FFS2000 Series Chapter 9: Proof Test (Item #s FFS2000PT and FFS2000WS)

Rev B, July 21, 2017 Page 59

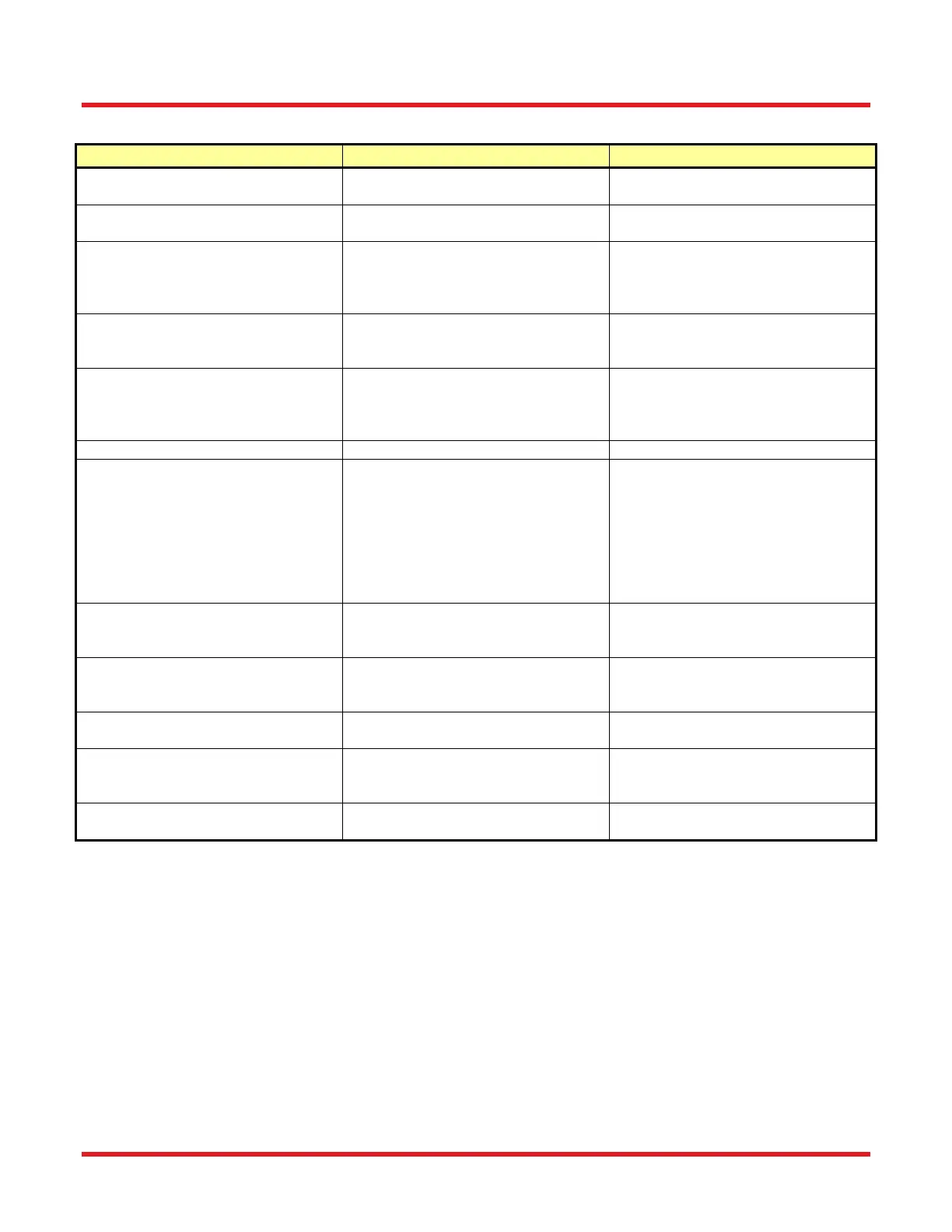

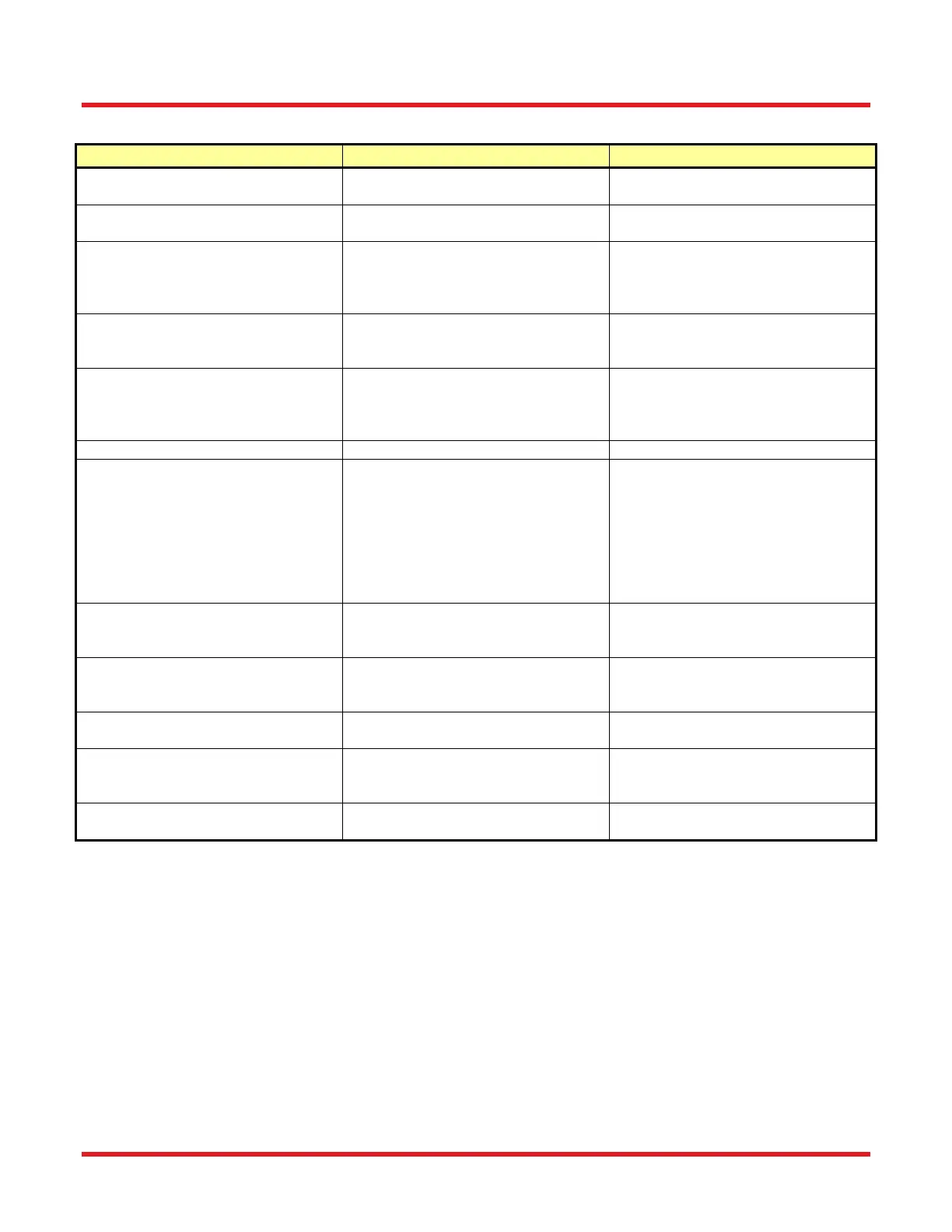

9.3. Diagnostics

Problem Possible Cause Solution

Fiber Slips at very high tension

levels.

Proof test grips are dirty. Clean proof test grips with a cotton

swab dipped in alcohol.

Proof test grips are work out. Contact Thorlabs to order

replacements.

An additional fiber wrap around the

mandrel may be required.

When proof testing at high tension

levels, the fiber should be wrapped

twice around the proof test grips to

prevent slippage.

Proof test clamps are rubbing

against the rubber grips, preventing

the clamps from gripping the fiber.

Reposition the rubber grips to clear

the clamps.

Tension levels seem

extraordinarily high or low for the

particular fiber being tested.

Wrong fiber diameter entered. The fiber diameter is used in the

tension level calculation. Check the

current fiber diameter. If it is

incorrect, re-enter the fiber diameter

Wrong peak tension level set. Correct the peak tension level.

Splice breaks consistently 3/16"

to the left of the splice point.

Left fiber scraped against the

filament when placing or removing

the FHB at the splicing station.

Carefully place and remove the

FHBs from the splicing station.

Scraping the bare fiber against the

tungsten filament seriously

degrades the strength of the fiber.

Using the load fibers routine when

placing the fibers into the splice

head will ensure careful placement.

Fiber breaks at the strip point.

Stripper blades are out of

alignment.

Realign the stripper blades (refer to

the Maintenance section for

procedures).

Fiber breaks at the fusion point

with dark deposits on either side

of the splice

The fire polish process was not

selected.

Ensure that the fire polish is set to

on.

The fire polish power was set too

low.

Increase the fire polish power to the

same level as the splice power.

The gas flow rate was too low

during the fire polish.

Check that the argon gas flow is set

to the same value as for the splice

(0.5 – 0.65 l/min).

The argon gas supply is not of

sufficient purity

Refer to Section 3.2.1 for gas

supply specifications.

Loading...

Loading...