Tracker and SAS Placement

Topcon Paver System Five Operator’s Manual

6-10

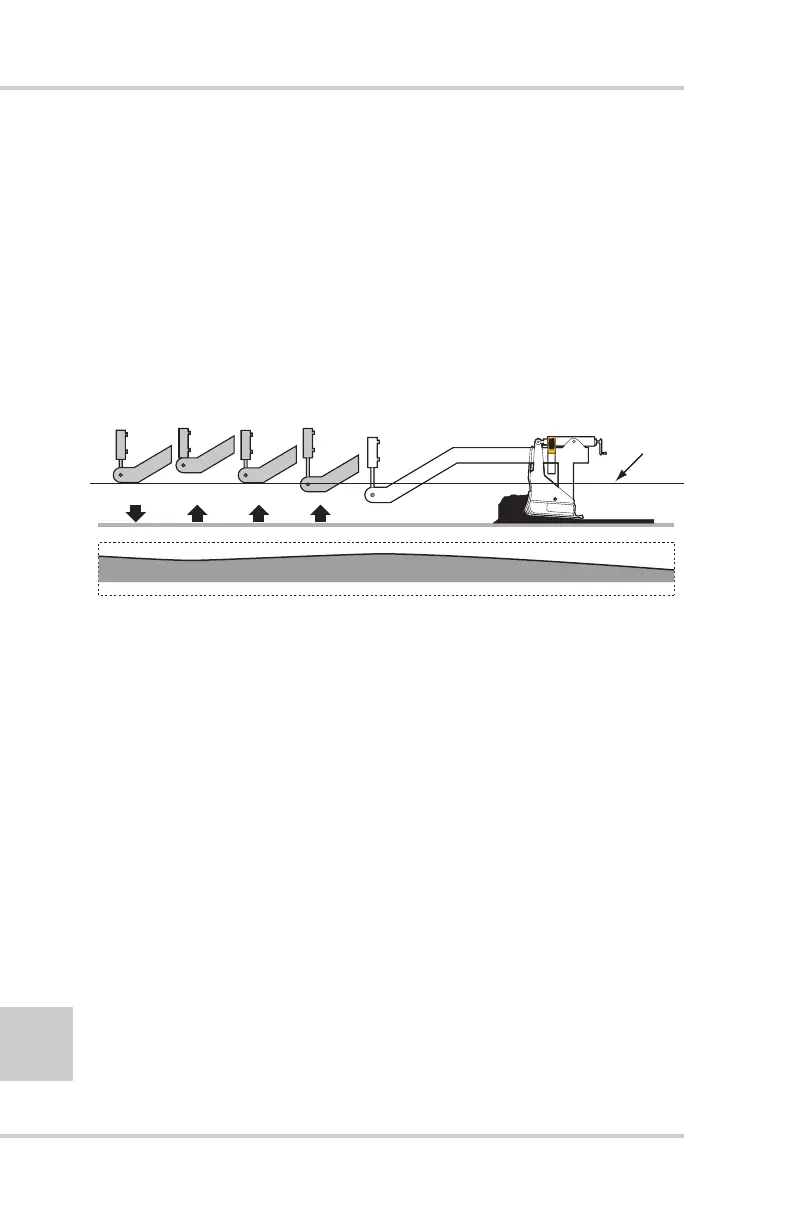

immediately to the tow point movement, so the tracker

continues to send raise correct signals to the valve. By the time

the screed gets to grade (approximately 3 tow arm lengths), the

tow point cylinder has moved too far, causing the screed to

continue raising. The tracker senses this over correction and

sends a lower signal to the tow point cylinder, repeating the

whole process in the other direction. Therefore, with the tracker

mounted at the screed pivot point, long waves in the mat will be

produced because there is no feedback from the tow point

cylinder to the screed (Figure 6-12).

Figure 6-12. Tracker at Screed Pivot Point Causes Erroneous Corrections

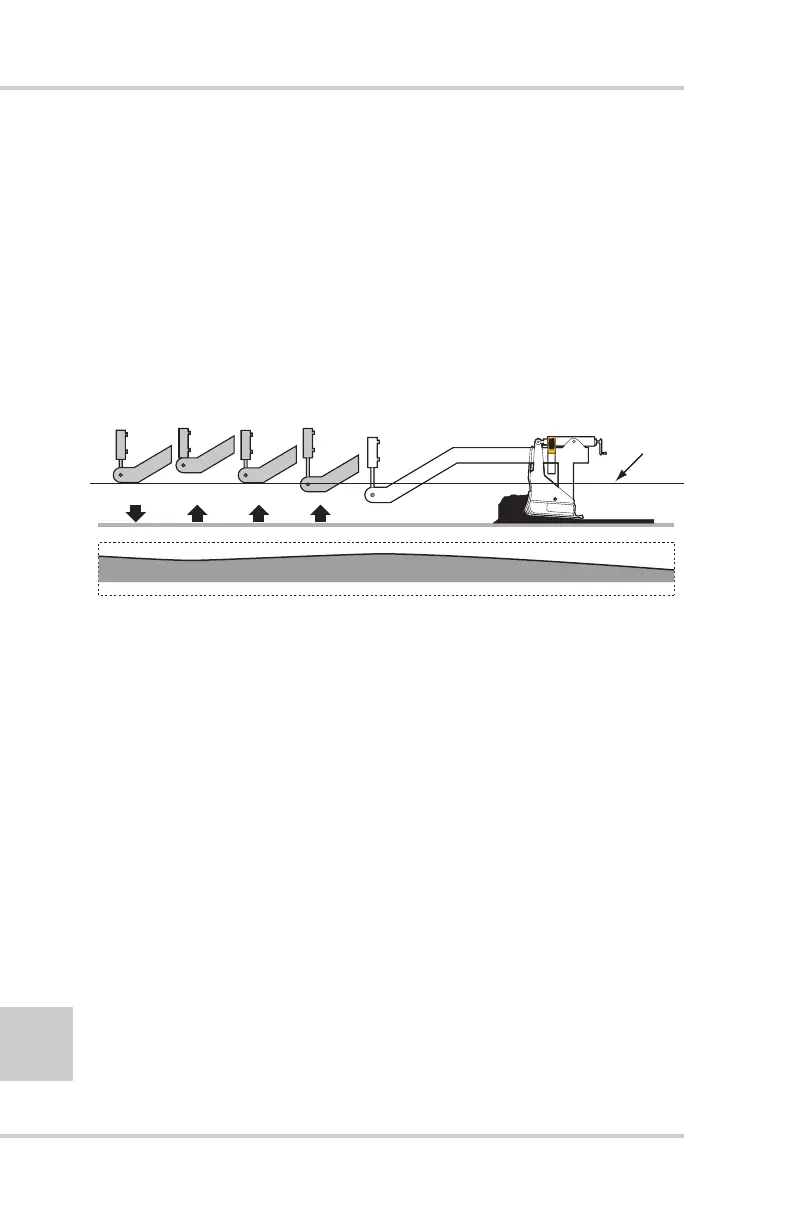

• Example 2: Tracker Placed Incorrectly at Tow Point

At this point, where grade corrections are being made, the sonic

tracker is kept at an exact distance from the grade reference

(Figure 6-13 on page 6-11). Any tracker elevation changes will

cause the tow point cylinder to move immediately. The problem

with the tracker placed here is the lack of feedback from the

screed.

S

onic

T

racker

II

Reference

Average profile of mat with Sonic Tracker

TM

mounted at Screed

Loading...

Loading...