28

CDHH-SVX003C-EN

Strainers

NOTICE

Water Borne Debris!

To prevent components damage, pipe strainers must

be installed in the water supplies to protect

components from water borne debris. Trane is not

responsible for equipment-only-damage caused by

water borne debris.

Install a strainer in the entering side of each piping circuit to

avoid possible tube plugging in the chiller with debris.

Required Flow-Sensing Devices

The ifm efector® flow detection controller and sensor (refer

to “Water Flow Detection Controller and Sensor – ifm

efector,” p. 28) is used to verify evaporator and condenser

water flows.

If a customer-supplied flow sensing device is used to

ensure adequate chiller flow protection, refer to the wiring

diagrams that shipped with the unit for specific electrical

connections.

Be sure to follow the manufacturer’s recommendations for

device selection and installation.

Water Flow Detection Controller and

Sensor – ifm efector

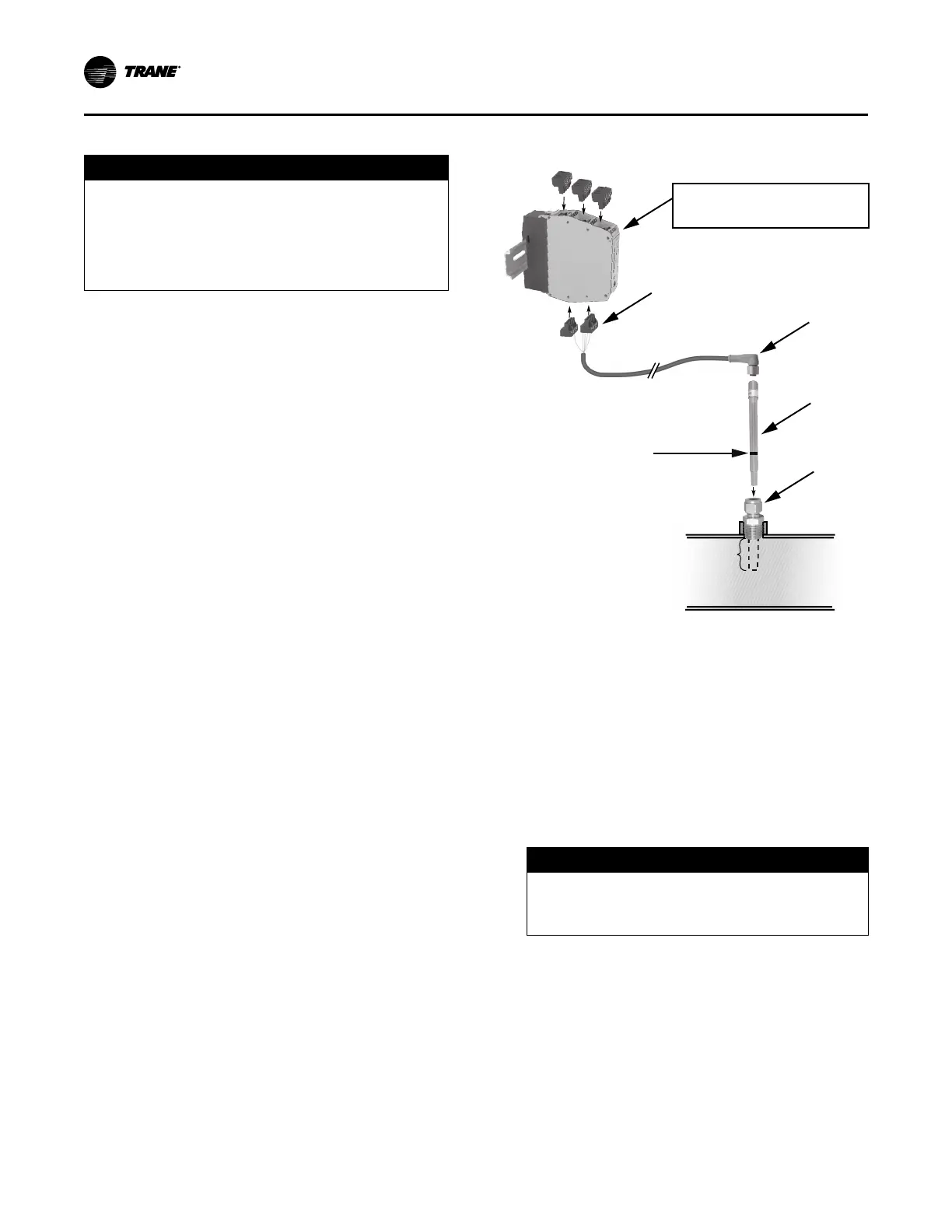

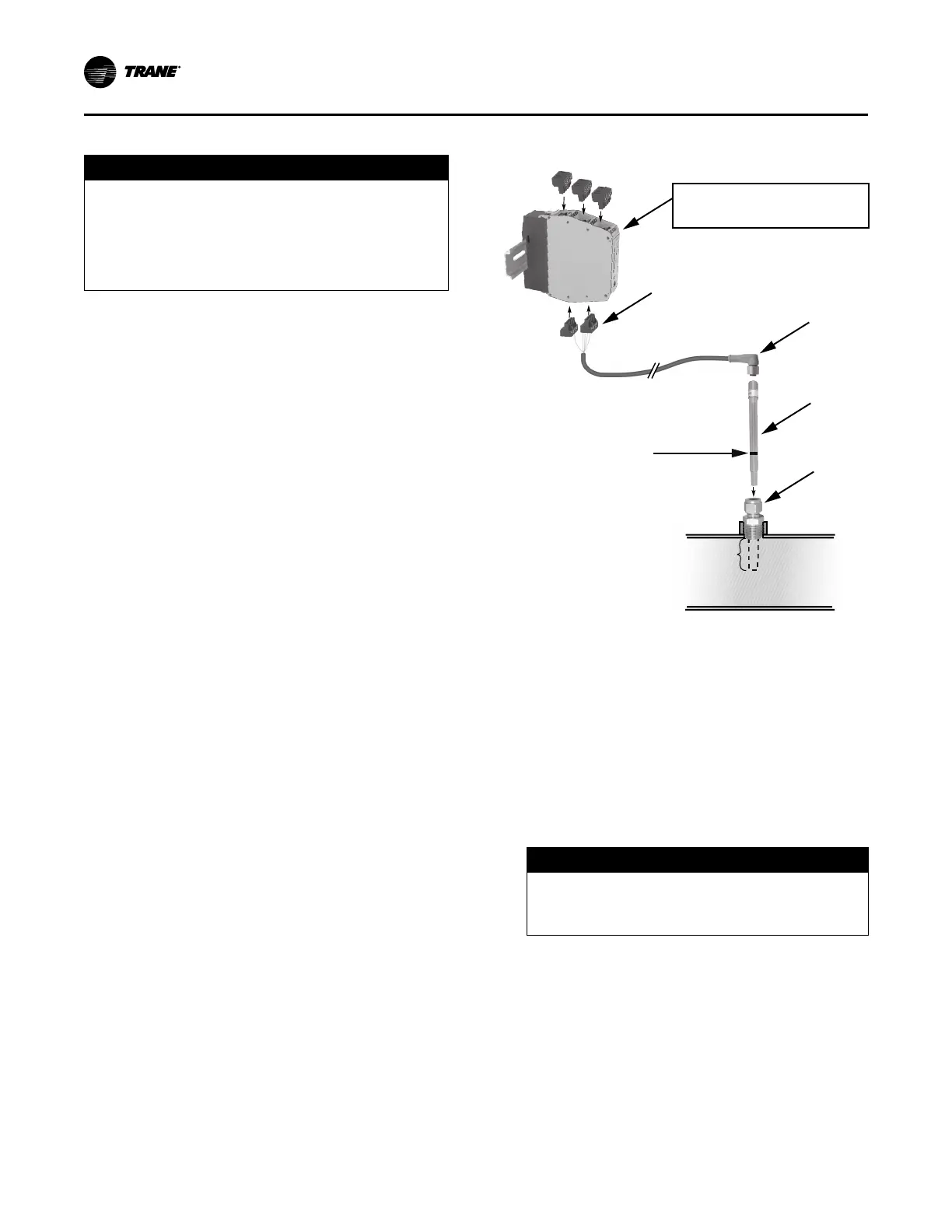

Important: Before installing the ifm efector® flow detection

controller and sensor, use a marker to draw a

line on the probe at 3.5 in. (8.9 cm) from the

end of the probe. Do NOT insert more than 3.5

in. (8.9 cm) of the probe length into the pipe.

Refer to the following figure.

Figure 13. Installation of ifm efector flow detection

