CDHH-SVX003C-EN

91

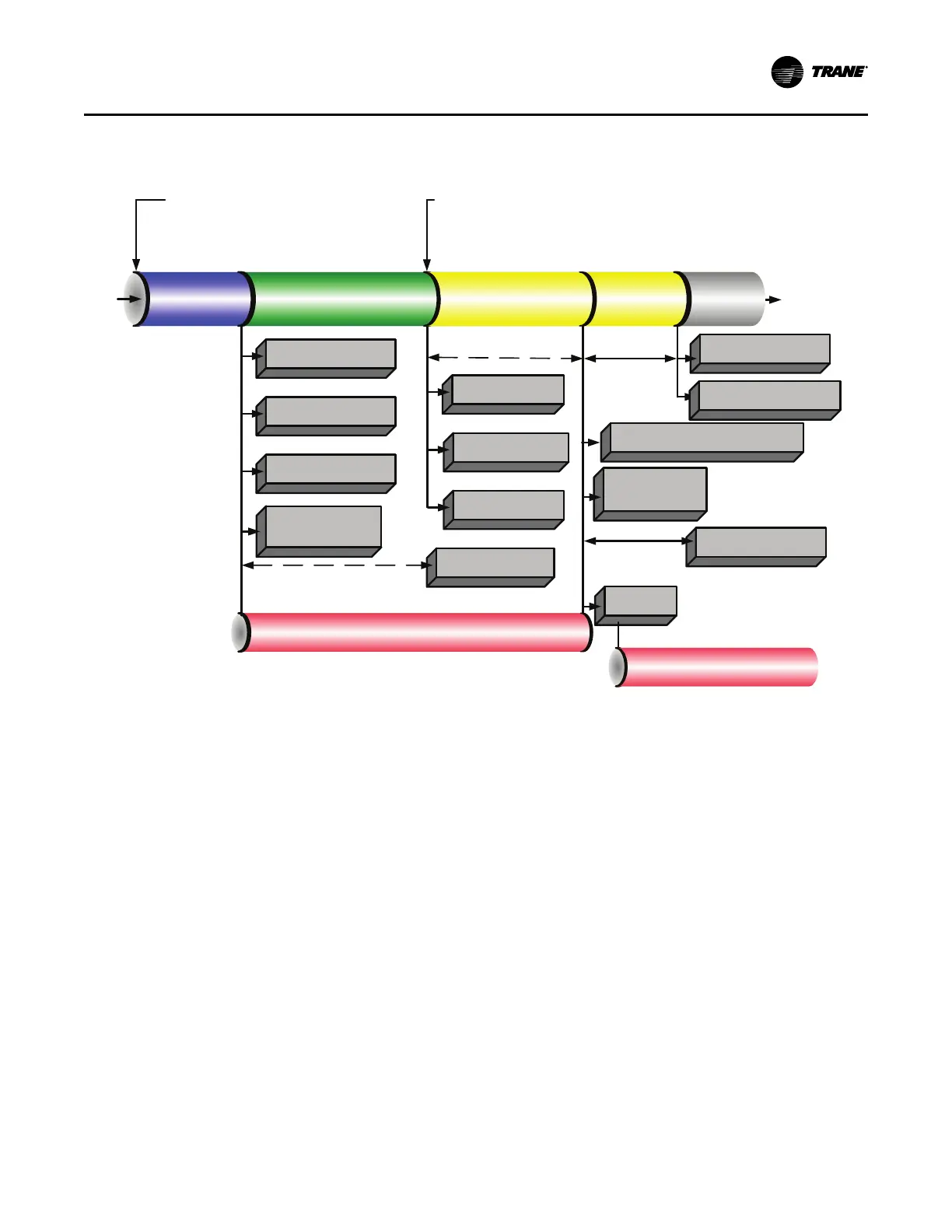

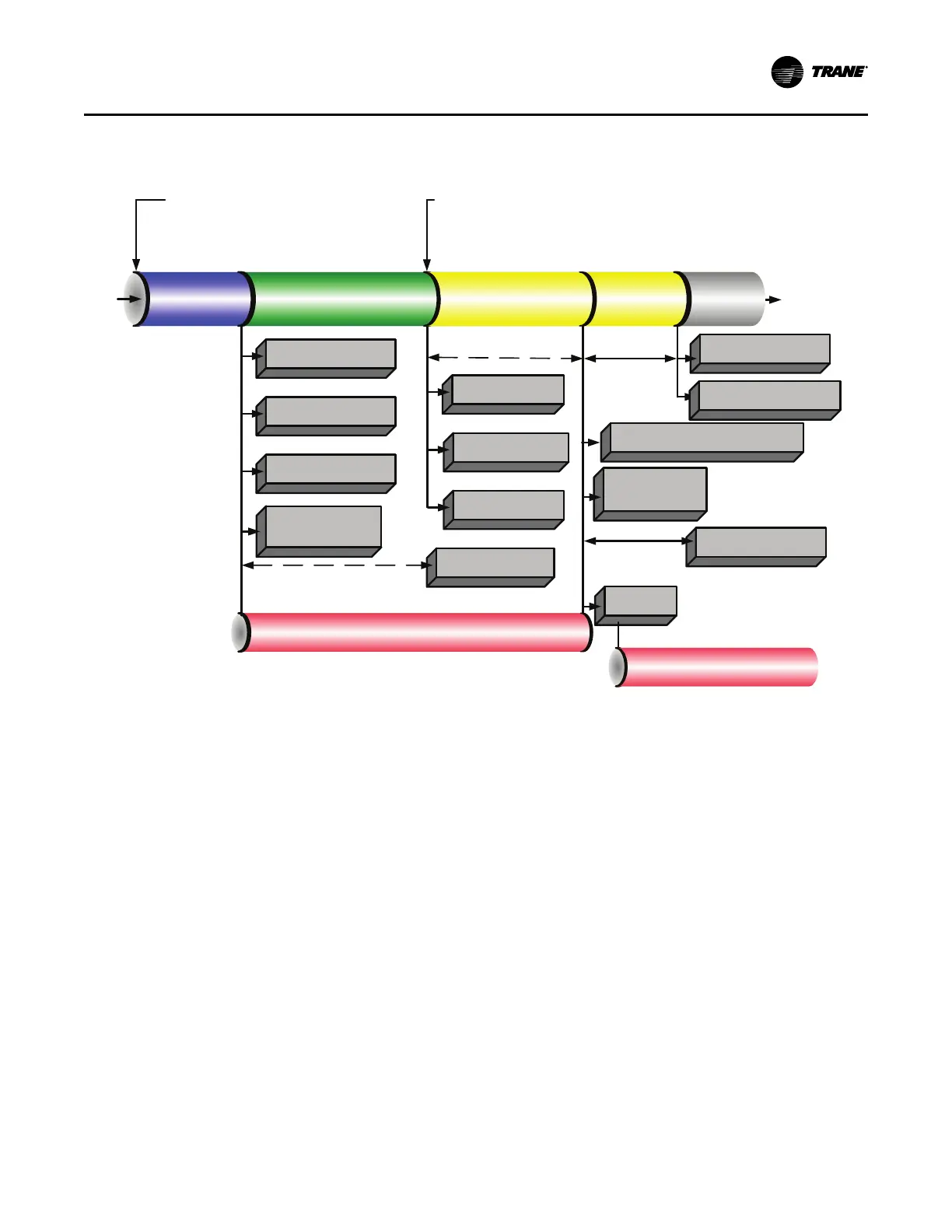

Figure 65. Sequence of operation: ice building: stopped to ice to ice building complete

Auto

Evap Entering

Water Temp Falls

Below the Ice

Termination

Setpoint

Run Inhibit

(Ice Building

Complete)

Running

(Ice Building)

Open IGV at Max Rate /

Max AFD Frequency

Close IGV /Min AFD

Frequency

Enforce All Limits and Running Mode Diagnostics

Ice Building Command:

1. Front Panel

2. Tracer

3. External Input

Energize Ice Building

Relay

Ignore Softloading and

Set CLS = 100%

De-Energize Ice Building

Relay

De-Energize Head Relief

Request Relay

Close IGV

(0-50 Seconds)

Starting

Compressor

Shutting

Down

Energize Head Relief

Request Relay

Head Relief Request Relay

Delay (1 to 60 Mins)

Preparing to

Shut Down

De-Energize Oil Pump

De-Energize

Compressor

Post Lube (3

Minutes)

Ignore Evap Pump Off

Delay Time For Ice

Building

De-Energize Evaporator

Water Pump Relay

De-Energize

Condenser

Water Pump Relay

Confirm No Compressor Currents

Within 8 Seconds

Run

Inhibit

Hold position of Oil Vent Line Valve

(CVHH ONLY)

Open Oil Vent Line Valve

(CVHH ONLY)

Begin Oil Vent Line

Valve low limit venting

(CVHH ONLY)

Hot Water Control

Occasionally, CenTraVac™ chillers are selected to provide

heating as a primary mission. With hot water temperature

control, the chiller can be used as a heating source or

cooling source. This feature provides greater application

flexibility. In this case, the operator selects a hot water

temperature and the chiller capacity is modulated to

maintain the hot water setpoint. Heating is the primary

mission and cooling is a waste product or is a secondary

mission. This type of operation requires an endless source

of evaporator load (heat), such as well or lake water. The

chiller has only one condenser.

Note: Hot Water Temperature Control mode does NOT

convert the chiller to a heat pump. Heat pump refers

