FFS2000 Series Chapter 7: Splicing the Fiber

Page 44 TTN047338-D02

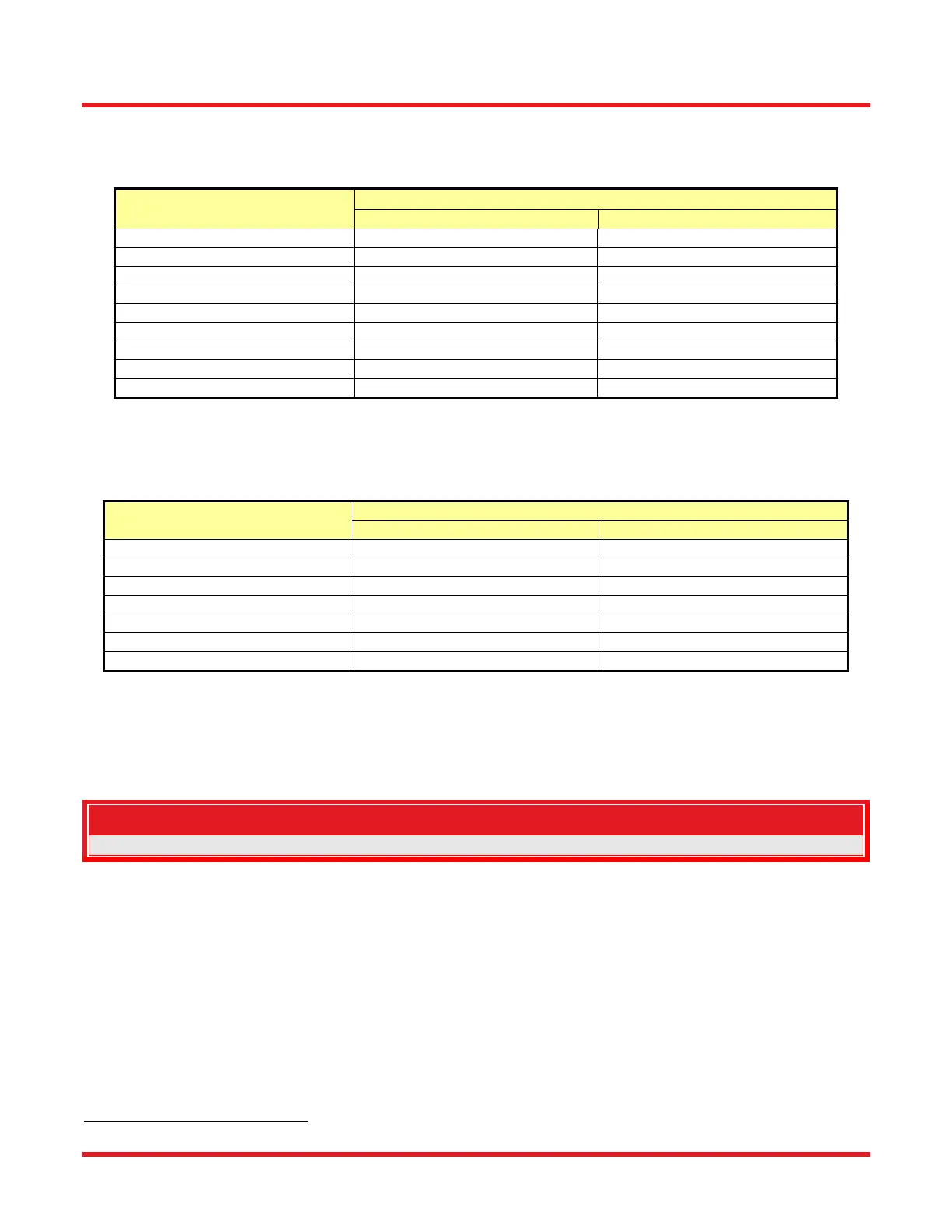

7.2.1. Splice Settings

Splice Parameters: Check the parameters of the ‘Splice Parameters’ in the ‘Splice’ menu of the GUI

under Splice Parameters. Refer to the table below for typical values.

