FFS2000 Series Chapter 7: Splicing the Fiber

Page 48 TTN047338-D02

increase to splice levels for about 3 seconds to clean the system of any impurities and purge the Splice Head of

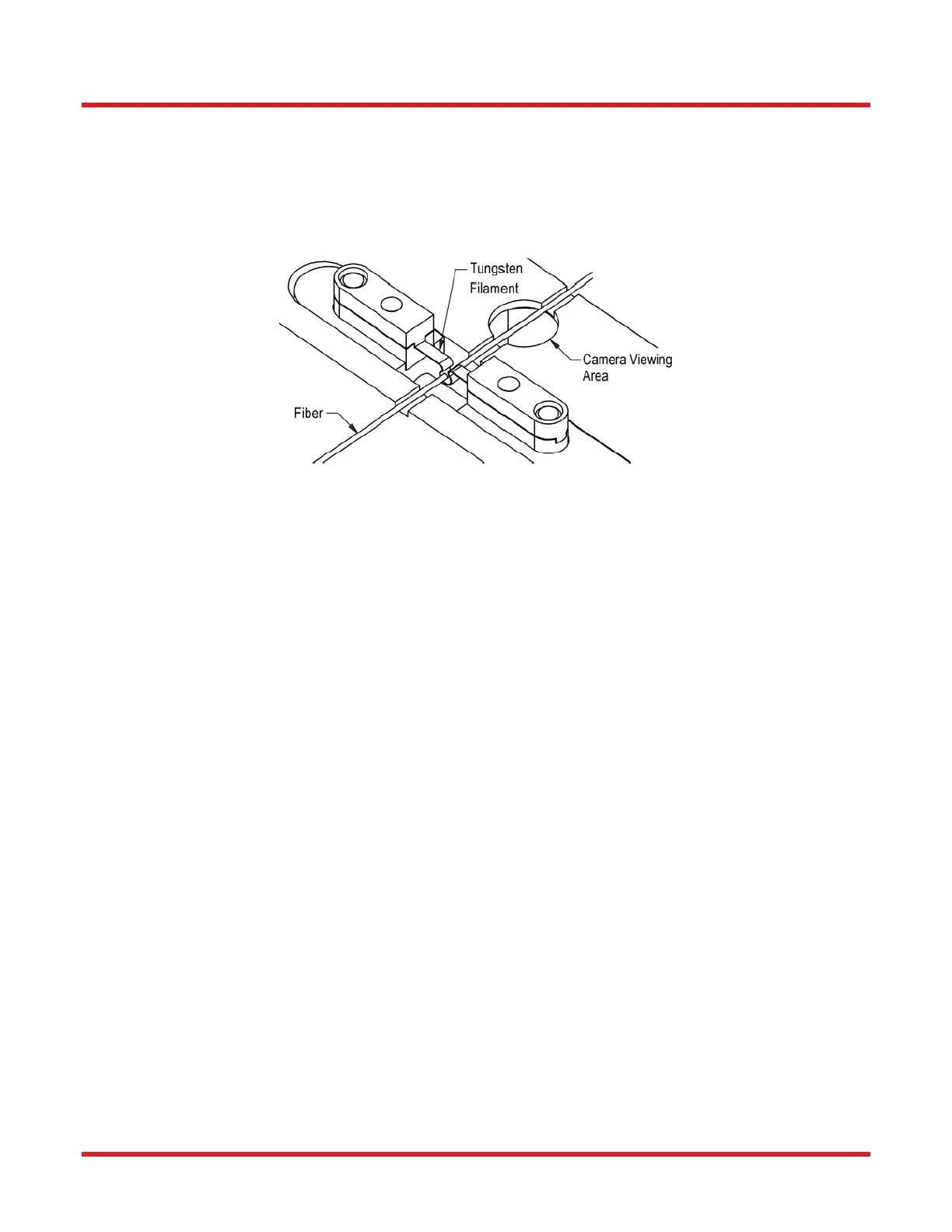

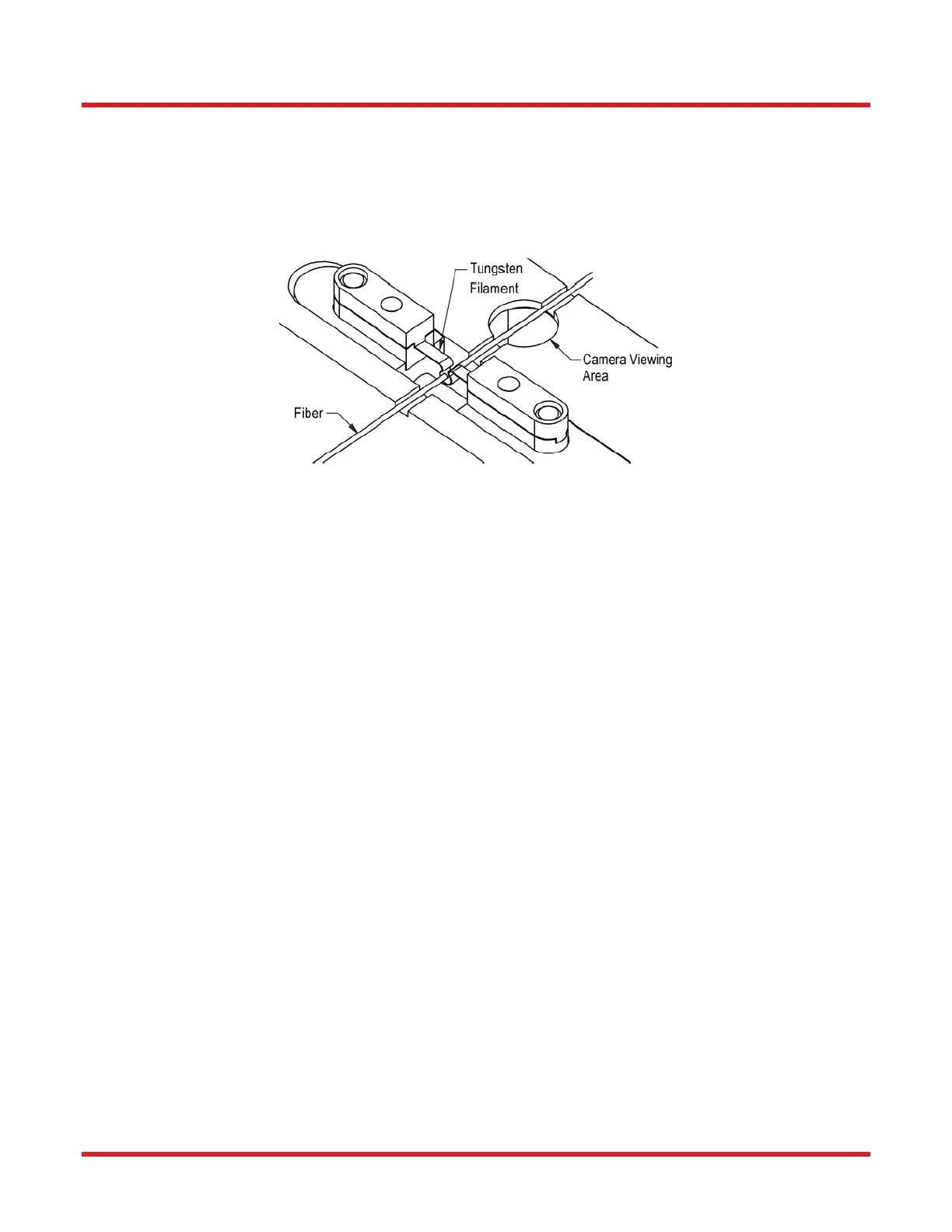

remaining oxygen. The Splice Head will then move the View To Splice Distance so that the filament is centered

on the fibers (assuming no Splice Offset is set). The filament is turned on and allowed to heat up for the user-

specified amount of time (Hot Push Delay) before the right-side fiber is pushed the distance defined as Hot Push,

bringing the fibers together. This allows any discontinuities in the edges of the fibers to "round-over", and also

increases the plasticity of the glass. The hot-push method of splicing results in a smoother splice and ensures

precise alignment.

Figure 47 Filament in Splice Position

Fire Polish

If Fire Polish is not activated (Fire Polish Power is set to zero), the Filament will turn off after the preset splice time

(On Duration) has elapsed. If Fire Polish was selected, the Filament remains on and the Splice Head will traverse

back and forth cleaning the Splice Region.

Splice Complete

After the Splicing and Fire Polishing processes are complete, the Filament shuts off, the Argon returns to

background levels, and the Splice Head returns to the view position (with the splice centered in the CCD camera

viewing area).

The spliced fibers are displayed in the Side View image (Back or Front View). When an Automatic One Button

