14

CDHH-SVX003C-EN

local waste management office for the proper procedures

on handling, disposal, transporting, and storage of oil, oil

filters, refrigerant filters, and filter dryer cores.

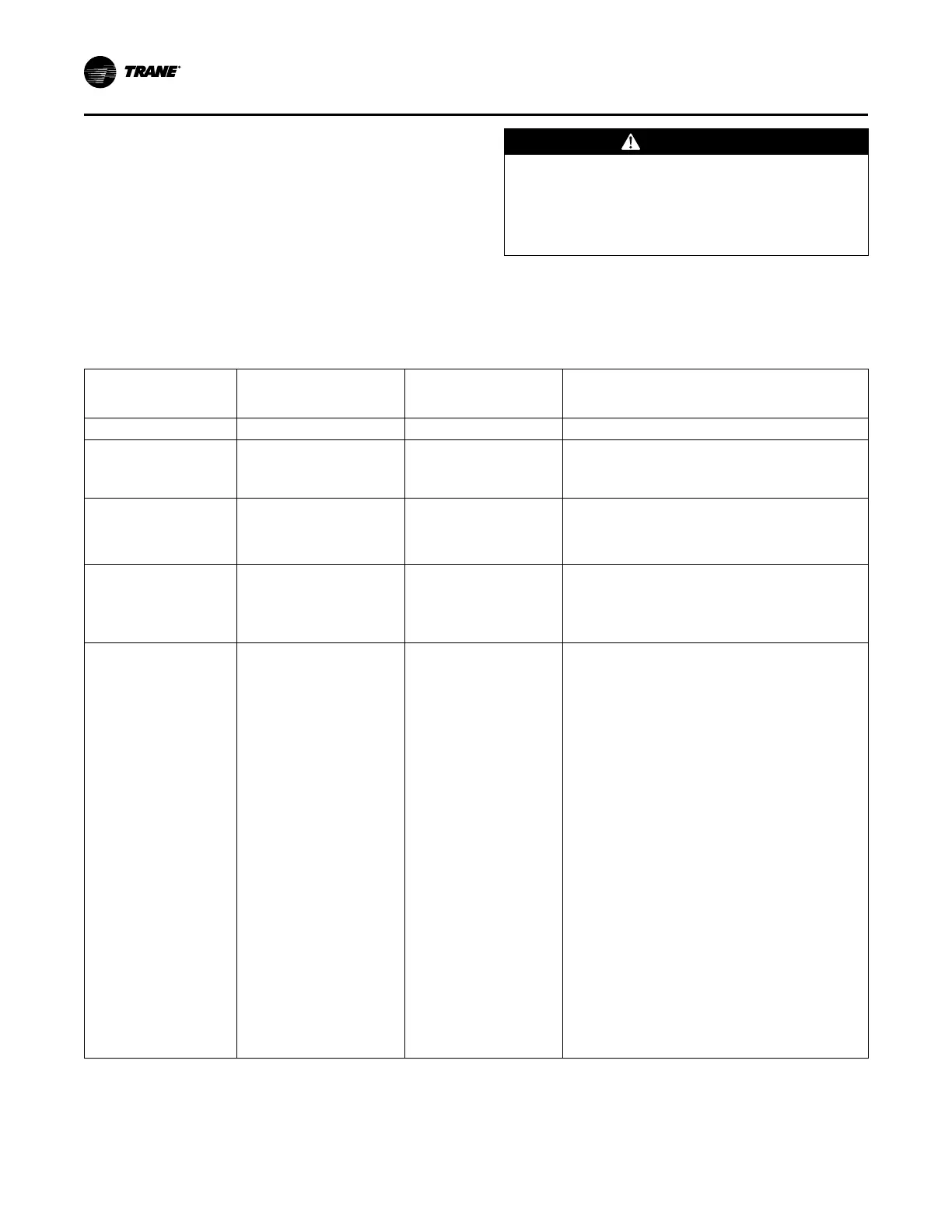

Installation Requirements and

Contractor Responsibilities

A list of the contractor responsibilities typically associated

with the unit installation process is provided in the following

table.

WARNING

Combustible Material!

Failure to follow instructions below could result in

death , serious injury, or equipment damage.

Shrink-wrap is a combustible material. Avoid open

flames and hot sparks.

Notes:

1. The chiller should remain within its protective

shrink-wrap covering during storage.

2. These chillers are assembled with metric

fasteners.

Type of Requirement

Trane Supplied

Trane Installed

Trane Supplied

Field Installed

Field Supplied

Field Installed

Foundation

Meet foundation requirements

Rigging

• Safety chains

• Rigging shackles

• Lifting beam

Disassembly/Reassembly

(as required)

Trane will perform or have direct

on-site supervision of the

disassembly and reassembly work

(contact your local Trane office for

pricing)

Isolation

Isolation pads or spring isolators

• Isolation pads or spring isolators

• Optional spring isolators, when required, are installed by

others; do NOT overload springs and do NOT install

isolation springs if they block serviceable parts such as the

oil tank system, service valves, etc.

Electrical

• Circuit breakers or fusible

disconnects (optional)

• Unit-mounted starter

(optional)

• Power factor correction

capacitors (PFCCs)

(optional)

• Jumper bars

• Temperature sensor

(optional outdoor air)

• Flow switches (may be

field supplied); for

installation instructions for

the ifm efector® flow

detection controller and

sensor, refer to “Water

Flow Detection Controller

and Sensor – ifm

efector,” p. 28 or Trane

literature that shipped with

the device

• Remote-mounted starter

(optional)

• Air-Fi

• Wi-Fi

• Circuit breakers or fusible disconnects (optional)

• Electrical connections to unit-mounted starter (optional)

• Electrical connections to remote-mounted starter

(optional)

• Wiring sizes per submittal and National Electric Code

(NEC) or local codes

• PFCCs (remote mounted starter optional only)

• Terminal lugs

• Ground connection(s)

• Jumper bars

• BAS wiring (optional)

• Inter-processor communication (IPC) wiring(AFD and

remote-mounted starters only)

• Control voltage wiring (AFD and remote-mounted starters

only)

• Oil pump interlock wiring (AFD and remote mounted

starters only)

• High condenser pressure interlock wiring (AFD and

remote-mounted starters only)

• Chilled water pump contactor and wiring including

interlock

• Condenser water pump contactor and wiring including

interlock

• Option relays and wiring

Pre-Installation

Loading...

Loading...