106

CDHH-SVX003C-EN

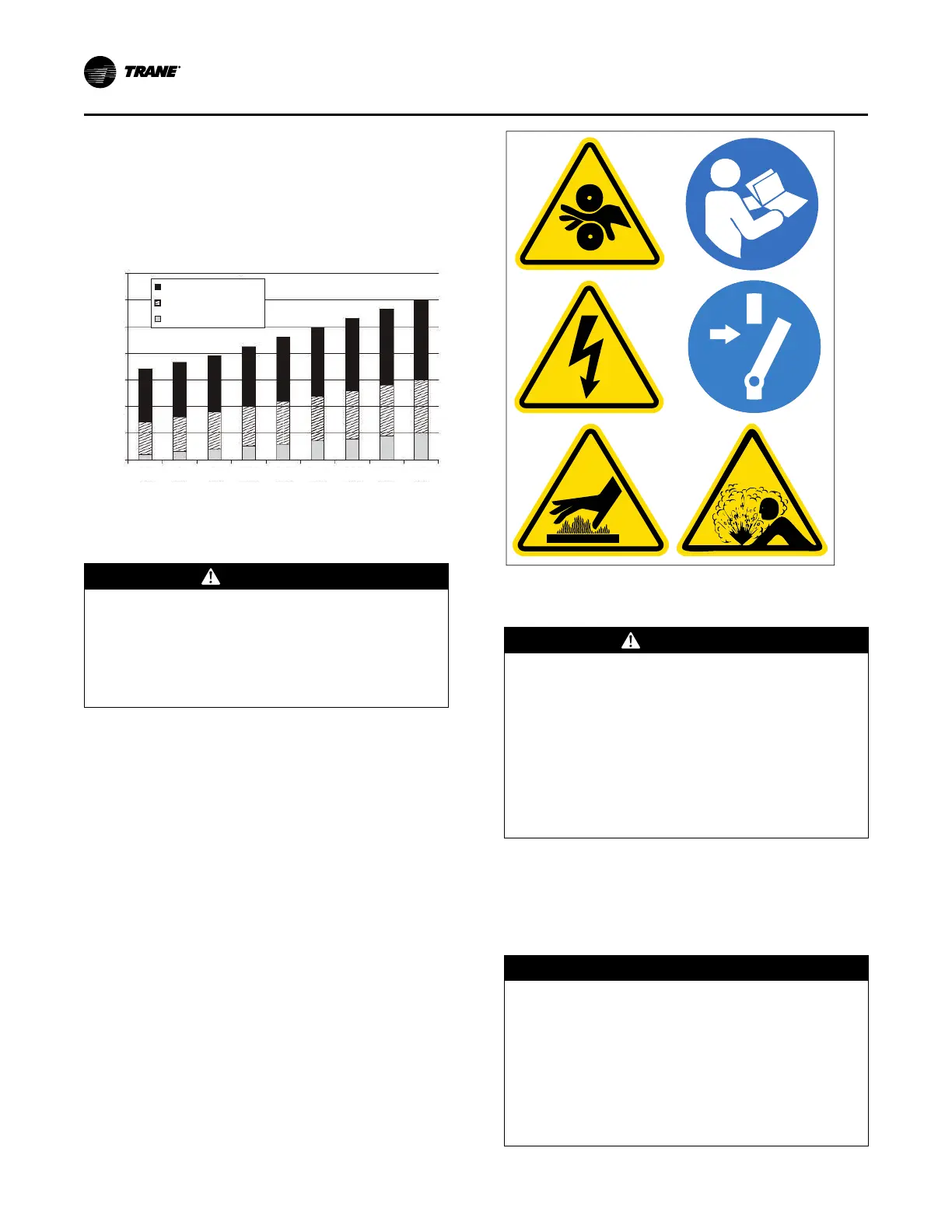

If the purge pump-out time is in the small leak region, then

a leak check should be performed and all leaks repaired at

the earliest convenience. If the purge pump-out time is in

the large leak region, a thorough leak check of the unit

should be performed immediately to find and fix the leaks.

