FFS2000 Series Chapter 6: Fiber Preparation

Page 42 TTN047338-D02

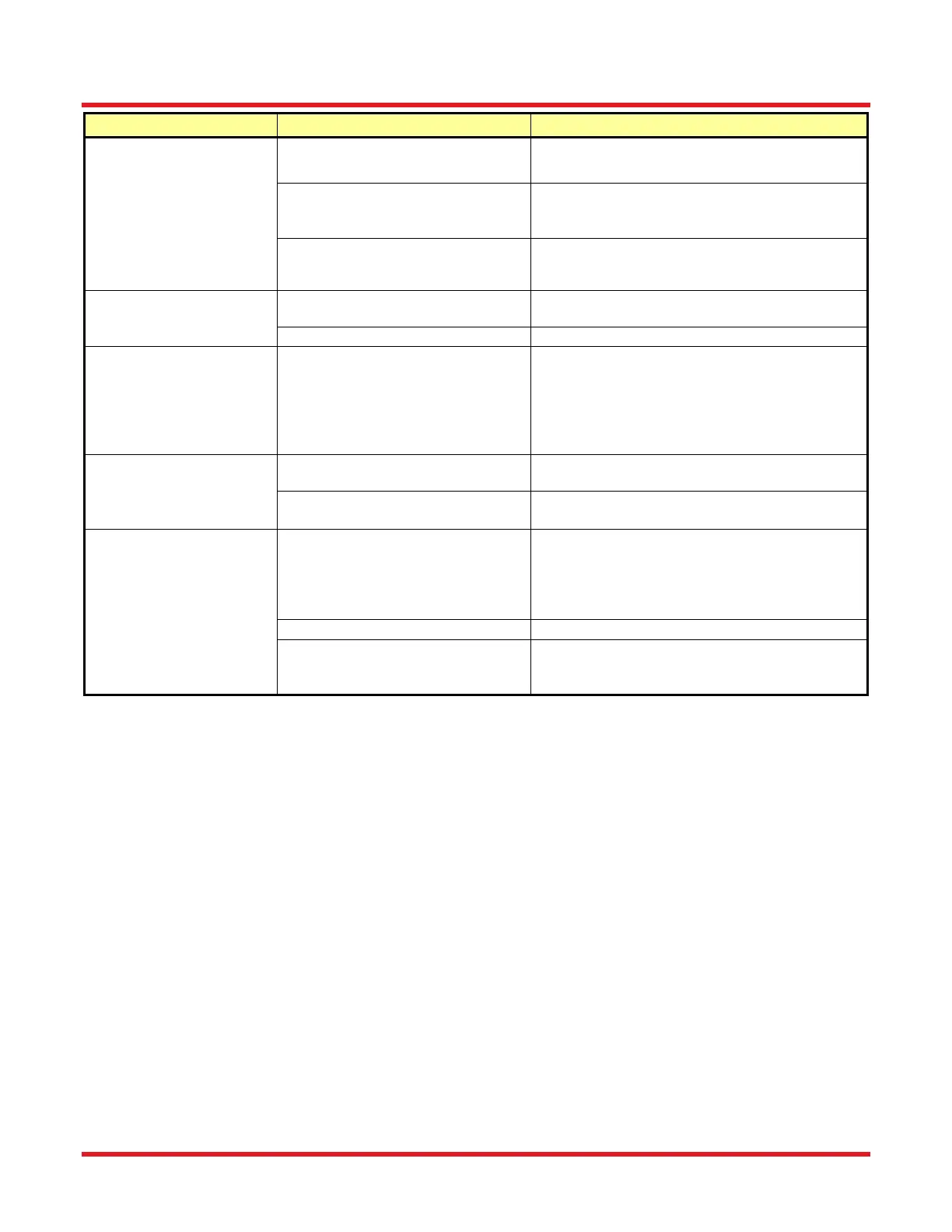

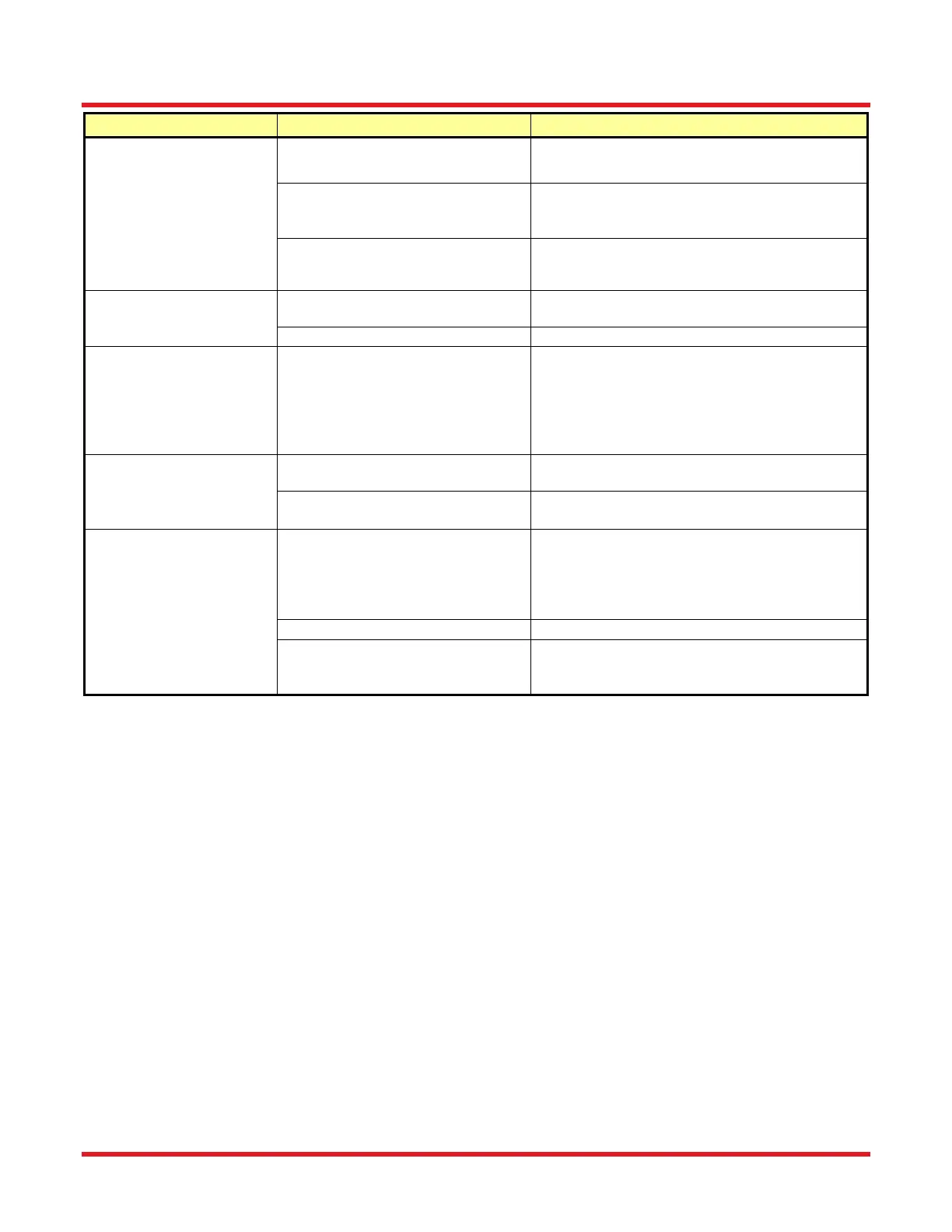

Problem Possible Cause Solution

Cleave blade is dirty. Clean the cleave blade with a cotton swab

dipped in isopropanol.

Cleave tension is insufficient

(check for FHB slippage; see

above).

Increase the cleave tension.

Cleave blade height adjustment

may be required

Please contact Thorlabs for instructions.

The FHB cocks forward

when the cleave lever

is released.

The bottom of the FHB or the

plate where the FHB sits is dirty.

Scrub with toothbrush provided.

Cleave tension is too high. Reduce cleave tension.

Fiber slips through or

breaks in the V-groove.

Stripper/cleaver top or V-grooves

are dirty, or FHB V-grooves are

dirty.

Clean the top and V-grooves using the soft

brush or a cotton swab dipped in isopropanol.

Note: If the fiber breaks in the stripper/cleaver

block and enough fiber remains in the V-

groove, remove the broken piece and re-

cleave.

Blade doesn’t touch

one or both fibers.

Fiber not in V-groove. Ensure fiber is correctly located in the V-

groove.

Cleave blade height adjustment

may be required.

Please contact Thorlabs for instructions.

Bad cleave.

FHB not sliding Freely. The FHBs must move smoothly and freely for

the correct tension to be applied to the fiber. If

the FHBs have become contaminated it may

be necessary to strip down and rebuild them.

Please contact Thorlabs for assistance.

Cleave tension needs adjustment. Adjust the cleave tension.

Cleave blade may be damaged. Inspect blade for chips/cracks. See the

Maintenance Section for instructions to rotate

the blade 180° to expose a new blade edge.

Loading...

Loading...