controller and sensor

If factory-provided,

located in control panel.

Do NOT insert more than

3.5 in. (8.9 cm) of the

probe length into the pipe.

4

3

2

1

Use a marker to draw a line

on the probe at 3.5 in. (8.9 cm)

from the probe end.

1. Mount the 1/2-in. NPT adapter in a horizontal or vertical

section of pipe. The maximum distance from the control

panel must not exceed 29.5 ft (9 m) (see item labeled

“1” in the preceding figure). Allow at least five pipe

diameters straight run of pipe upstream of the sensor

location, and three pipe diameters straight run of pipe

downstream of the sensor location.

Note: In the case of a horizontal pipe, mounting the

sensor in the side of the pipe is preferred. In the

case of a vertical pipe, mounting the sensor in a

place where the water flows upwards is

preferred.

NOTICE

Overtightening!

Do not exceed torque specifications as it could

result in equipment damage.

2. Insert the flow sensor probe (see item labeled “2” in the

preceding figure) through the 1/2-in. NPT adapter so

that 3 to 3.5 in. (7.6 to 8.9 cm) of the probe’s length

extends into the pipe. Tighten the 1/2-in. NPT adapter

as needed to prevent leakage and keep the probe from

backing out under pressure. Do NOT exceed 40 ft·lb

(54.2 N·m) of torque on the fitting. Sensor damage

can occur if it is overtightened.

Installation: Water Piping

Loading...

Loading...