54

CDHH-SVX003C-EN

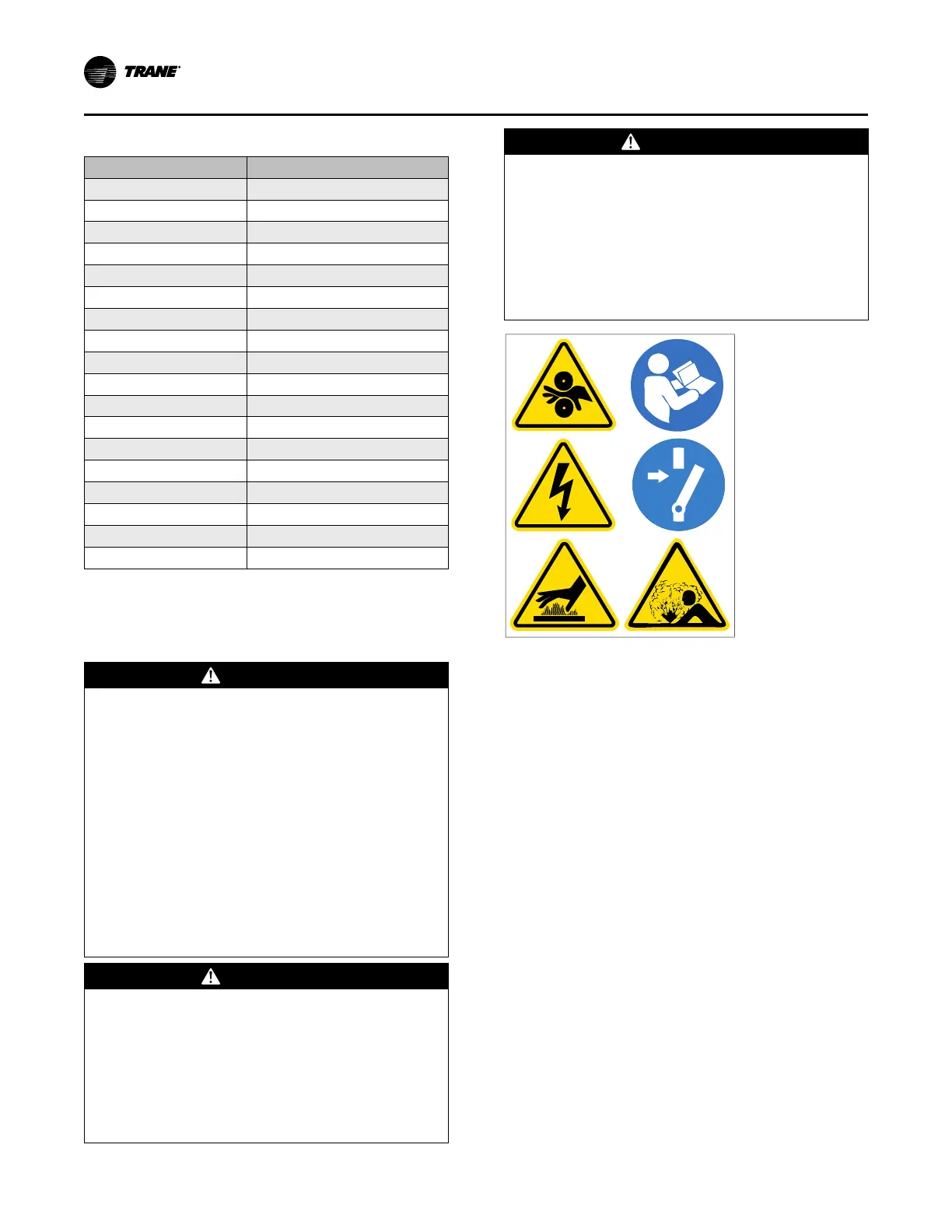

Table 16. Wire sizing reference (continued)

AWG/MCM

mm

2

Equivalent

20 0.5

18 0.75

17 1.0

16 1.5

14 2.5

12 4

10 6

8 10

6 16

4 25

2 or 1 35

1/0 50

2/0 70

2/0 or 3/0 95

4/0 or 250 120

300 150

350 or 400 185

450 or 500 240

Note: AWG = American Wire Gauge.

Important: Customers are responsible for all field wiring in

compliance with international, national, and/or

local codes.

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious

injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by

Trane or others, refer to the appropriate

manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with a CAT III or IV

voltmeter rated per NFPA 70E that all capacitors have

discharged.

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear PPE and follow proper handling

guidelines could result in death or serious injury.

Always wear appropriate personal protective

equipment in accordance with applicable regulations

and/or standards to guard against potential electrical

shock and flash hazards.

WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions when

exposed to live electrical components could result in

death or serious injury.

When it is necessary to work with live electrical

components, have a qualified licensed electrician or

other individual who has been properly trained in

handling live electrical components perform these

tasks.

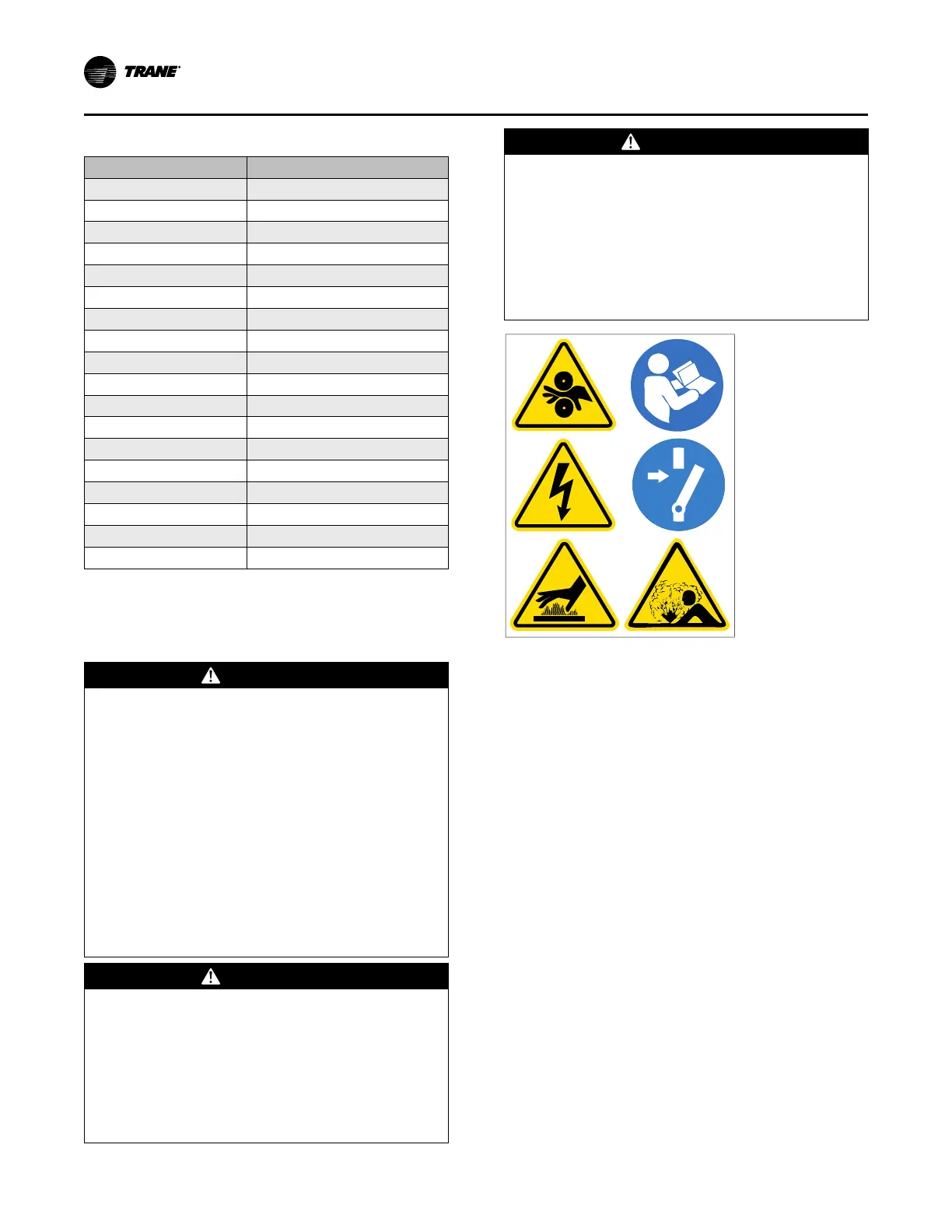

Note: Graphic labels (shown above) are used for CE

application only.

Important:

• Before servicing, disconnect all power

sources and allow at least 30 minutes for

capacitors to discharge.

• All electrical enclosures—unit or remote—

are IP2X.

Trane-supplied Remote Starter

Wiring

This information is applicable to Starter 1 for Compressor 1

as well as Starter 2 for Compressor 2. (For wire estimation

purposes, double check the following table as there are two

starters to be wired.).

Important: The information in the table below is applicable

to Standard Starters or Drive Options. Consult

As-Builts, Submittal and/or consult Tech

Support for Sales orders with design special

drives and starters.

Electrical Requirements

Loading...

Loading...