FFS2000 Series Chapter 6: Fiber Preparation

Page 34 TTN047338-D02

The thermo-mechanical stripping method uses heat to soften the acrylate coating. A heating element is

incorporated in the bottom V-groove insert at the stripping station. The heating element is kept at a low

background temperature at all times, which for some fibers (such as SMF-28) is sufficient to strip the coating

almost immediately. Other fibers require a high temperature “boost”, which rapidly increases the coating

temperature such that it can be stripped with minimal pull force. The boost time is typically less than 5 seconds.

Some fibers may also require a presoaking in acetone to soften the coating prior to thermo-mechanical stripping.

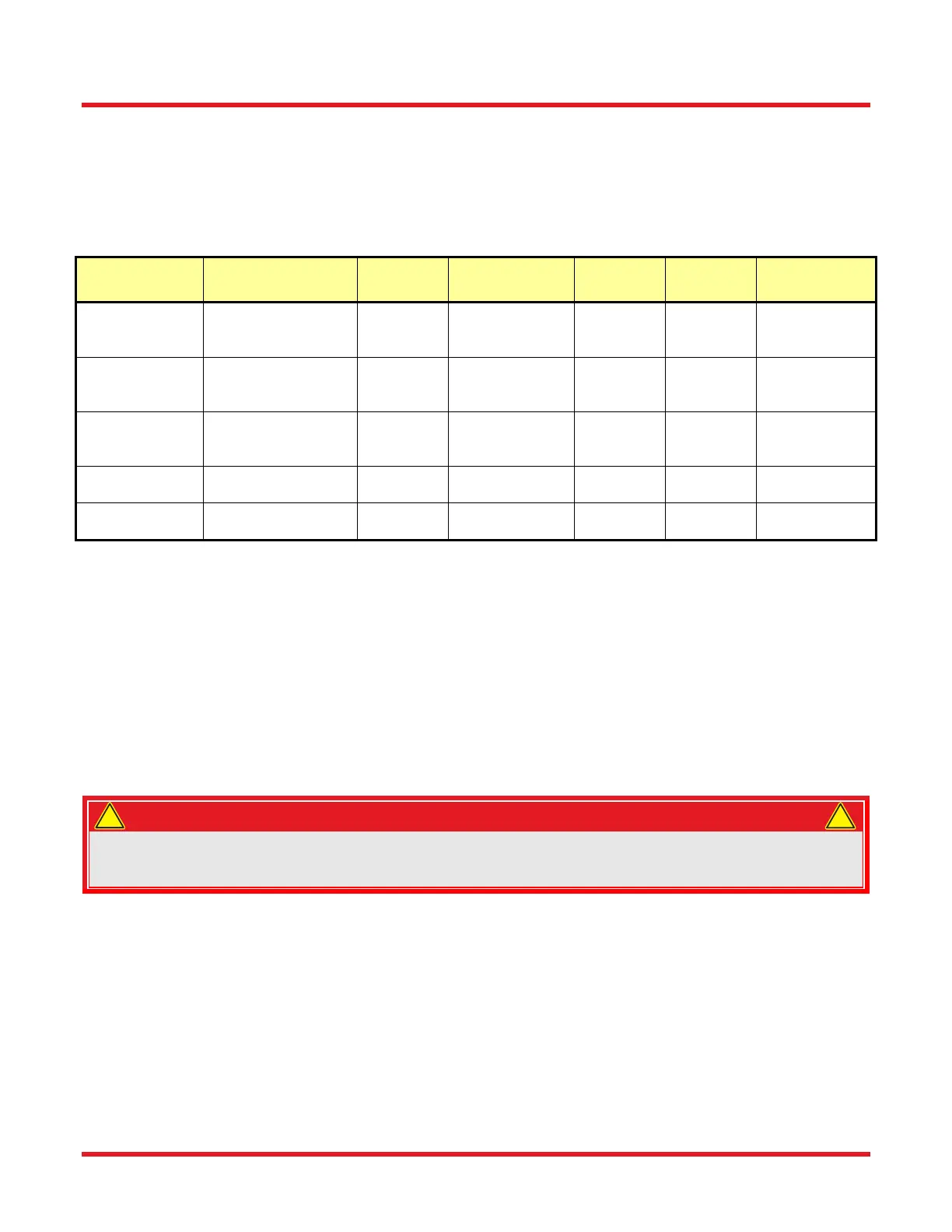

The recommended procedures for thermo-mechanically stripping various fiber types are shown in the table below.

Coating

Type

Fiber Type Heating

Time

Background

Current

Boost

Current

Pre-

Soak

Soak Time

& Solvent

Typical Dual

Coat Acrylate,

250 µm

Corning SMF-28 5 s 1500 mA 3500 mA No N/A

Typical Dual

Coat Acrylate,

250 µm

Corning CS-980

Flexcore 1060

5 s 1500 mA 3500 mA No N/A

250 µm and

165 µm

Acrylate

Fibercore Series

HB, HB-G, and HB-

T

10 s 1500 mA 3500 mA No N/A

250 µm

Acrylate

AT&T Erbium 0 - 5 s 1500 mA 3900 mA Yes 60 s in

acetone

250 µm

Acrylate

Most Other AT&T

Fiber

5 s 1500 mA 3900 mA No N/A

Soaking Station Preparation (Chemo-Mechanical Only)

Make sure the solvent is “topped up.” It should be approximately 1/8" to 1/4" below the lip of the solvent container.

Stripping Station Preparation

Clean the stripping station with the soft toothbrush (provided) or the optional vacuum cleaning system, keeping

your free hand as a ‘shield’ around the rear of the open Cleave Lid, to prevent debris being thrown up onto other

parts of the machine. Remove any stripped coating or other particles from the Cleave Inserts and around the

Stripper Blades. It is important that these surfaces are kept clean, or subsequent Strip or Cleave operations may

be less effective until these surfaces are cleaned.

WARNING

Do NOT clean the V-groove insert with solvent when the vacuum is turned on. The solvent will be

drawn into the vacuum system and will cause internal damage. If the V-Groove appears to be

damaged, replace the inserts.

6.2.2. Soaking Procedure (Chemo-Mechanical Only)

Place the right FHB with the preloaded fiber on the right side dunking jig at the soaking station. Inserting the FHB

pins into the dunking jig will activate the internal vacuum to the FHB V-groove. With the fiber secured in the FHB,

tilt the end of the dunking jig to immerse the fiber into the soaking station. Make sure that the FHB Cleave Lever is

in the forward (down) position to immerse the fiber deeper into the solvent, as shown in Figure 38.

!

!

Loading...

Loading...