FFS2000 Series Chapter 6: Fiber Preparation

Rev B, July 21, 2017 Page 39

Problem Possible Cause Solution

Heating time too long. If the fiber is pre-soaked, a long heating time may

dry out the soft buffer making it difficult to remove.

To avoid this the fiber should be stripped as soon

as possible after the heating element reaches the

proper temperature (indicator on steadily) or the

Boost Current should be reduced.

6.3. Cleaning the Fiber

The fiber is cleaned at the ultrasonic cleaning station. This removes any coating particles or residue left on the

glass surface that may reduce splice strength.

6.3.1. Setting Up

The appropriate parameters are stored in the Splice File and may be accessed in the fiber Preparation Menu in

the GUI.

Fiber Preparation Parameters

Check the parameters of the “Clean Time” and adjust as needed. Typical values range from 20 to 180 seconds,

depending upon solvent and inner coating composition. 30 seconds is a good starting clean time.

Note that parameter changes in the GUI are not saved into the Splice File (*.xml) until a file save is executed.

Cleaning Station Preparation

Make sure the cleaning solvent is “topped up.” It should be approximately 1/8" to 1/4" below the lip of the solvent

container.

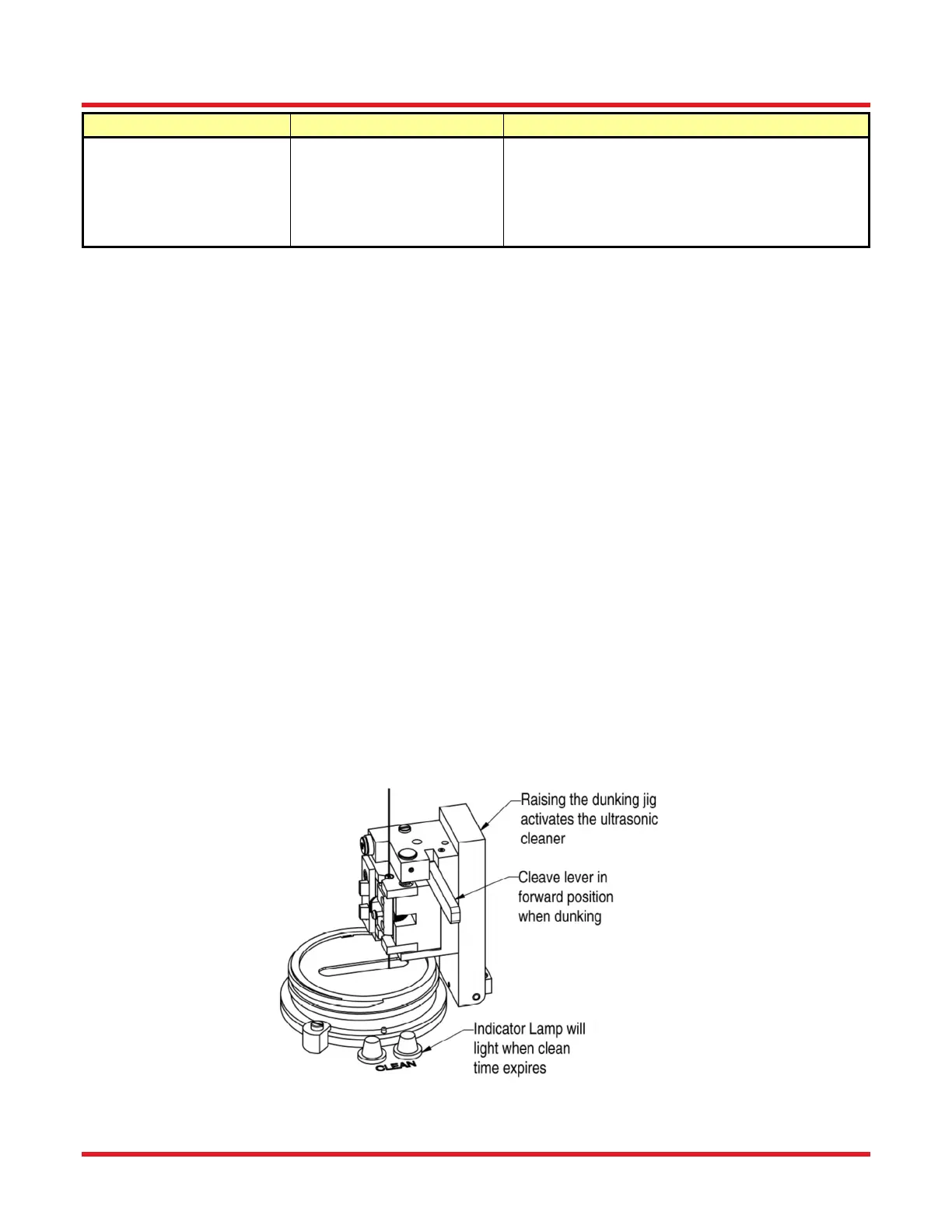

6.3.2. Cleaning Procedure

Place the right FHB with the preloaded fiber on the right side dunking jig at the cleaning station. Inserting the FHB

locating posts into the dunking jig will activate the internal vacuum to the FHB V-groove. With the fiber secured in

the FHB, tilt the end of the dunking jig to immerse the fiber into the cleaning station.

Figure 40 Cleaning Procedure

Loading...

Loading...