to the capability to change from a cooling-driven

application to a heating-driven application by

changing the refrigerant path on the chiller. This is

impractical for centrifugal chillers as it would be

much easier to switch over the water side.

This is NOT heat recovery. Although this feature could be

used to recover heat in some form, a heat recovery unit has

a second heat exchanger on the condenser side.

The Tracer

®

AdaptiView™ provides the Hot Water

Temperature Control mode as standard. The leaving

condenser water temperature is controlled to a hot water

setpoint between 80°F and 140°F (26.7°C and 60.0°C).

The leaving evaporator water temperature is left to drift to

satisfy the heating load of the condenser. In this

application, the evaporator is normally piped into a lake,

well, or other source of constant temperature water for the

purpose of extracting heat. In Hot Water Temperature

Control mode, all the limit modes and diagnostics operate

as in normal cooling with one exception: the leaving

condenser water temperature sensor is an MMR diagnostic

when in Hot Water Temperature Control mode. (It is an

informational warning in the Normal Cooling mode.)

In the Hot Water Temperature Control mode, the

differential-to-start and differential-to-stop setpoints are

used with respect to the hot water setpoint instead of with

the chilled water setpoint. The control panel provides a

separate entry at the Tracer

®

AdaptiView™ to set the hot

water setpoint; Tracer

®

AdaptiView™ is also able to set the

hot water setpoint. In the Hot Water mode, the external

chilled water setpoint is the external hot water setpoint; that

is, a single analog input is shared at the 1K6-J2-5 to 6

(ground).

An external binary input to select external Hot Water

Control mode is on the EXOP OPTIONAL module 1K8

terminals J2-3 to J2-4 (ground). Tracer

®

AdaptiView™ also

Start-up and Shutdown

Loading...

Loading...