Figure 70. Purge operation under typical and leak

conditions

Large Leak

Small Leak

Typical Operation

Purge Minutes per Day

Chiller Tons per Circuit

140

120

100

80

60

40

20

0

400 600 800 1000 1200 1400 1600 1800 2000

Leak Testing

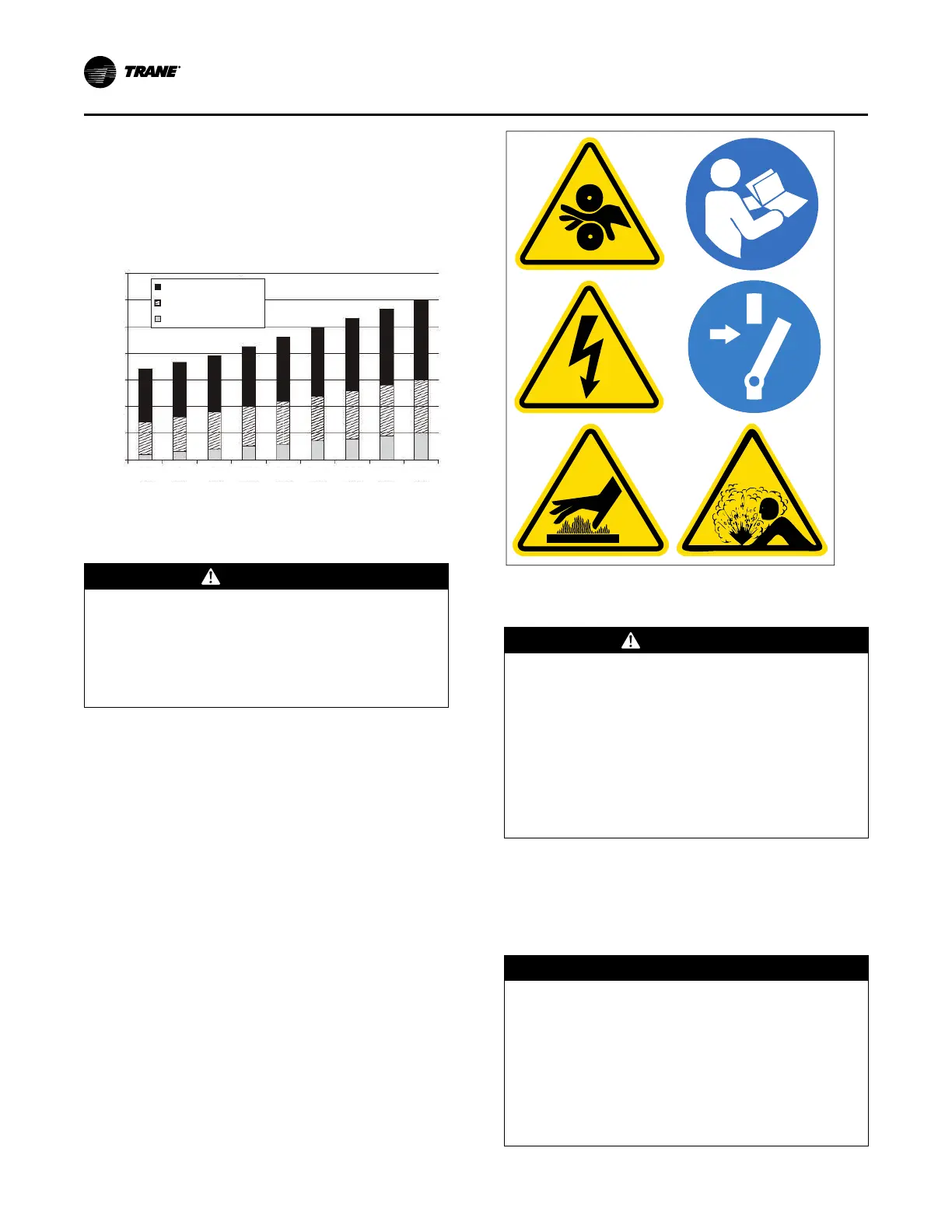

WARNING

Explosion Hazard!

Failure to follow safe leak test procedures below

could result in death or serious injury or equipment or

property-only-damage.

Never use an open flame to detect gas leaks. Use a

leak test solution for leak testing.

Note: Graphic labels (shown above) are used for CE

application only.

WARNING

Hazardous Pressures!

Failure to follow instructions below could result in a

violent explosion, which could result in death or

serious injury.

If a heat source is required to raise the tank pressure

during removal of refrigerant from cylinders, use only

warm water or heat blankets to raise the tank

temperature. Do not exceed a temperature of 150°F.

Do not under any circumstances apply direct flame to

any portion of the cylinder.

Important: If leak testing is required, contact a Trane

Service Agency.

Recommended System

Maintenance

NOTICE

Proper Water Treatment Required!

The use of untreated or improperly treated water

could result in scaling, erosion, corrosion, algae or

slime.

Use the services of a qualified water treatment

specialist to determine what water treatment, if any, is

required. Trane assumes no responsibility for

equipment failures which result from untreated or

improperly treated water, or saline or brackish water.

Recommended Maintenance

Loading...

Loading...