FFS2000 Series Chapter 6: Fiber Preparation

Rev B, July 21, 2017 Page 35

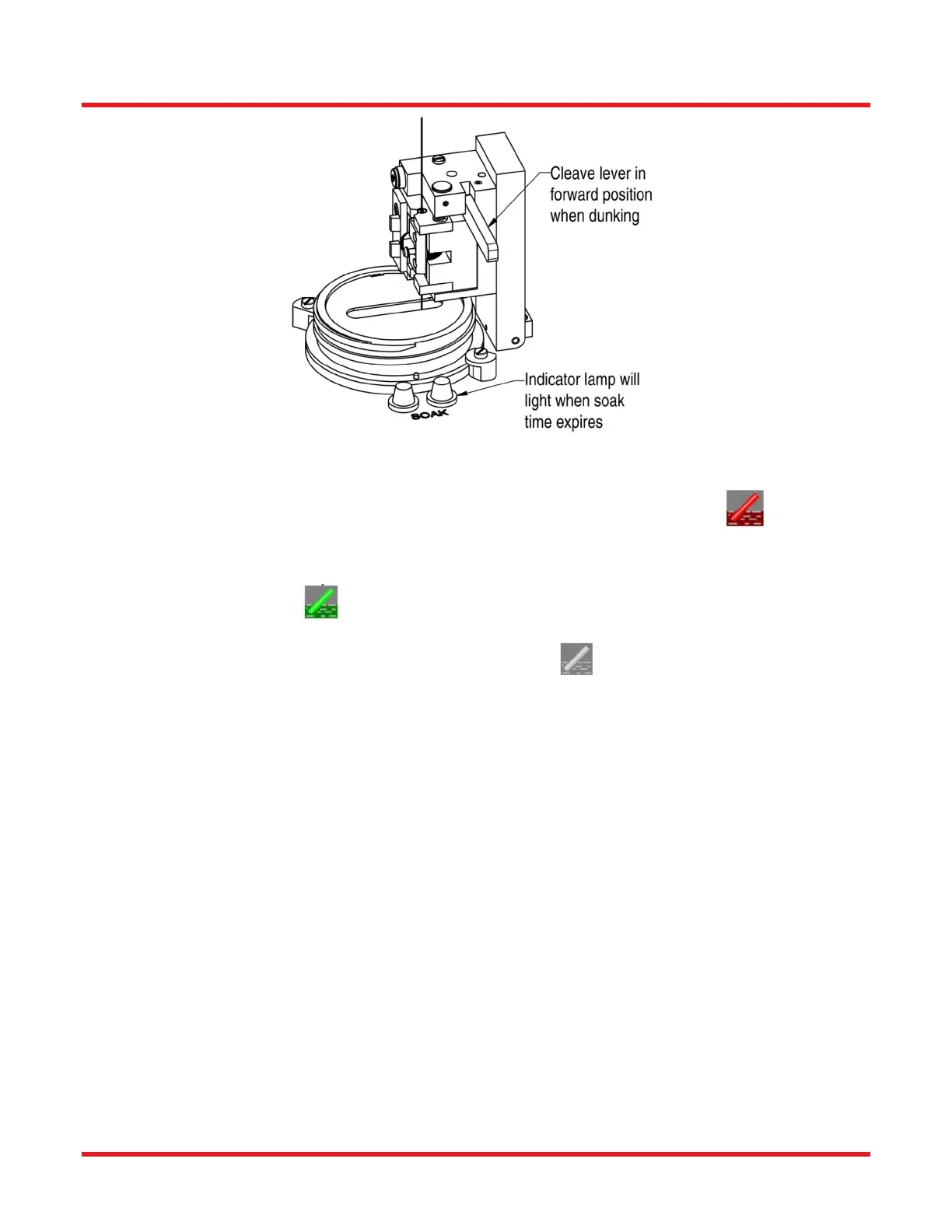

Figure 38 Soaking Procedure

Once the dunking jig has been raised the vacuum will shut off and the Soak Right Indicator of the GUI will

highlight red. The indicators will remain in this state for the preset soak time.

After the soak time has elapsed, the right soak indicator lamp on the splicer workstation will light red, and the

Soak Right Indicator of the GUI will highlight green.

When the dunking jig is lowered, the Soak Right Indicator of the GUI will cease to be highlighted and the red

indicator lamp of the splicer workstation will turn off.

Note: The quickest, most convenient way to remove the FHB from the dunking jig, when in the dunked position, is

to grab the FHB and allow the dunking jig to “fall” back into place. If the FHB and dunking jig are first lowered

back together, the vacuum will activate and make removal of the FHB more difficult.

6.2.3. Stripping Procedure

The Thermo-Mechanical Stripper (TMS) is incorporated into the Cleave Block assembly. The TMS consists of a

heated guide piece and a cover piece. Both parts have blades at either end that pinch the fiber coating. Sufficient

force is applied to the coating such that it may be removed cleanly from the fiber. The blades are manufactured to

close tolerances; if they are in any way damaged then it is likely that the cladding surface will be damaged as the

coating is removed. Damage to the stripper blades normally occurs when the fiber is not correctly positioned in

the V-groove guide or if a larger fiber cladding size is used than specified for the stripper blades in use.

The TMS is designed for use only on Acrylate coated fibers and options are available for purchase separately as

listed in the table below.

Loading...

Loading...