CDHH-SVX003C-EN

77

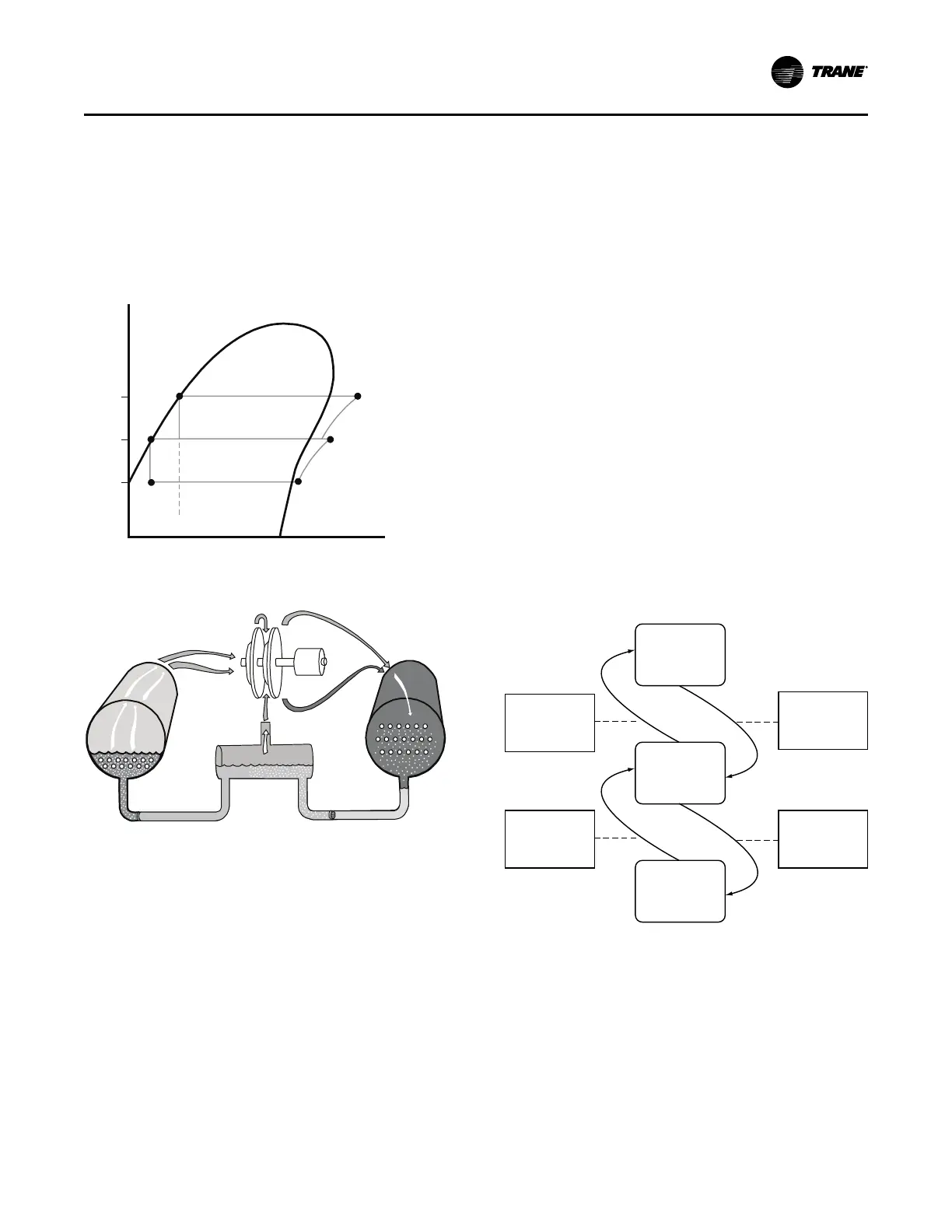

(refer to the following figure). Notice that some of the liquid

refrigerant flashes to a gas because of the pressure drop

created by the orifice plate, thus further cooling the liquid

refrigerant. This flash gas is then drawn directly from the

economizer into the second-stage impellers of the

compressor. All remaining liquid refrigerant flows out of the

economizer, passing through another orifice plate and into

the evaporator.

