FFS2000 Series Chapter 7: Splicing the Fiber

Rev B, July 21, 2017 Page 49

Lift the left side of the Transfer Jig first, then the right side. This allows the square end on the right side to

keep the Transfer Jig straight (so it does not rock towards the user or towards the back of the machine),

once the fiber is clear, then lift the RHS of the Transfer jig.

Proper Splice Optimization will avoid overheating the fiber during splicing. Overheating can be brought

about by use of an excessive splice power and/or splice time. This causes an increase in silica deposits

on the fiber, which can’t be completely removed during the fire polish step. The result will be decreased

splice strengths. Thorlabs personnel can advise on the correct methods of performing splices to avoid this

issue.

Use only Thorlabs supplied or recommended gas lines and regulators, and use the specified grade of

Argon purity. Other gas lines or regulators may contain contaminants, which could reduce splice strength.

The gas line should always be purged when the gas supply is turned on and/or whenever the gas line is

connected. Note: A low flow purge is always maintained even when the purge light is out or when the

system is shut off.

Exchange the Cleaning Solvent regularly, and wipe the Cleaning Can with clean tissue. In particular IPA

is hygroscopic and should be renewed every shift in production environments. Also take care to replace

the Vapor Shield over the Cleaning Can when not in use.

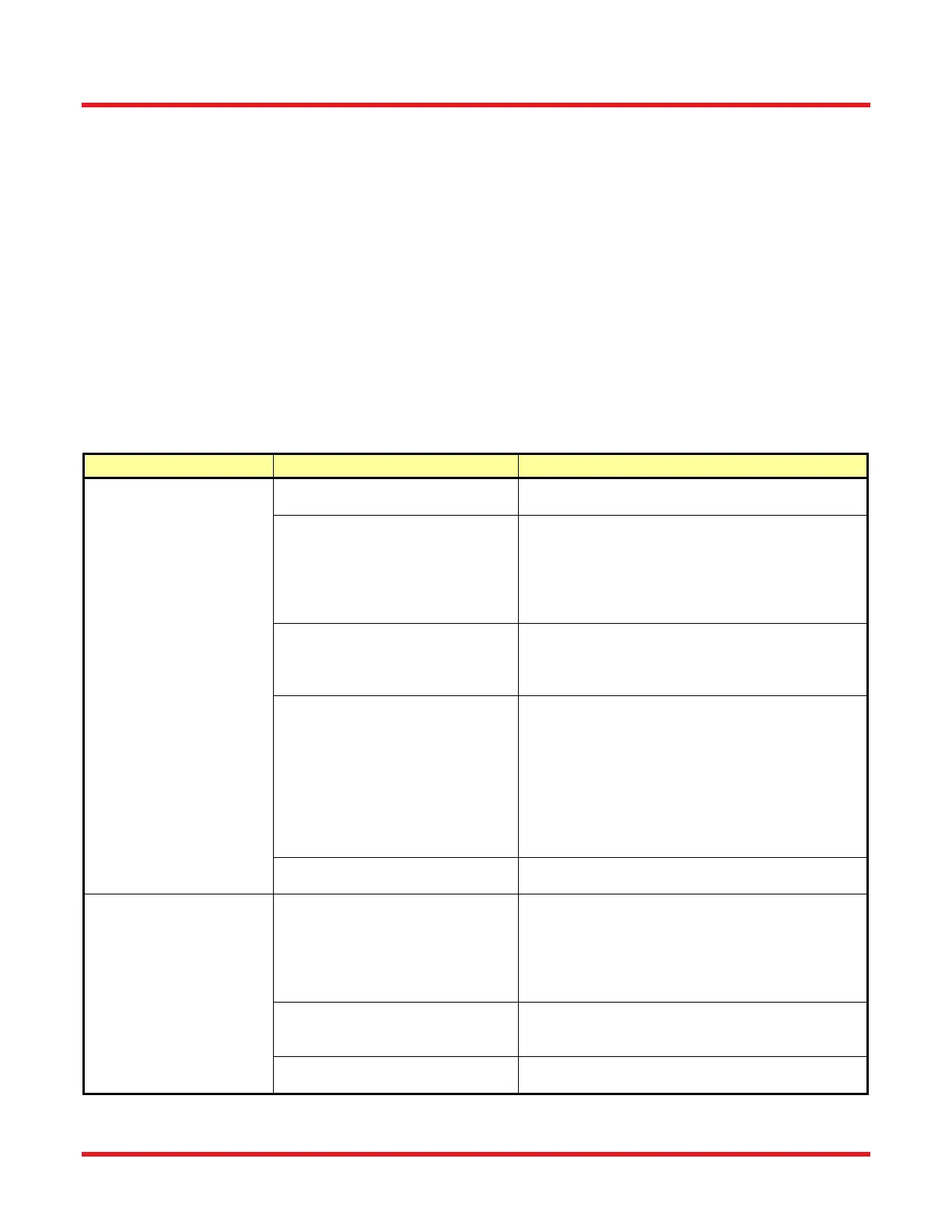

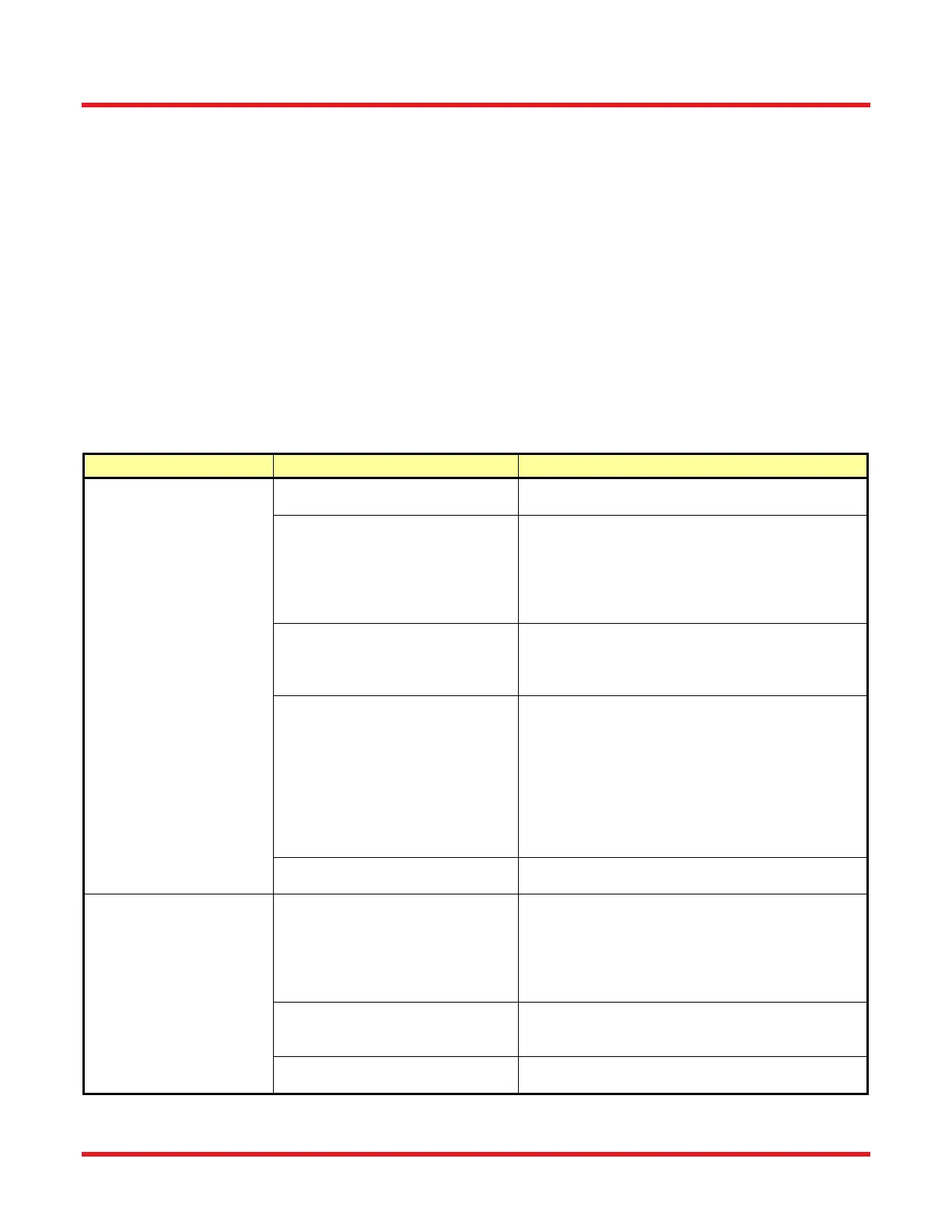

7.6. Diagnostics

Problem Possible Cause Solution

Fibers poorly

positioned on screen

Vacuum not present at v-

grooves.

Ensure vacuum is turned on and connected

properly.

Contamination present on fibers