Splice is completed, a small amount of tension is put on the fiber, which helps when removing the Transfer Jig to

avoid touching the Filament with the completed Splice. The amount of tension placed on the fiber can be specified

by selecting SpliceSet-UpPost Splice Tension… from the menu bar.

7.5. Guidelines for Achieving a High Strength Splice

The following guidelines are helpful in achieving a high-strength splice:

Splice strength will be seriously decreased by any abrasion to the glass surface. Care should be taken

not to touch the stripped portion of the fiber with fingers or try to wipe the bare fiber with a cloth or brush.

If small pieces of coating remain on the glass surface after stripping, do not try to restrip the coating. If the

coating pieces cannot be removed by ultrasonic cleaning or by a quick “dunk” in a soaking solvent, break

off the section of bare fiber and then prepare the fiber again

When positioning the fiber at the splice station, it is important not to knock or rub the fiber against any

surfaces except the vacuum graphite V-grooves.

Always perform a Load Fibers operation when loading the fibers into the splice station and, if it is

necessary, to remove unspliced fibers from the Splice Position.

Do not lift the FHB lid (which acts as the coating clamp) before removal of the Transfer Jig from the

splicing station. After the fiber is spliced, a slight tension is placed on the fiber to minimize the chance of

abrading the fiber during removal. If the FHB coating clamps are opened, the tension will be released.

Loading...

Loading...