FFS2000 Series Chapter 8: Recoat

Rev B, July 21, 2017 Page 55

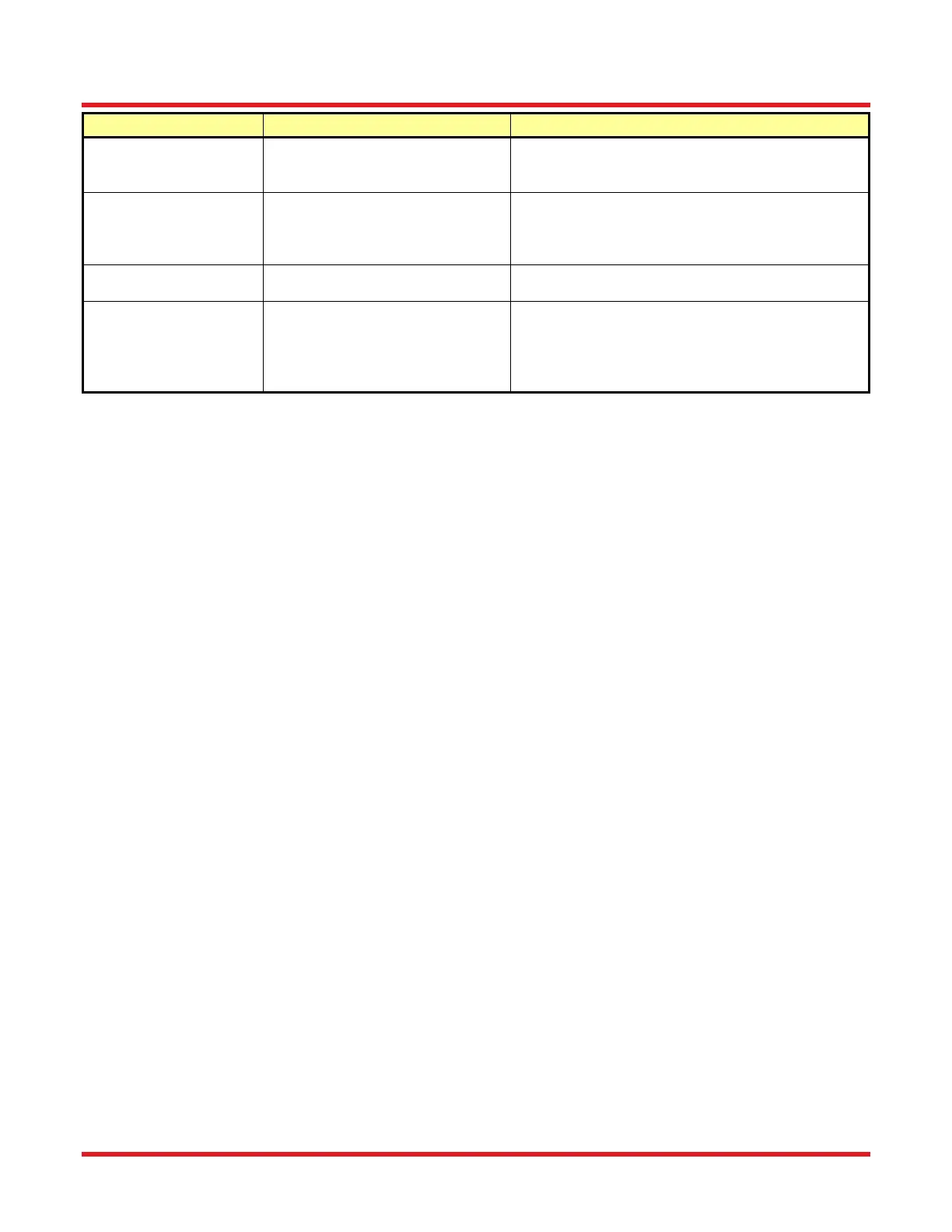

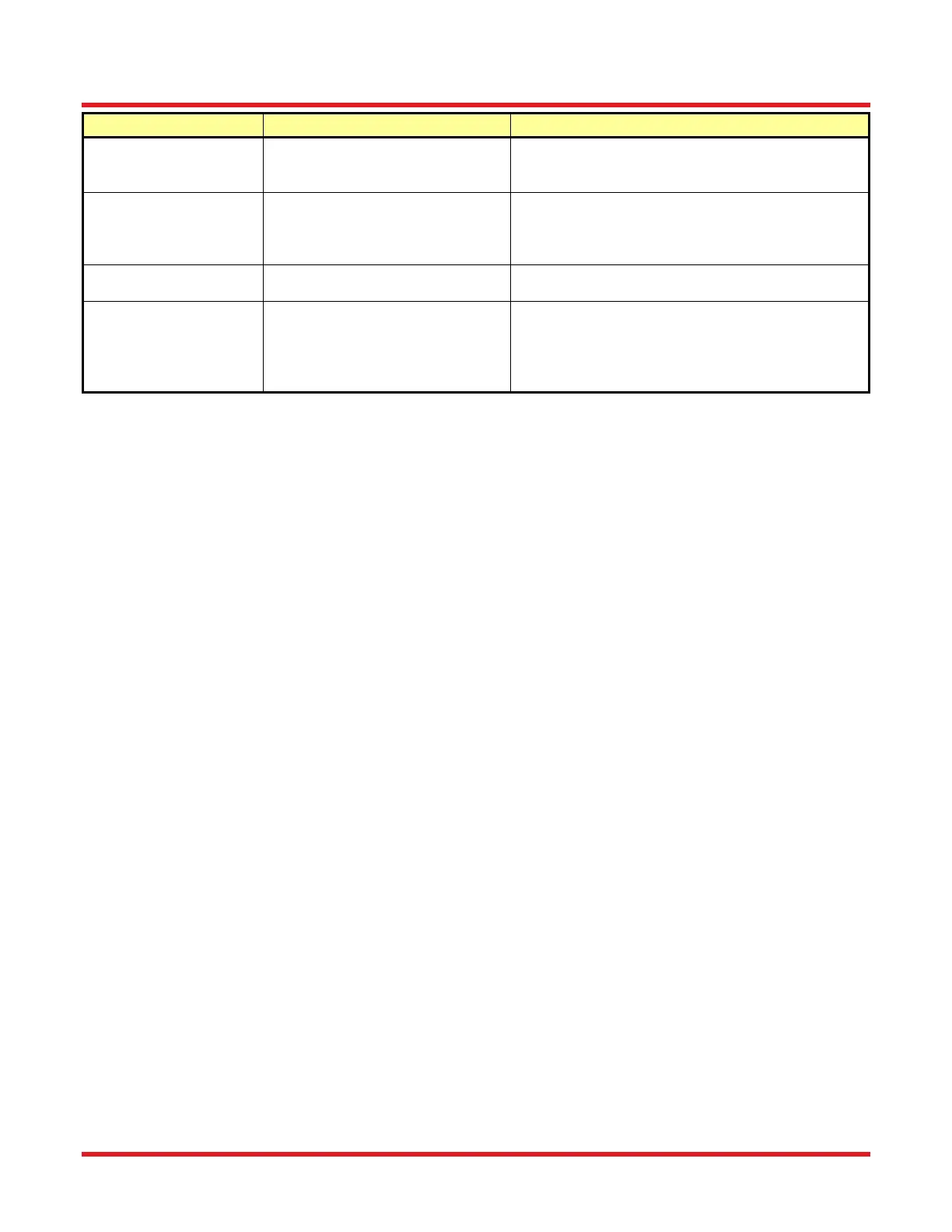

Problem Possible Cause Solution

Remote injector system leaking A leak in the remote injector system will allow air

to enter causing bubbles. Refill the tubing and

check that it will withstand a moderate pull.

Recoat top does not

lift easily or recoated

section adheres

tightly to mold plate.

Recoated fiber is adhering to

recoat plate and/or top.

It may be necessary to coat the mold plates with

a release agent prior to recoating. Contact

Thorlabs for release agent recommendations and

instructions for use.

Fiber sticks to recoat

mold consistently.

Recoat mold plates are dirty. The recoat mold plates should be cleaned as

described in Section 8.2.

Fiber snaps when

lifting the recoat mold

top.

Failed to first release the FHB

tops before lifting the recoat mold

top.

If the recoat mold top is lifted with the FHB tops

closed, the fiber may stick to the recoat mold top

and snap or degrade the strength of the fiber.

Always open the FHBs before lifting the recoat

mold top.

Loading...

Loading...