FFS2000 Series Chapter 7: Splicing the Fiber

Page 50 TTN047338-D02

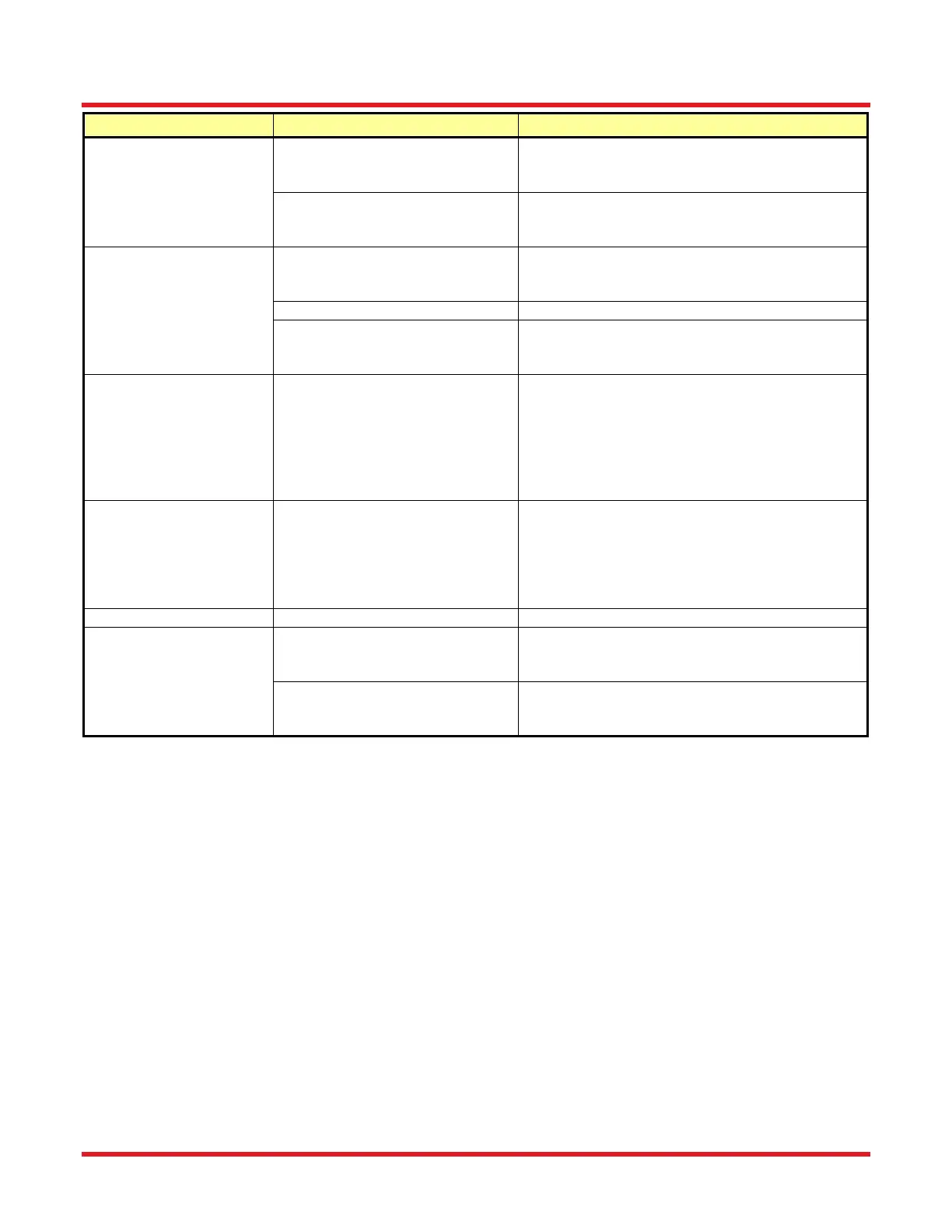

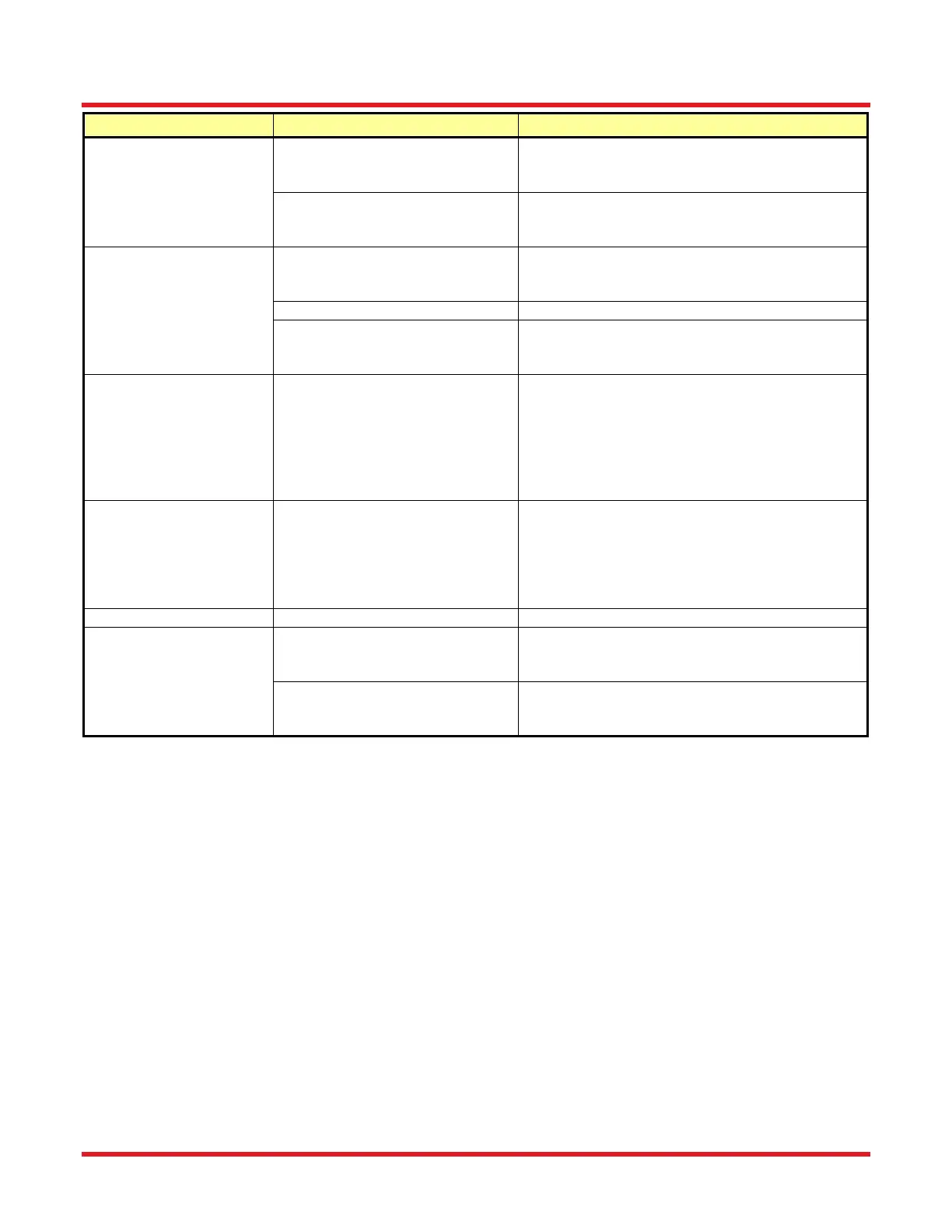

Problem Possible Cause Solution

Splice loss drops

instantly, then slowly

increases.

Filament power is too high. Run filament normalization. System will

automatically optimize power level and view-to-

splice distance.

Filament has aged. Run filament normalization. System will

automatically optimize power level and view-to-

splice distance.

Splice is not fully

fused, or loss does not

"bottom out".

Filament power is too low. Run filament normalization. System will

automatically optimize power level and view-to-

splice distance.

Splice time is too short. Increase the splice time in 0.5 s increments.

New filament installed without

carrying out filament

normalization.

Run filament normalization. System will

automatically optimize power level and view-to-

splice distance.

Bubble occurs at

splice.

Fiber ends did not meet properly

due to cleave defect.

Fiber ends did not meet properly

due to contamination on the fiber

ends.

Check the cleaver and adjust if necessary (refer

to Maintenance section for procedures).

Inspect fiber end for dirt/debris. Remove

dirt/debris by using the cleaning station or re-

cleave fiber. (Note: Clean cleaver blade with Q-

Tip and acetone prior to re-cleaving. See

Maintenance section.)

Neckdown occurs at

splice. (Fibers are

fused but the point of

the splice is narrower

than the normal fiber

diameter.)

Fiber ends were not touching

during the hot-push.

The right hand fiber did not push sufficiently

because the strip length was incorrect and the

shoulder of the primary coating butted the end

of the Graphite, or the fiber gap was incorrect

due to a poor cleave, or the FHB hit a software

or hardware limit.

Bulge occurs at splice.

Hot Push distance too high. Decrease the Hot Push distance.

Fiber ends bubble

apart in “q-tip” splice.

Fiber ends too far apart prior to

the Hot Push.

Increase the Pre-Push distance by 2 µm

increments, but do not exceed 16 µm total pre-

push.

Filament power is too high. Run filament normalization. System will

automatically optimize power level and view-to-

splice distance.

Loading...

Loading...