Figure 51. Pressure enthalpy curve

Condenser

Economizer

Evaporator

Compressor

Second Stage

Compressor

First Stage

6

5

4

3

1 2

Pressure

Enthalpy

P

3

P

1

P

2

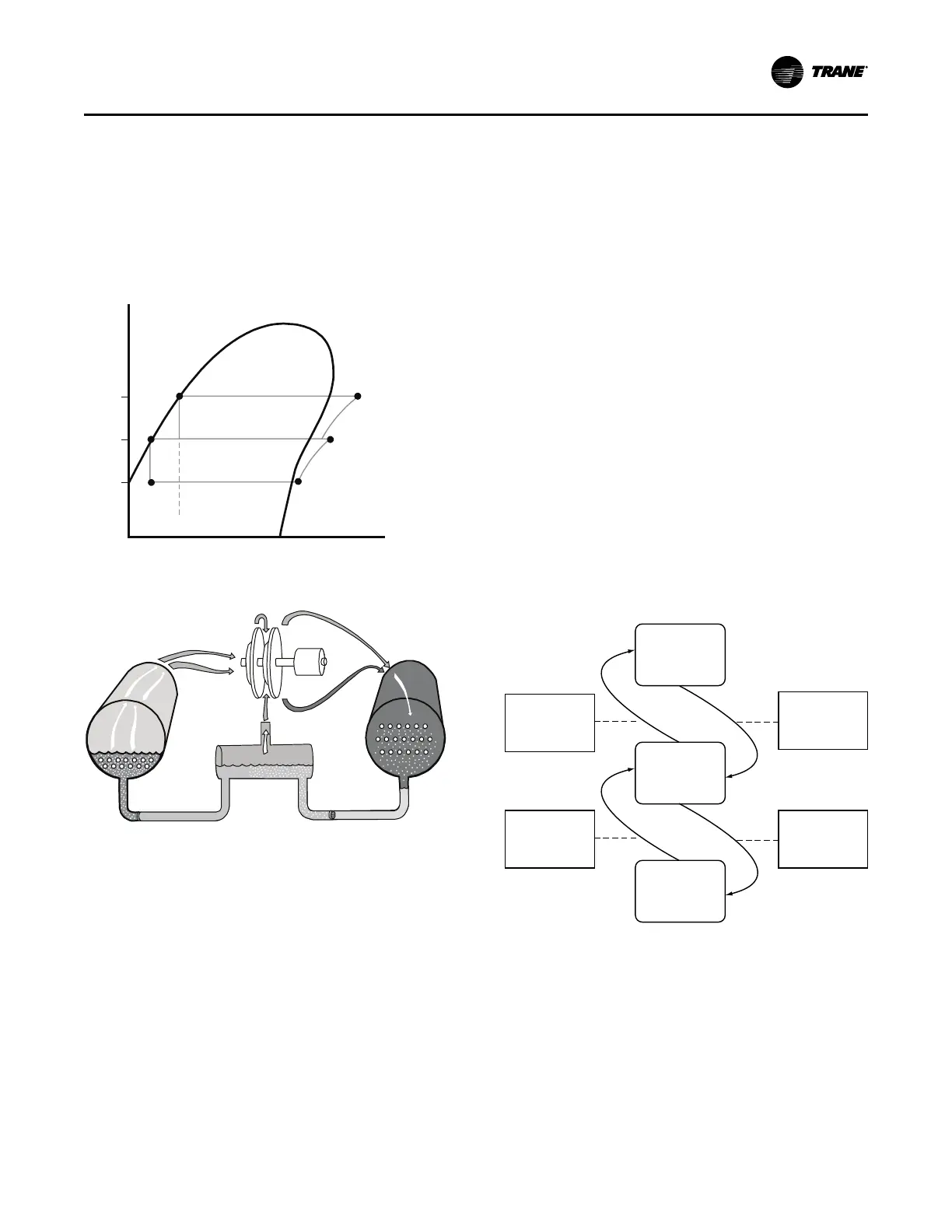

Figure 52. Refrigerant flow, 2-stage

Duplex Compressor Sequencing

Four methods (two fixed-sequence methods, a balanced

start and hour’s method, and a no-staging method) are

provided for order of a compressor sequencing on

Duplex™ CenTraVac™ chillers. The desired method is

selectable at startup via the service tool. The application

can decide to either balance the wear burden among the

unit’s compressors, to start the most efficient compressor,

or to simultaneously start and stop both compressors to

minimize startup pull down time. Each method has specific

applications were it can be used advantageously. If one

compressor is locked out, in restart inhibit, or generally not

ready to start, the available compressor will be started.

Note: The following description assumes Compressor 1 is

the downstream compressor.

Fixed Sequence – Compressor 1 /

Compressor 2 (Default Mode)

If the chiller is in the Auto mode and all interlocks have

been satisfied, Compressor 1 will be started based on the

leaving water temperature rising above the “Differential to

Start” setting. Compressor 2 will stage on when the overall

chiller average capacity exceeds stage-on load point for

30 seconds. The stage-on load point is adjustable (via

service tool) up to 50 percent.

The default is 40 percent which means that a single

compressor would have to load to 80 percent (the average

would be 40 percent) before the second compressor starts.

Both compressors will run until chiller average capacity

drops below stage-off load point for 30 seconds. The stage-

off load point is also adjustable (via service tool) (default =

30 percent, range from 0 to 50 percent). Compressor 2 will

be shutdown and Compressor 1 will run until water

temperature drops below the differential to stop. Before

shutting down, Compressor 2 will be unloaded and

Compressor 1 will be loaded to maintain the same average

capacity command. When running chilled water

temperature at selected conditions, the downstream

compressor usually will be the most efficient compressor to

operate at part load because compressors on Duplex™

CenTraVac™ chillers are not sized exactly the same.

Figure 53. Duplex™ chiller sequence of operation:

lead 1 / lag 2

Auto

Evap LWT Falls

Below

Differential to

Stop

Evap

LWT Rises

Above

Differential to

Start

Running

(Circuit 1)

Running

(Circuit

1 and 2)

Chiller Capacity

Less than 30%

(No Time Delay)

Compressor A

Capacity Greater

than 80%

(No Time Delay)

Fixed Sequence – Compressor 2 /

Compressor 1

If the chiller is in the Auto mode and all interlocks have

been satisfied, Compressor 2 will be started based on the

leaving water temperature rising above the “Differential to

Start” setting. Compressor 1 will stage on when the overall

chiller average capacity exceeds stage on load point for

30 seconds. The stage-on load point is adjustable up to

50 percent.

Operating Principles

Loading...

Loading...