CDHH-SVX003C-EN

29

Note: When installed, the tip of the ifm efector® sensor

probe must be at least 1 in. (2.54 cm) away from

any pipe wall. Do NOT insert more than 3.5 in.

(8.9 cm) of the probe length into the pipe.

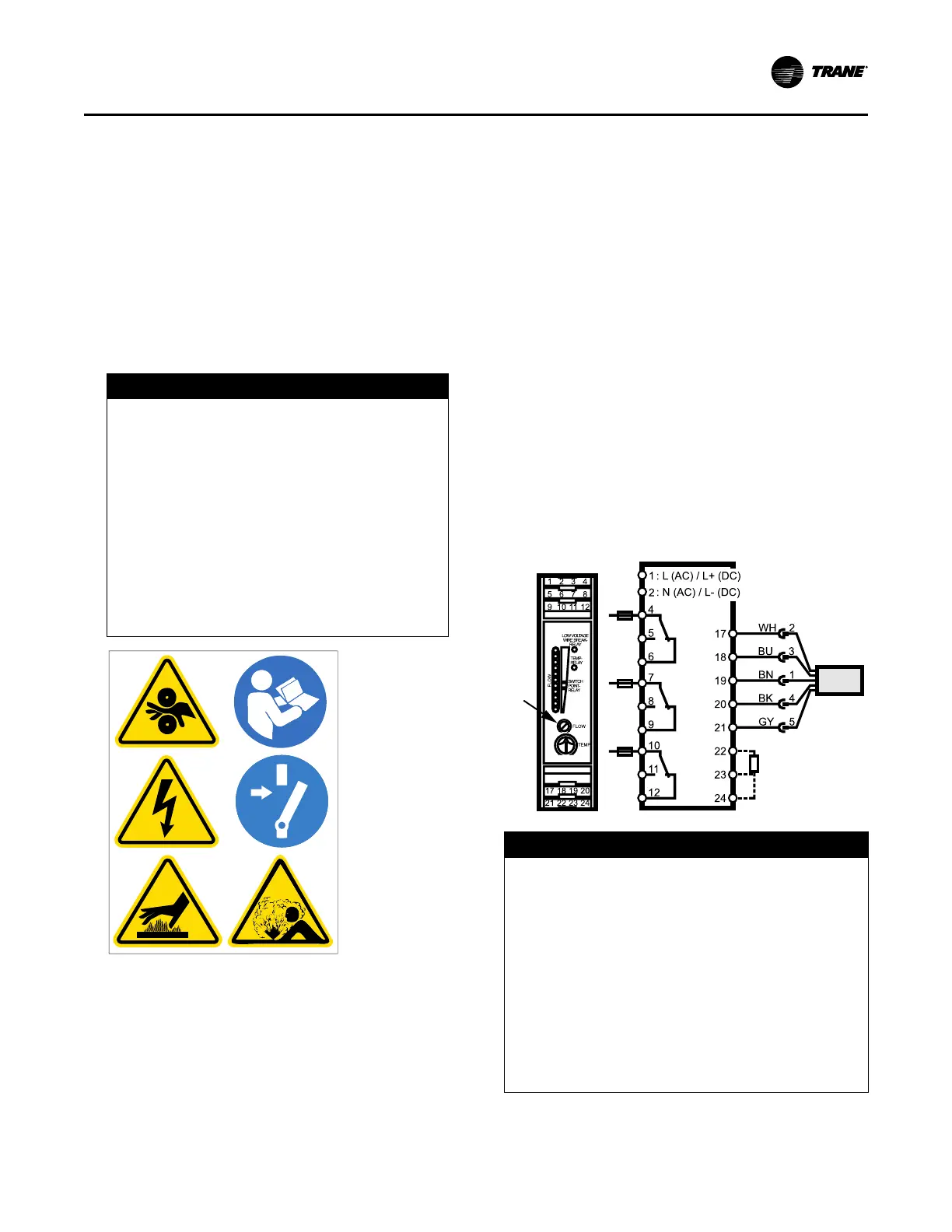

3. Install the Micro DC Cable by inserting it through the

wire openings on the back side of the control panel

(see item labeled “3” in the preceding figure). Install the

supplied Micro DC Cable (29.5 ft [9 m] in length) to the

Flow Probe and hand-tighten the connector nut.

4. Plug the other end of the Micro DC Cable into the Flow

Control Monitor with the Combicon connector (see item

labeled “4” in the preceding figure). Refer to the

following figure for cable wiring.

NOTICE

Do Not Apply Electrical Power to a

Unit in a Vacuum!

Failure to follow instructions below could result in

motor and compressor damage.

Do not apply electrical power to a motor in a

vacuum.

For units with inside-the-delta solid state starters,

disconnect power to unit during evacuation or

when the unit is in a deep vacuum. In addition, on

units with inside-the-delta solid state starters, all

power to the unit must be disconnected prior to

evacuating the unit as line power is directly

applied to the motor terminals 4, 5, and 6.

Note: Graphic labels (shown above) are used for CE

application only.

Important:

• Before servicing, disconnect all power

sources and allow at least 30 minutes

for capacitors to discharge.

• All electrical enclosures—unit or

remote—are IP2X.

5. Apply power to the chiller control panel to verify the

Flow Control Monitor has power and the Low Volt

Broken Wire Relay light is NOT lit.

6. Remove all air from the piping circuit prior to adjusting

the low water flow setpoint.

7. Reduce the water flow to the minimum allowable flow

and adjust the Flow setting on the Flow Control Monitor

(see item labeled “7” in the following figure). Adjusting

the “Flow” potentiometer clockwise (+) reduces the flow

setting cutout and adjusting counterclockwise (-)

increases the flow setting cutout.

Note: The “Temp” potentiometer on the ifm efector®

control module has no effect in Trane application.

It is NOT necessary to make adjustments to the

“Temp” potentiometer.

8. After the cutout setting is adjusted, the cutout setpoint

will be indicated with a yellow light on the Flow Control

Monitor LED bar graph display. When the water flows

are higher than the cutout, a green light will indicate

proper flow status. If the flows fall below the cutout

setpoint, a red light will indicate low/no flow status.

Figure 14. ifm efector® flow sensing device terminal

connection

NOTICE

Proof of Flow Switch!

Failure to provide flow switches or jumping-out of

switches could result in severe equipment damage.

Evaporator and condenser water circuits require

proof of flow switches.

• Failure to include the proof of flow devices and/or

jumping out these devices could cause the unit to

stop on a secondary level of protection.

• Frequent cycling on these higher level diagnostic

devices could cause excessive thermal and pressure

cycling of unit components (O-rings, gaskets,

sensors, motors, controls, etc.) and/or freeze damage,

resulting in premature failure of the chiller.

Evaporator and condenser proof of flow switches are

required. These switches are used with control logic to

Installation: Water Piping

Loading...

Loading...