FFS2000 Series Chapter 3: Description

Rev B, July 21, 2017 Page 9

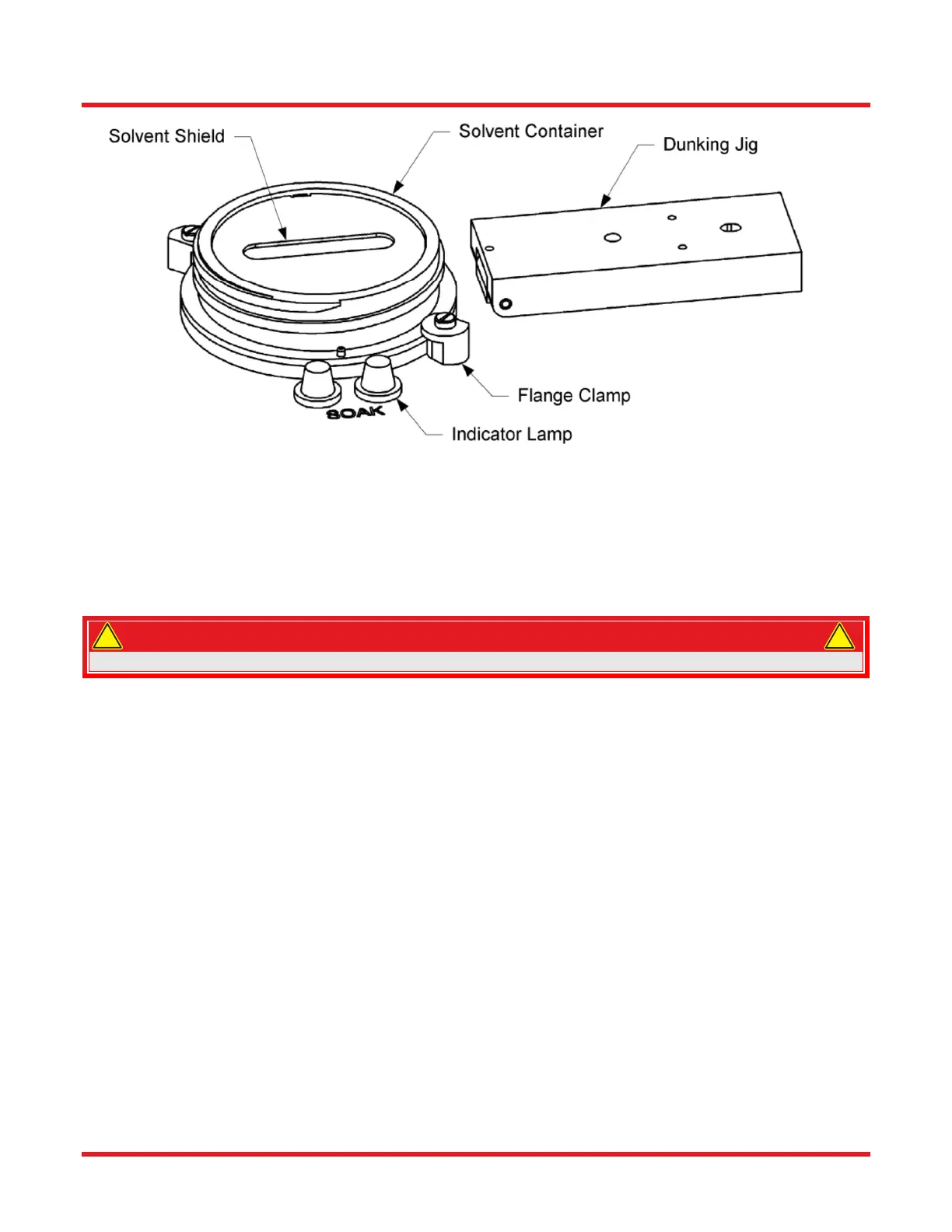

Figure 5 Soak Station

Dunking Jig: The dunking jig is used to mount the fiber holding blocks at the soaking station. Vacuum is

turned on when a FHB is inserted into the dunking jig in horizontal position. Vacuum turns off when

dunking jig is raised to immerse the fiber in the solvent (max. 90°).

Solvent Container: The solvent container holds the solvent which softens the acrylate coating on the

fiber. Solvent should be filled up to 1/8” of the top of the can.

WARNING

Read the MSDS Sheet for any chemical used in the soak station.

Solvent Shield: The solvent shield reduces splashing of the solvent during ultrasonic operation.

Indicator Lamp: The indicator lamps light up when the soaking time expires and stay lit until the dunking

jig is lowered.

Flange Clamp: The flange clamps hold the solvent container in place. Unscrew 1/2 turn to release the

container.

3.5.5. Strip and Cleave Station

This station serves the dual functions of stripping and cleaving. Two positions are provided for the FHBs: a slot

allowing it to slide during the stripping procedure and precision aligned bushings to hold it securely for the

cleaving procedure.

Strip Station

With the FHB in the stripping position, the acrylate fiber coating is captured by a matched set of stripper blades

and can be removed with a light sliding force.

!

!

Loading...

Loading...