or in graphite v-grooves.

In order to preserve splice strength use the

Load Fibers routine before removing the FHBs

from the splice station. Insert the contaminated

fiber into the cleaning station to remove excess

coating and debris. Use only the flat toothbrush

provided to clean the graphite v-grooves.

Contamination on Splice Head

surface or under Splice Cap.

Clean surfaces with a cotton swab moistened

with IPA. Take care not to brush dirt onto the

Lens Port or the mirrors. Check that the filament

is properly seated.

Fiber strip distance is too short

(Strip shoulder is unintentionally

within graphite).

Ensure that the FHB is pushed up to the Strip

Length Stops before closing the Cleave Lid. The

FHB lever should be in the forward position

when stripping, so on machines which are set

up for the very minimum strip length, neglecting

to position the lever correctly will result in the

coating hitting the edge of, or sitting within, the

Graphite v-grooves. Re-prepare the fiber in this

case.

Strip length stops are in a bad

position.

Move stops inward to increase Strip Length.

Pre-loss is high.

Coating particles adhering to

fiber prevent proper seating in

the positioner V-grooves.

In order to preserve splice strength use the

Load Fibers routine before removing the FHBs

from the splice station. Insert the contaminated

fiber into the cleaning station to remove excess

coating and debris. Use only the flat toothbrush

provided to clean the graphite v-grooves.

Background argon flow too high. Excessive argon flow above the standard 0.15

liters per minute may cause the left-hand fiber to

vibrate in the gas flow.

Very poor cleave with damage in

core region.

See the diagnostics section for the cleaving

process.

Loading...

Loading...