Parameter Fiber Diameter

80 µm 125 µm

Pre-Gap

8 µm 8 µm

Pre-Push

5 µm 5 µm

Hot Push

10 – 14 µm 10 – 14 µm

Push Vel

88 µm/s 88 µm/s

Hot Push Delay

0.35 s 0.35 s

Argon

0.5 L/min 0.65 L/min

Splice Offset

0 µm 0 µm

On-Duration

1 – 5 s 1 – 5 s

Power

15.0 – 17.5 W 18.0 – 23.0 W

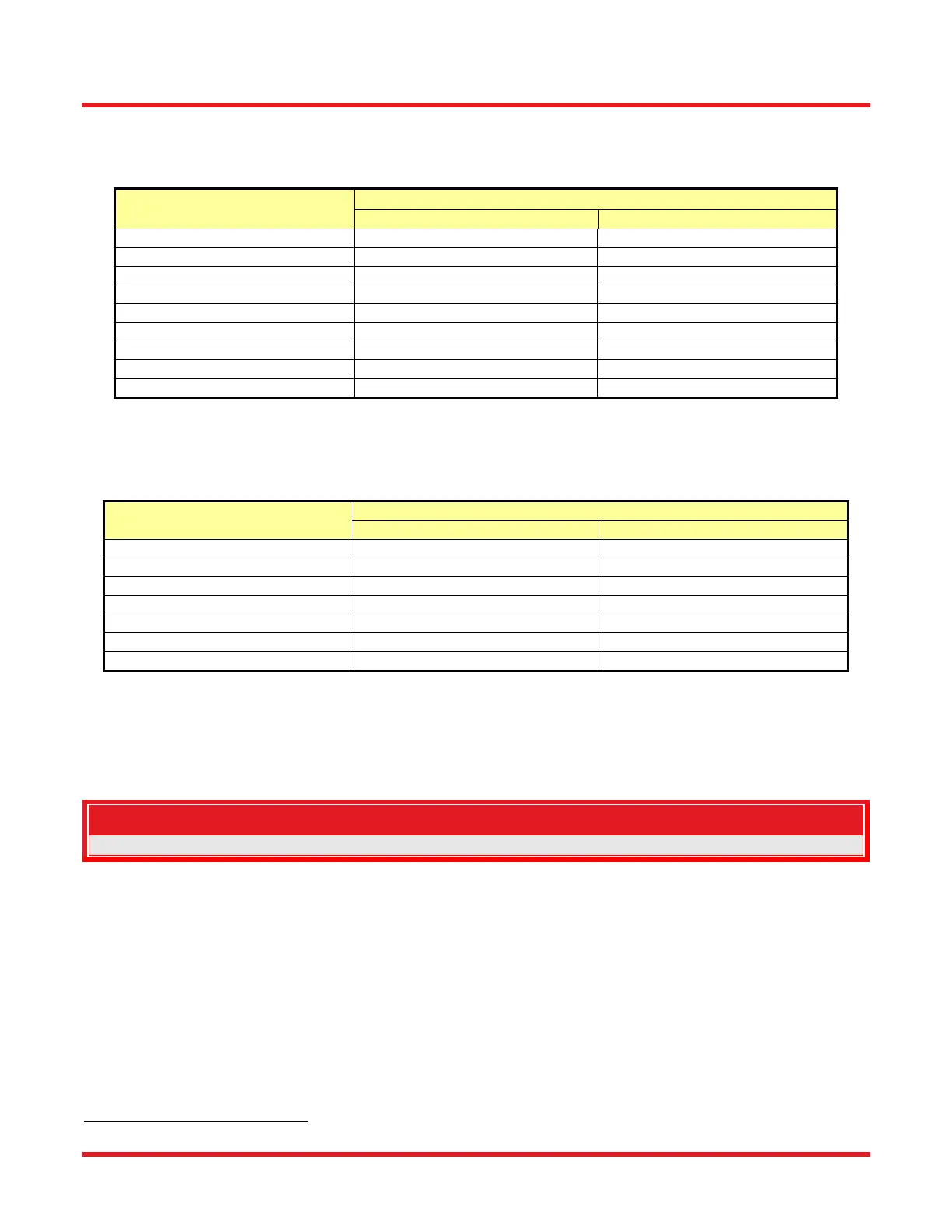

Fire Polish Parameters can be found in the ‘Splice’ menu of the GUI, under Splice Parameters > Fire

Polish. If the power is set to ZERO then the Fire Polish is OFF. Refer to the table below for typical

values.

Parameter Fiber Diameter

80μm 125μm

Delta

2

300 µm 300 µm

Passes

2

1 - 3 1 - 3

Velocity

2000 µm/s 2000 µm/s

Cool Threshold

60 s 60 s

Cool Duration

90 s 90 s

Argon

0.5 L/min 0.65 – 2.0 L/min

Power (same as splice power)

15.0 – 17.5 W 20.0 – 23.0 W

Tack Parameters: The Tack option should be selected only for splicing specialty fiber. To access the tack

parameters, select the ‘Tack Parameters’ in the ‘Splice’ menu of the software interface. The settings in

the tack dialog are the same as those in the splice dialog. If the tack power is set above zero then a tack

will be performed before the splice process.

Note

In most instances the tack power is set approximately 1 watt lower than the splice power.

PM Alignment Settings: Check the parameters of the ‘PM Alignment’ in the ‘Splice’ menu of the software

interface. Load the correct splice file corresponding to the fiber to be spliced.

7.3. Splicing and Fire Polishing Procedure

7.3.1. Preparing the Splice Station

Place the Transfer Jig over the Splice Station into the grooves of the bushings as shown in Figure 43. Do not

place the pins into the holes of the bushings. The Transfer Jig is thereby slightly elevated over the top plate of the

splicing workstation.

2

Delta x Passes ≤ 1000

Loading...

Loading...