30

CDHH-SVX003C-EN

confirm flow prior to starting a unit and to stop a running

unit if flow is lost. For troubleshooting, a viewable

diagnostic is generated if a proof of flow switch does not

close when flow is required.

Evaporator and Condenser

Water Piping

The following two figures illustrate the recommended

(typical) water piping arrangements for the evaporator and

condenser.

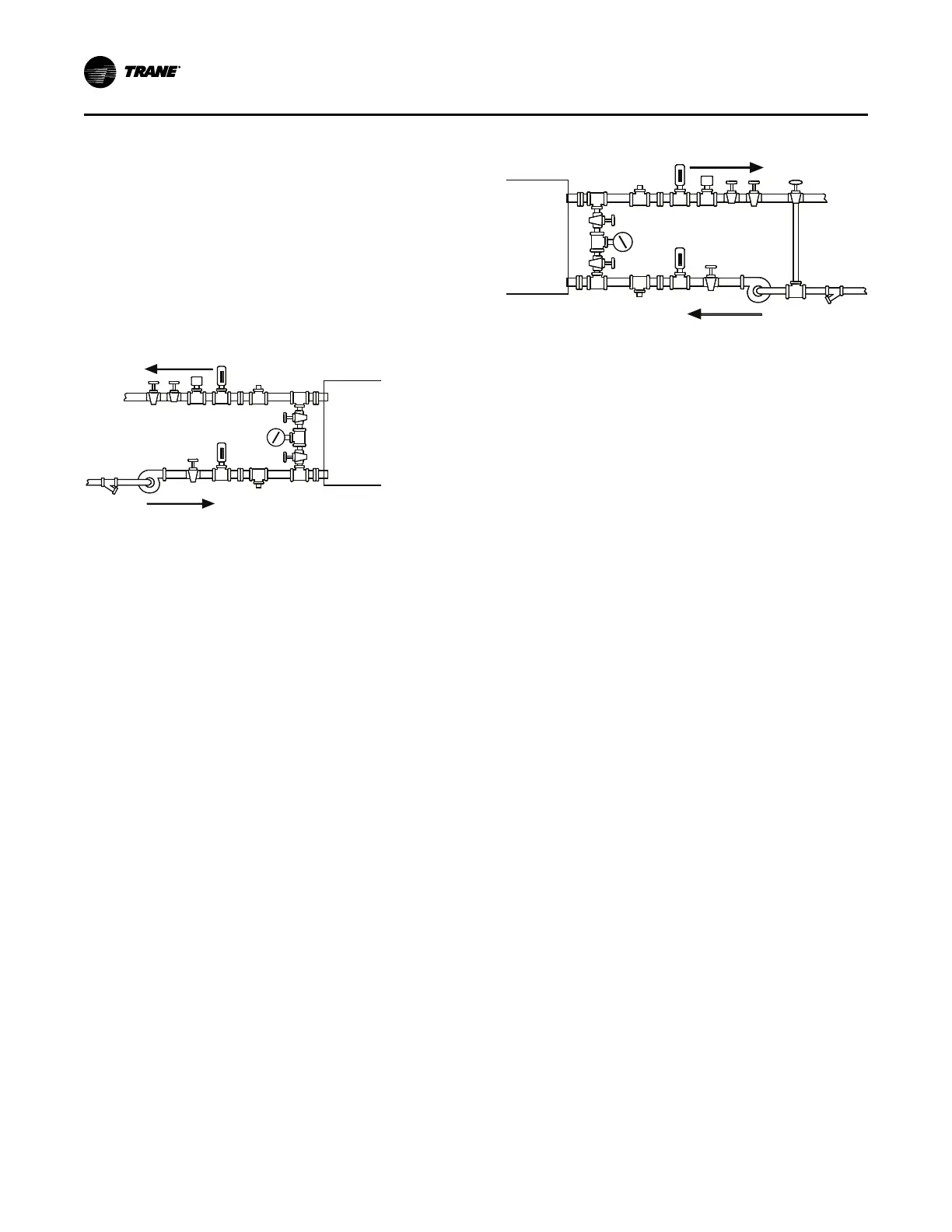

Figure 15. Typical evaporator water piping circuit

4

45

53

3

7

2

2 1

9

6

2

2

8

Outlet

Inlet

1. Balancing valve.

2. Gate (Isolation) valve or ball valve.

3. Thermometer (if field supplied).

4. Waterbox nozzle connection.

5. Drain, vent, and anode.

6. Strainer.

7. Chilled water flow switch (4B4). Flow switch 4B4 may

be installed in either the entering or leaving leg of the

chilled water circuit.

8. Pump.

9. Pressure gauge. It is recommended to pipe the gauge

between entering and leaving pipes. A shutoff valve on

each side of the gauge allows the operator to read

either entering or leaving water pressure.

