FilteringtheClosed-LoopTractionCircuit(MachineSerialNumber

above316000000)

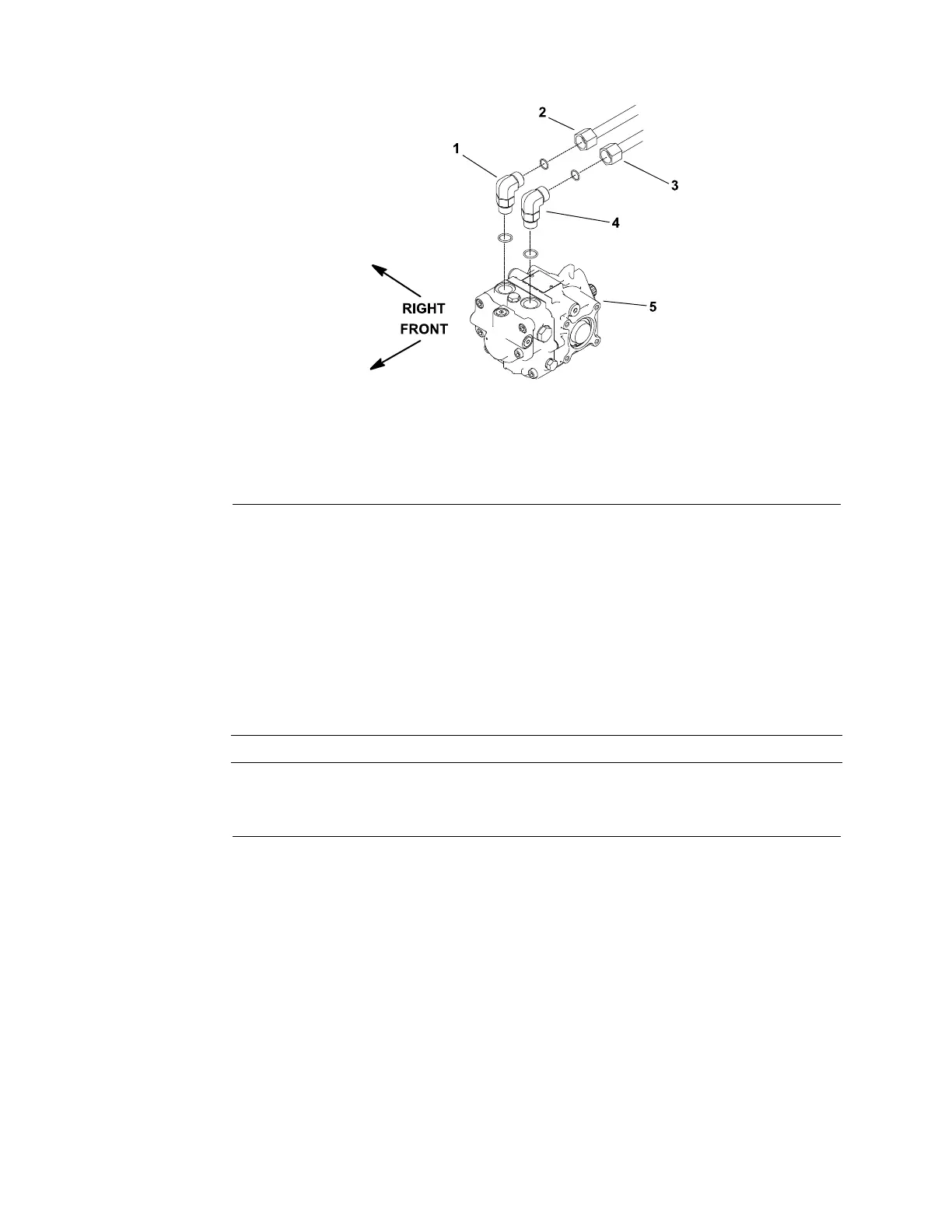

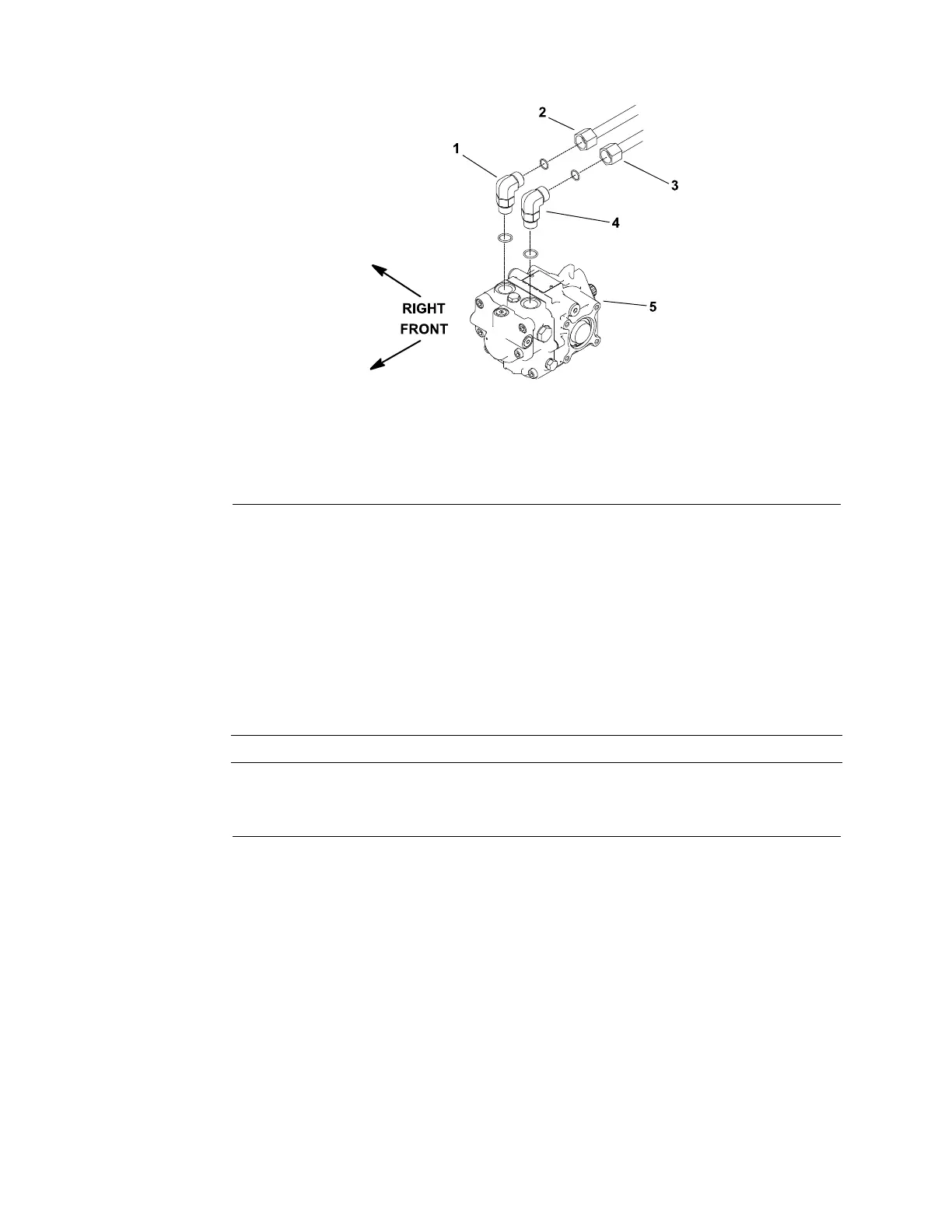

g225778

Figure78

1.Rightelbowtting4.Leftelbowtting

2.Hydraulictube(forward)

5.Hydraulicpump

3.Hydraulichose(reverse)

Filteringaclosed-loophydraulicsystemafteramajorcomponentfailure(e.g.,

hydraulicpumporhydraulicmotor)isnecessarytopreventunwantedmaterial

fromtransmittingthroughoutthesystem.Ifaclosed-loophydraulicsystem

lteringtoolisnotusedtoensurethesystemcleanliness,repeatfailures,aswell

assubsequentdamagetootherhydrauliccomponentsintheaffectedsystem,

willoccur.Toeffectivelyremovethecontaminationfromtheclosed-looptraction

circuit,usetheTorohighowhydrauliclterandhydraulichosekits(referto

SpecialT ools(page5–39)).

1.Parkthemachineonalevelsurface,shutoftheengine,andremovethekey

fromthekeyswitch.

IMPORTANT

Beforeliftingthemachinewithajack,reviewandfollowJacking

Instructions(page1–6).

2.Liftandsupportthemachinesothatallthewheelsareofftheground.

Note:Ifthehydraulicmotorwasreplaced,installahigh-owltertotheinlet

ofthenewmotorinsteadoftothehydraulicpumptting.Thiswillprevent

systemcontaminationfromenteringanddamagingthenewhydraulicmotor.

3.Cleanthejunctionofthehydraulichoseandleftelbowttingatthetopofthe

hydraulicpump(Figure78).Disconnectthehosefromtheleftpumptting.

4.ConnecttheT orohighowhydrauliclterinseriesbetweenthehydraulic

pumpttingandthedisconnectedhose.Usethehydraulichosekit(referto

HydraulicHoseKit(page5–40))toconnecttheltertothemachine.Ensure

thatthettingandhoseconnectionsareproperlytightened.

HydraulicSystem:ServiceandRepairs

Page5–82

Groundsmaster

®

3280-D/3320

05138SLRevB

Loading...

Loading...