32

CDHH-SVX003C-EN

Table 11. Water piping connection components

Unit Model

Unit Connection

Type

Customer Piping Connection

Victaulic

®

Flanged

CDHH

Flanged (optional)

Customer

provided

Victaulic

®

coupling

No adapter

required

CDHH

Victaulic

®

(all others)

Customer

provided

Victaulic

®

coupling

Trane provided

Victaulic

®

-to-

flange adapter

Figure 18. Customer piping connection types

Flanged Victaulic®

Waterbox

Waterbox

Customer

Flange Adaptor

Trane provided

Style 77 Flexible

Customer provided

Notes:

• Refer to the coupling manufacturer’s guidelines

for specific information concerning proper

piping system design and construction methods

for grooved water piping systems.

• Flexible coupling gaskets require proper

lubrication before installation to provide a good

seal. Refer to the coupling manufacturer’s

guidelines for proper lubricant type and

application.

Flange-connection Adapters

When flat-face flange connections are specified, flange-to-

groove adapters are provided (Victaulic® Style 741 for

150 psig [1034.2 kPaG] systems; Style 743 for 300 psig

[2068.4 kPaG] systems). The adapters are shipped

screwed to one of the chiller end-supports. Adapter

descriptions are given in the tables in “Victaulic Gasket

Installation,” p. 33. The flange adapters provide a direct,

rigid connection of flanged components to the grooved-pipe

chiller waterbox connections.

Figure 19. Typical shipping location for flange

In this case, the use of flexible type connectors (i.e.,

braided steel, elastomeric arch, etc.) are recommended to

attenuate vibration and prevent stress at the waterbox

connections.

All flange-to-flange assembly screws must be provided by

the installer. Hex head screw sizes and number required

are included in the tables in “Victaulic Gasket

Installation,” p. 33. The four draw-bolts needed for the

larger Style 741 (150 psig [1034.2 kPaG]) adapters are

provided. The Style 741 (150 psig [1034.2 kPaG]) flange

adapter requires a smooth, hard surface for a good seal.

Connection to other type flange faces (i.e., raised, serrated,

rubber, etc.) requires the use of a flange washer between

the faces. Refer to the flange adapter manufacturer’s

guidelines for specific information.

The flange-adapter gasket must be placed with the color-

coded lip on the pipe and the other lip facing the mating

flange.

NOTICE

Piping Connection Leaks!

Failure to provide effective seal could result in

equipment or property-only damage.

To provide effective seal, gasket contact surfaces of

adapter must be free of gouges, undulations or

deformities.

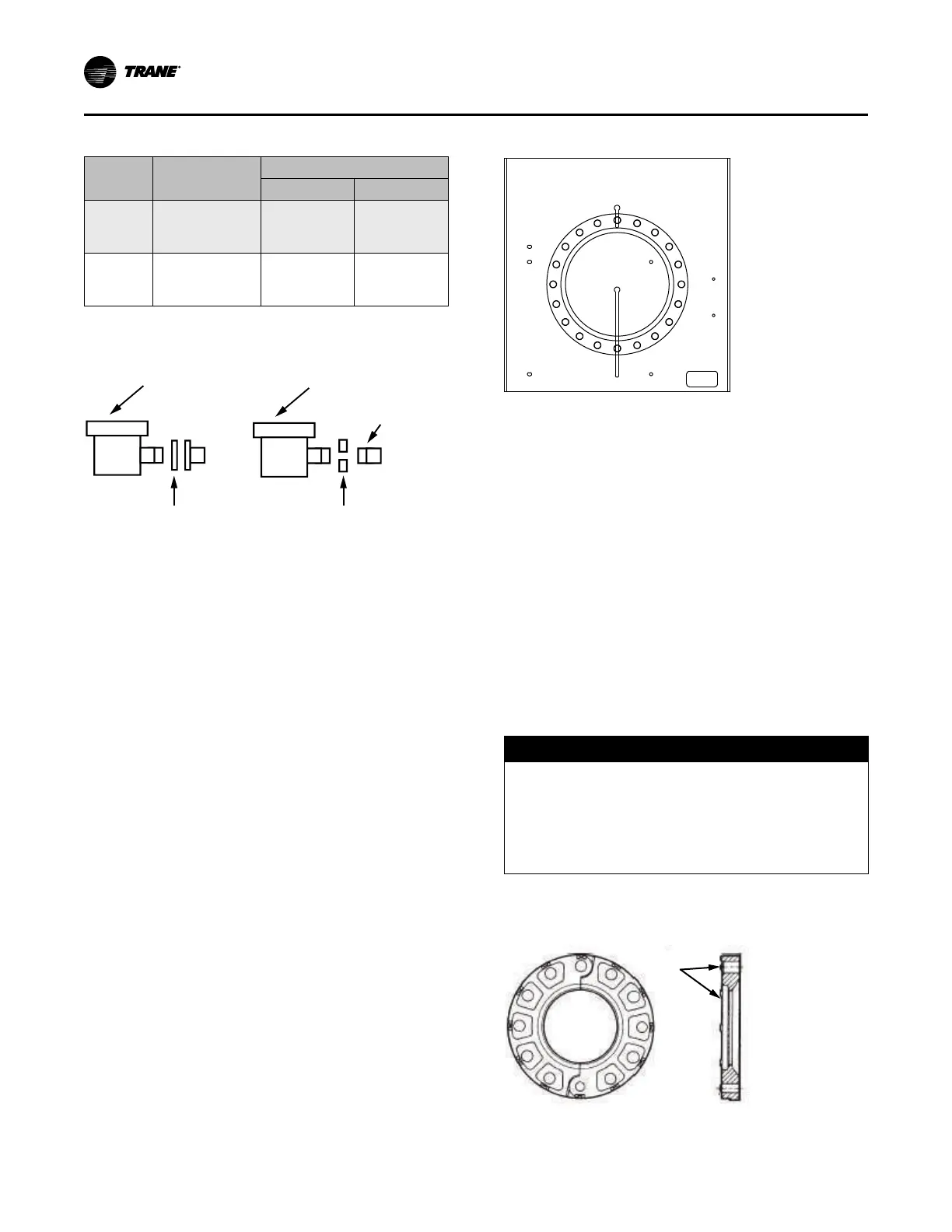

Figure 20. Modifying 300 psig (2068.4 kPaG) or 21 bar

flange adaptors for flat-faced flange application

Remove to mate

to flat-faced

flanges

Installation: Water Piping

Loading...

Loading...