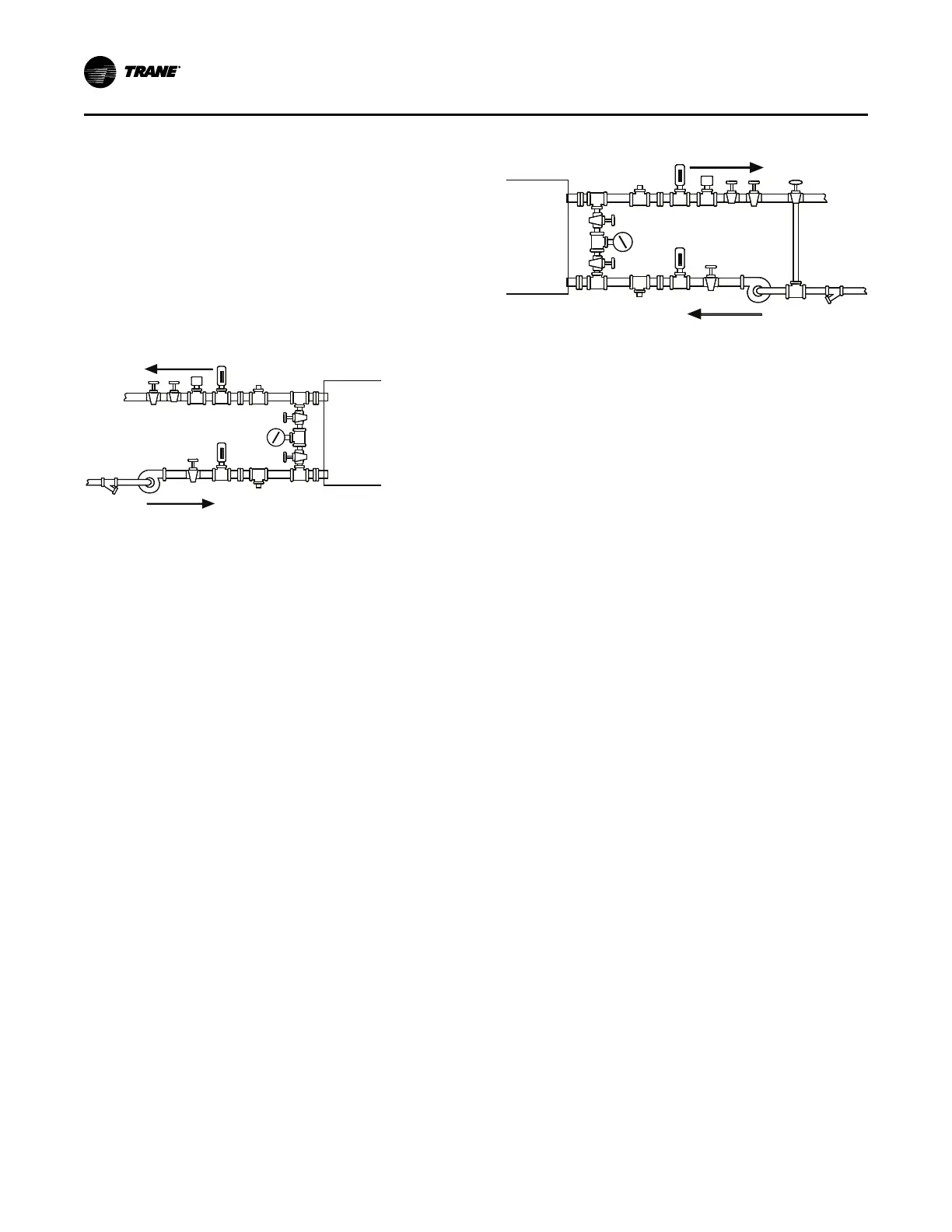

Figure 16. Typical condenser water piping circuits

1 2

3

4 5

6

7 8

92

3

4 5

2

2

10

Outlet

Inlet

1. Balancing valve.

2. Gate (isolation) valve or ball valve.

3. Thermometer (if field supplied).

4. Waterbox nozzle connection.

5. Drain, vent, and anode.

6. Strainer.

7. Condenser water flow switch (4B5). Flow switch 4B5

may be installed in either the entering or leaving leg of

the water circuit.

8. Three-way valve (optional).

9. Condenser water pump.

10. Pressure gauge. It is recommended to pipe a single

gauge between entering and leaving pipes.

Notes:

• Some type of field-supplied temperature control

device may be required to regulate the

temperature of the heat-recovery condenser

water circuit. For application recommendations,

refer to Heat Recovery Seminar (Part 2):

Systems/Equipment (AM-FND-8).

• Install a bypass valve system to avoid

circulating water through the auxiliary shell

when the unit is shutdown.

• On multiple-pass condensers, entering

condenser water must enter at the lowest

nozzle.

Piping must be arranged and supported to avoid stress on

the equipment. It is strongly recommended that the piping

contractor does not run pipe closer than 3 ft (0.9 m)

minimum to the equipment. This will allow for proper fit

upon arrival of the unit at the job site. Any adjustment that

is necessary can be made to the piping at that time.

Expenses that result from a failure to follow this

recommendation will NOT be paid by Trane.

Waterboxes with multiple pass arrangements utilize a

baffle to separate the passes. These baffles are designed

for a maximum pressure of 20 psid (137.9 kPaD). If larger

pressure drops are expected in the application, contact

your local Trane representative to discuss special waterbox

options.

Important: Water flows must be piped in accordance with

nameplate designation.

Installation: Water Piping

Loading...

Loading...