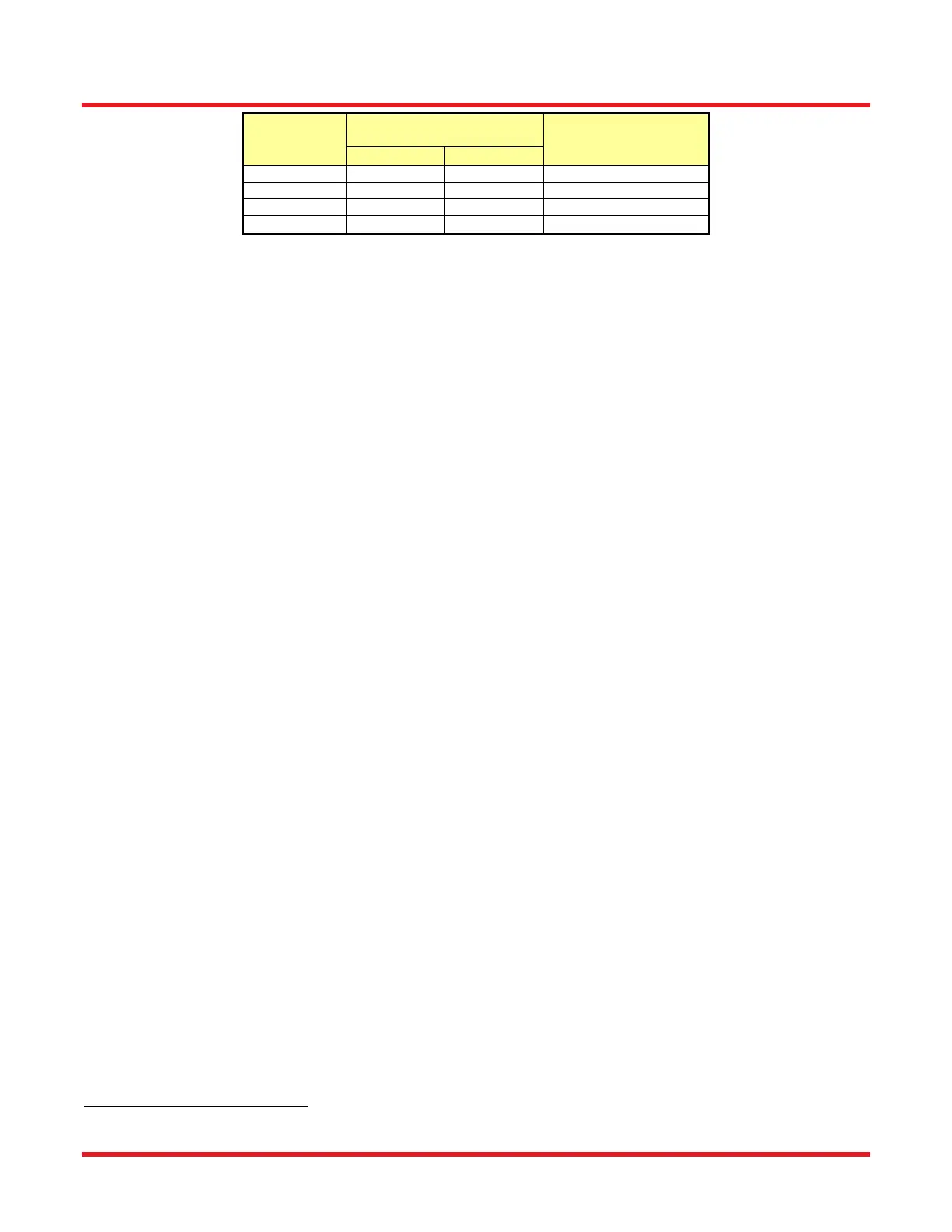

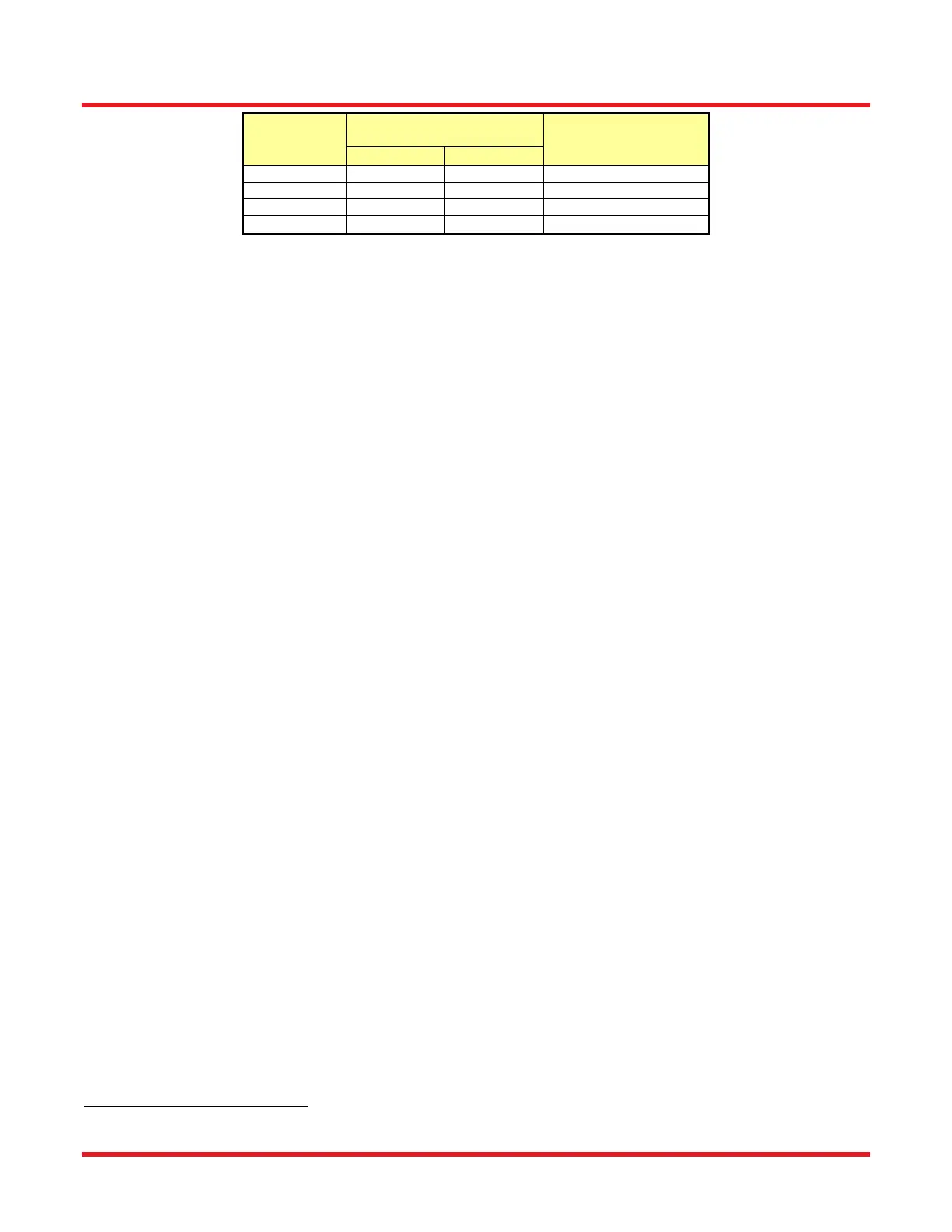

Item # Accepted Cladding

Diameter

1

Maximum Buffer

Diameter

End 1 End 2

CST080180

80 µm 80 µm 180 µm

CSTM080125

80 µm 125 µm 250 µm

CST125250

125 µm 125 µm 250 µm

CST125400

125 µm 125 µm 400 µm

For some coatings, the stripping force is unacceptably high even if the operating temperature of the TMS insert is

increased or reduced. For these coatings, either revert to traditional chemical stripping techniques, or

alternatively, employ the Soak method described above with an appropriate solvent prior to thermal stripping. This

will often soften the coating enough to strip effectively with TMS.

With the fiber loaded in the FHBs open the Cleave Lid of the Cleave Block and position the fiber in the groove to

the right of the stripper/cleaver block against the stripping stop. The internal vacuum will activate and draw the

fiber into the stripper V-groove. Make sure:

The cleave lever is in the forward position, pointing towards the user.

The fiber is properly seated in the V-groove of the bottom TMS.

The fiber does not protrude past the stripper blade.

Gently lower the Cleave Lid top to capture the coating. There are magnets built into the Cleave Block, and the Lid

‘gets heavier’ as it closer to the Closed position. Some users find it easier to place their thumb at the front of the

Cleave Block, to hold the lid very slightly open, so they can better control the closing force of the Lid. Repeatedly

closing the Cleave Lid heavily can cause damage to the Cleave Inserts.

It takes approximately five (5) seconds for the TMS blades to reach the appropriate temperature. During the heat

up period, the strip indicator/cleave button light will flash. The thermo-mechanical stripper is ready to be used

when the indicator stops flashing. The heating element will be maintained at the stripping temperature for a period

of time as defined in the TMS setup (usually 10 - 30 seconds). At this point, the indicator light will extinguish, and

the heating element will return to the background temperature. To reactivate the heating element, remove the

FHB from the stripping station (make sure the stripper/cleaver top is open first) and then reinsert. This will

reinitiate the thermo-mechanical stripping process.

When the heating element reaches the pre-set temperature (strip indicator/cleave button on, not flashing), the

fiber can be stripped. Slide the FHB away from the stripper/cleaver block. Use a smooth, even sliding action to

strip the coating to the proper length.

1

For different cladding diameters than those listed here, please contact Thorlabs Technical Support. TMS blade inserts are available for

cladding diameters up to Ø200 µm upon request.

Loading...

Loading...