E6582175

F-57

6

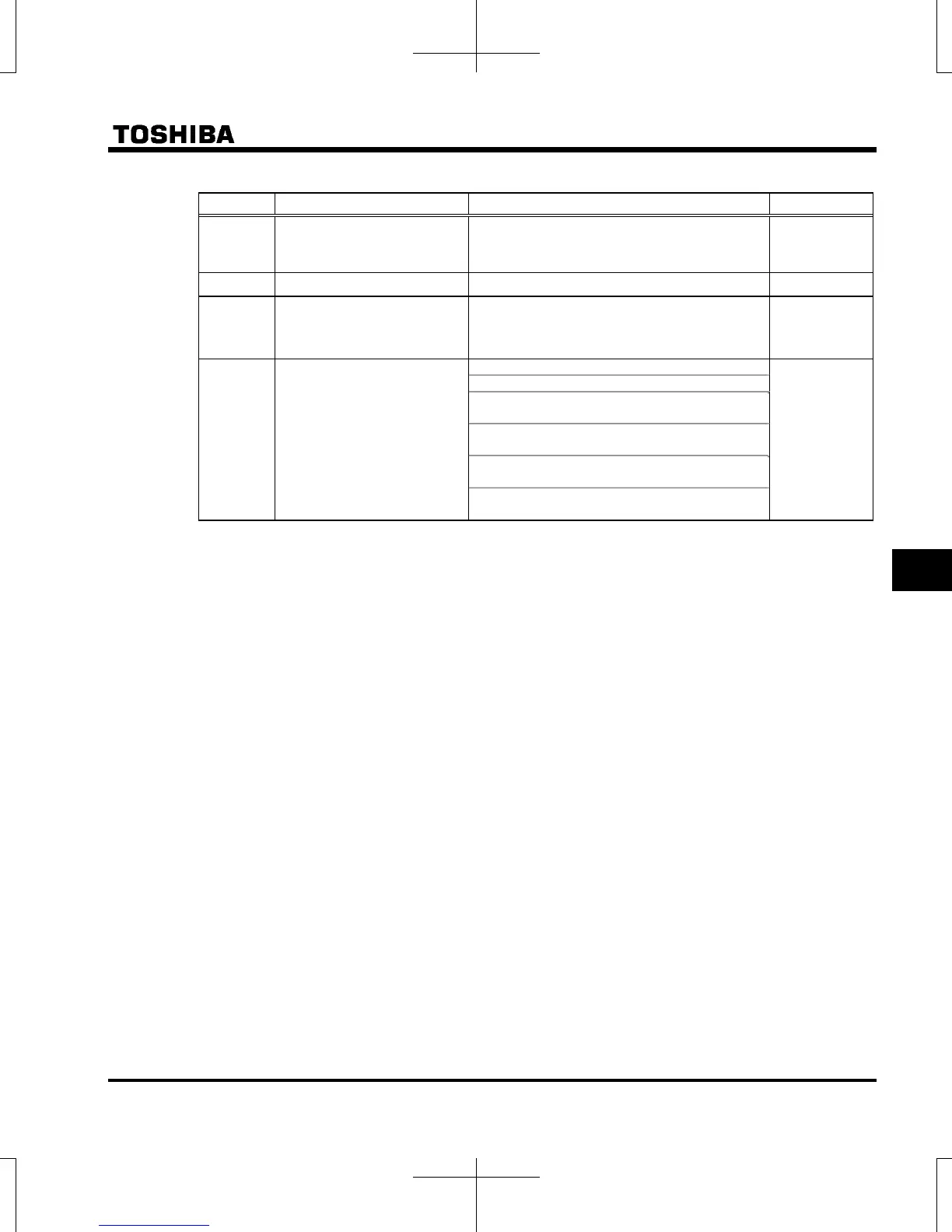

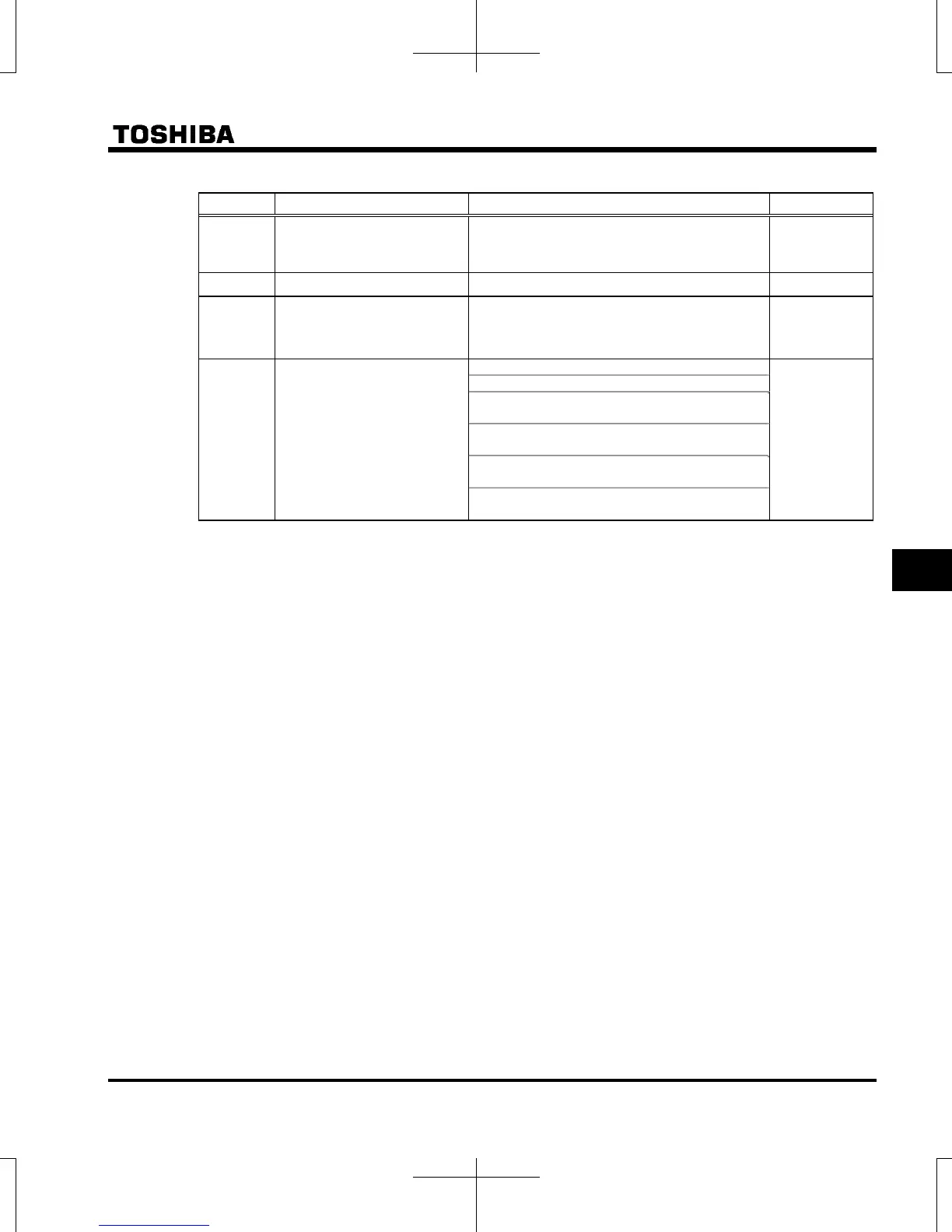

[Parameter setting]

Title Function Adjustment range Default setting

aul

Overload characteristic

selection

0: -

1: Constant torque characteristic(150%-60s)

2: Variable torque characteristic(120%-60s)

0

f300

PWM carrier frequency 2.0-16.0 (kHz) 12.0

f312

Random mode

0: Disabled

1: Random mode 1

2: Random mode 2

3: Random mode 3

0

f316

PWM carrier frequency

control mode selection

0: Carrier frequency without reduction

1

(240V class)

5

(500V class)

1: Carrier frequency with automatic reduction

2: Carrier frequency without reduction

(Support for 500V models) pattern 1

3: Carrier frequency with automatic reduction

(Support for 500V models) pattern 1

4: Carrier frequency without reduction

(Support for 500V models) pattern 2

5: Carrier frequency with automatic reduction

(Support for 500V models) pattern 2

Note 1: By f300 setting and ambient temperature, current reduction may be required.

Refer to the table on the following page.

Note 2: PWM carrier frequency is increased automatically at high output frequency range (100 Hz or more) for

stable operation, even if f300 is set to low PWM carrier frequency.

Note 3: When f300 is set to 8kHz or less, the random mode is exercised in the low output frequency range

where an annoying magnetic noise of the motor is generated.

Select the proper tone from the three kinds of f312 = 1, 2, 3 for the machinery.

Note 4: When f316 is set to “Carrier frequency without reduction”, oh (overheat) or ol3 (main module

overload) trip can occur easily.

Reduce f601 or f185(stall prevention level) properly to avoid the trip.

Note 5: When reducing the voltage surge to the motor, set f316 to 2 or 3.

Use by setting f300 to 4kHz or less, to avoid the output voltage drop.

Note 6: When reducing the voltage surge to the motor, set f316 to 4 or 5.

However, when the machinery (load) is resonated and the cable length between the inverter and the

motor is long (30m or more), use by setting f300 to 4kHz or less.

Loading...

Loading...