PinionGeartoRingGearEngagement(4-WheelDriveAxle)

Thenalpositionofthepiniongearisveriedbyusingthegearcontactpattern

methodasdescribedinthefollowingprocedure.

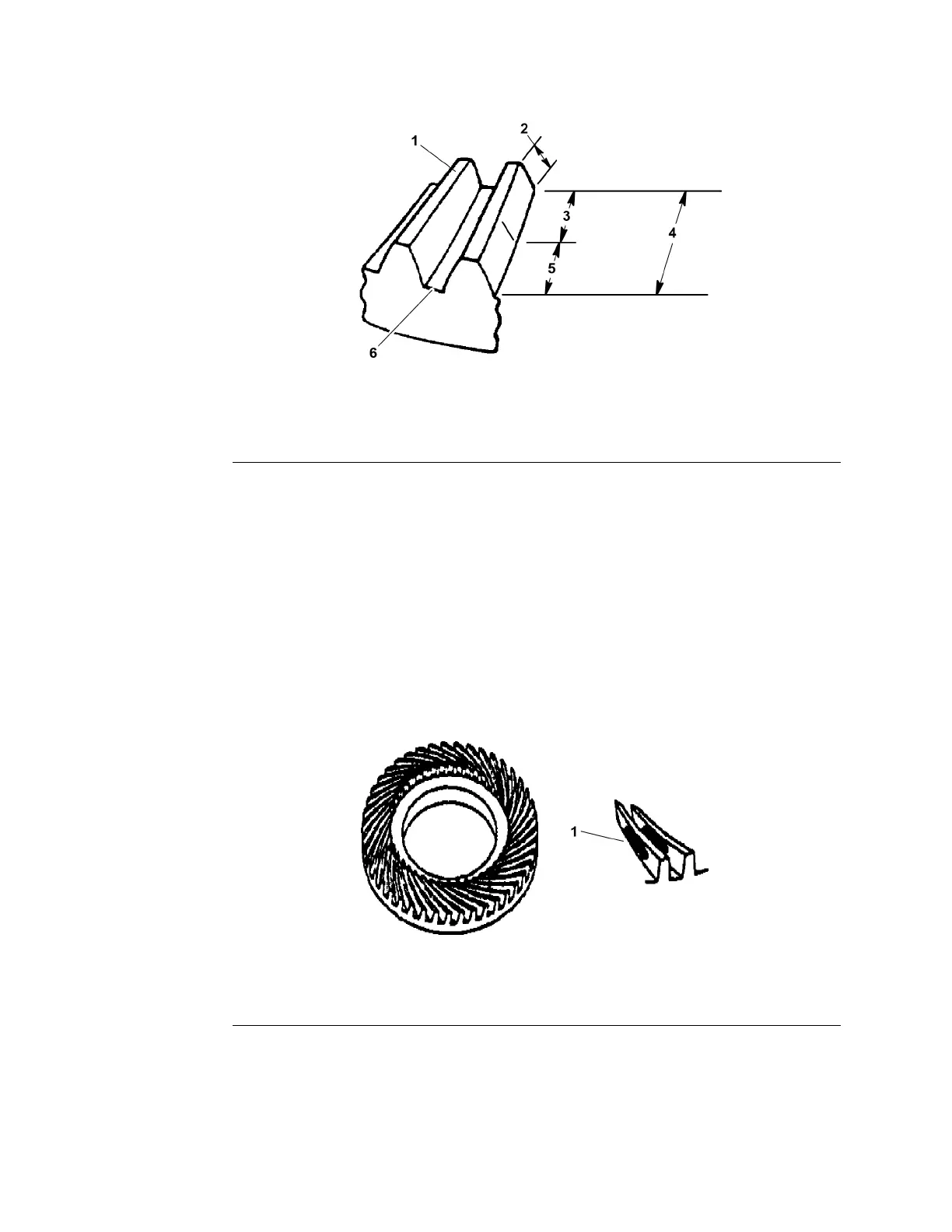

g226500

Figure282

1.T opland3.T oe5.Heel

2.Prole

4.Lengthwisebearingarc6.Root

Geartoothdenitions(Figure282):

•Toe-theportionofthetoothsurfaceattheendtowardthecenter.

•Heel-theportionofthegeartoothattheouterend.

•TopLand-topsurfaceoftooth.

1.Painttheteethoftheringgear,bothdriveandcoastside,withagearmarking

compound,suchasDyKemsteelblue.

