FFS2000 Series Chapter 3: Description

Page 8 TTN047338-D02

Fiber Cleave Lever: The lever is used at the cleave station on the FPC200 Preparation Station (sold

separately) to apply tension to the fiber.

Alignment Pins: The alignment pins position the fiber holding block during the fiber handling at each

station.

Z-Axis Drive: The Z-axis drive positions the fiber in axial direction.

3.5.3. Rotary Fiber Holding Block for PM Alignment (Item #s FFS2000PM and FFS2000WS)

The fiber holding block (Item # FHBR1) consist of a U-shaped frame and a center, spring-loaded block that

contains a replaceable vacuum V-groove insert within a rotary mechanism. A magnetic top is used to clamp the

fiber in the V-groove as the FHB is moved from station to station.

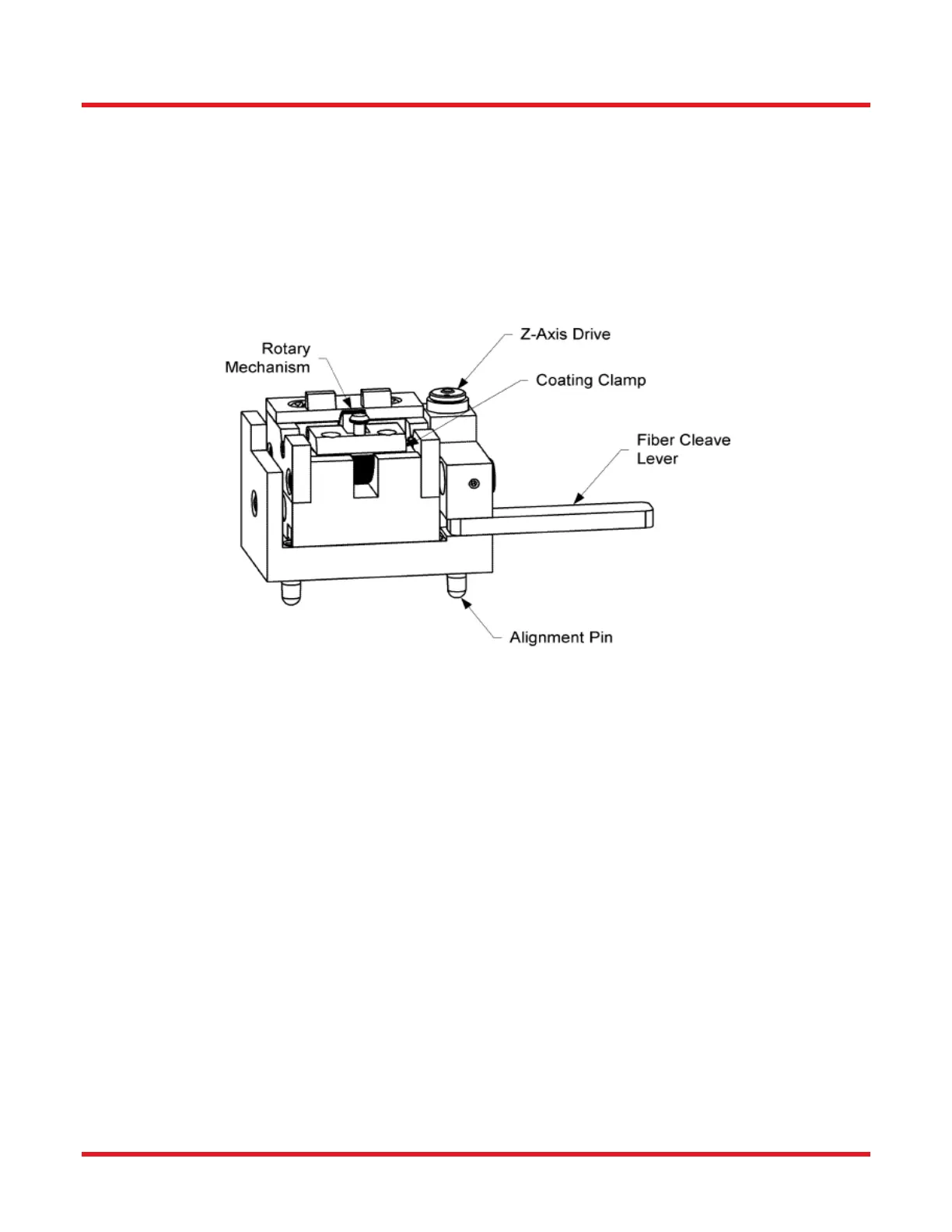

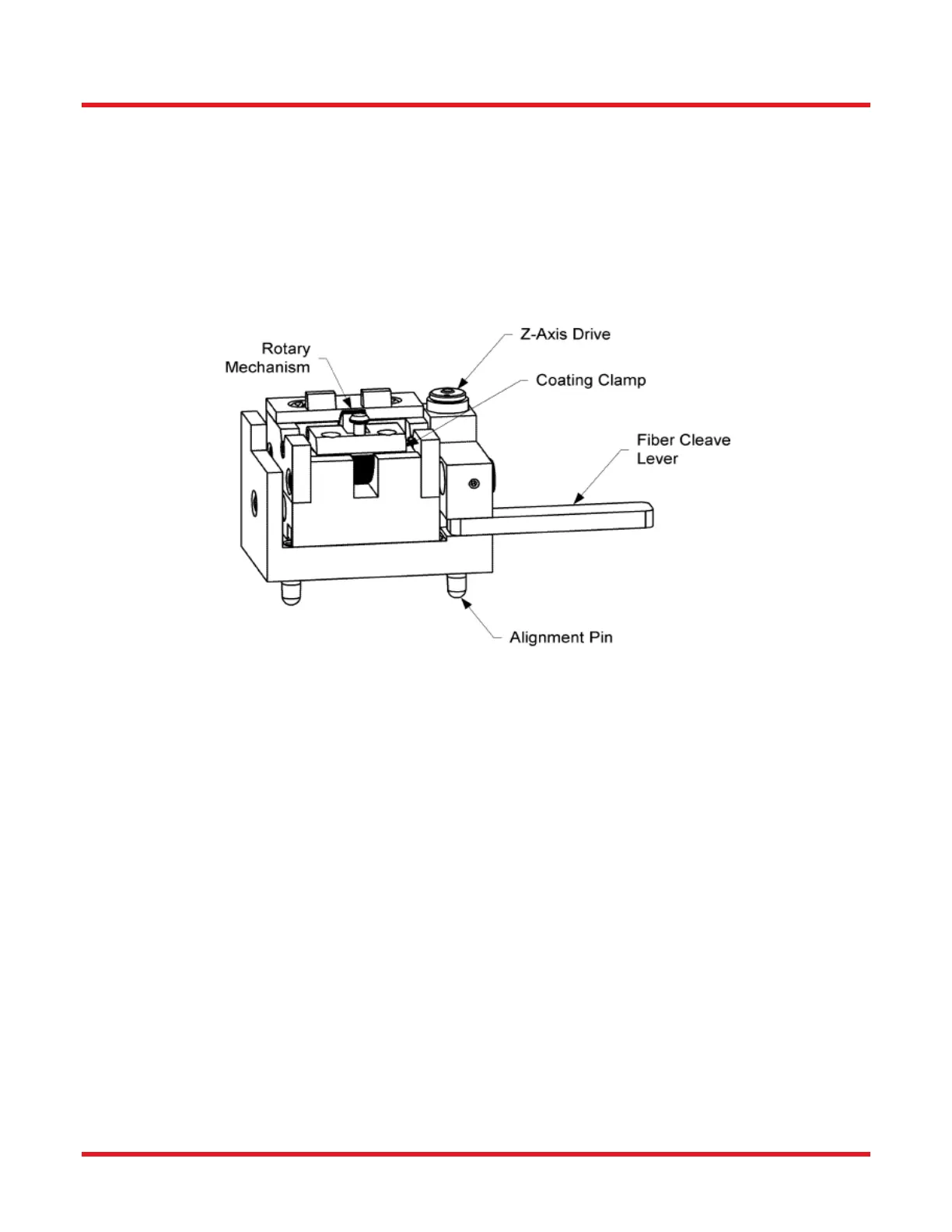

Figure 4 Rotary Fiber Holding Block

FHB V-Groove Insert: The V-Groove Insert captures the fiber securely and allows the fiber to be

transported within the fiber holding block between the stations. The bottom V-Groove inserts are

purchased separately; if purchased with an FFS2000PM base unit they will have been installed and

factory aligned. Various sizes are available to support a range of coating diameters; for details please see

Chapter 12 Specifications. Replacements can be purchased from www.thorlabs.com and can be

installed by the end user.

Fiber Cleave Lever: The lever is used at the FPC200 Fiber Preparation Station (Sold Separately) to

apply tension to the fiber.

Alignment Pins: The alignment pins position the fiber holding block during the fiber handling at each

station.

Z-Axis Drive: The Z-axis drive positions the fiber in axial direction.

Rotary Mechanism: The rotary mechanism is used to rotationally align the fiber with a resolution of

0.01°.

3.5.4. Soak Station

The soaking station is used to soften the acrylate polymer coating on the fiber so that it can be stripped off without

scratching or abrading the underlying glass surface. The coating is softened by immersing the fiber in a solvent

appropriate for the stripping method used. Presoaking will not be necessary for most fibers stripped using the

thermo mechanical method. The soaking station consists of left- and right-hand dunking jigs, solvent container,

and indicator lamps.

Loading...

Loading...