2.Installtheinputshaft/piniongearassemblyintotheaxlecase.

3.Whileapplyingalightloadtotheringgear,rotatethepiniongearinthe

directionofforwardtraveluntiltheringgearhasmade1completerevolution.

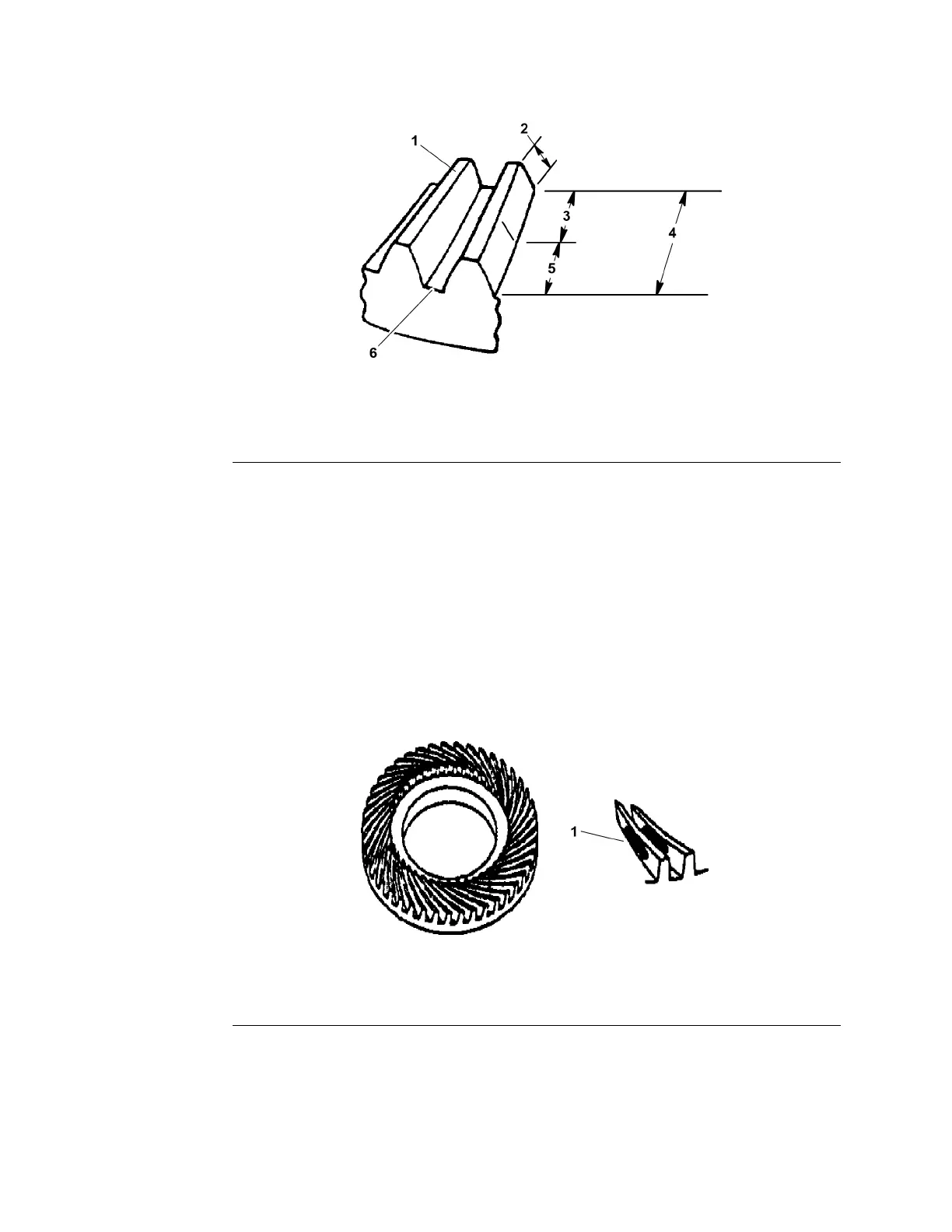

g226501

Figure283

1.Morethan35%totaltoothcontact

Idealtoothcontactobservedontheringgearshouldcovermorethan35%of

eachtoothsurface.Thecontactareashouldbeinthecenterofeachtooth

andextend1/3to1/2wayacrosseachtoothfromthetoeend(Figure283).

DriveAxles:ServiceandRepairs

Page8–70

Groundsmaster

®

3280-D/3320

05138SLRevB

Loading...

Loading...