34

CDHH-SVX003C-EN

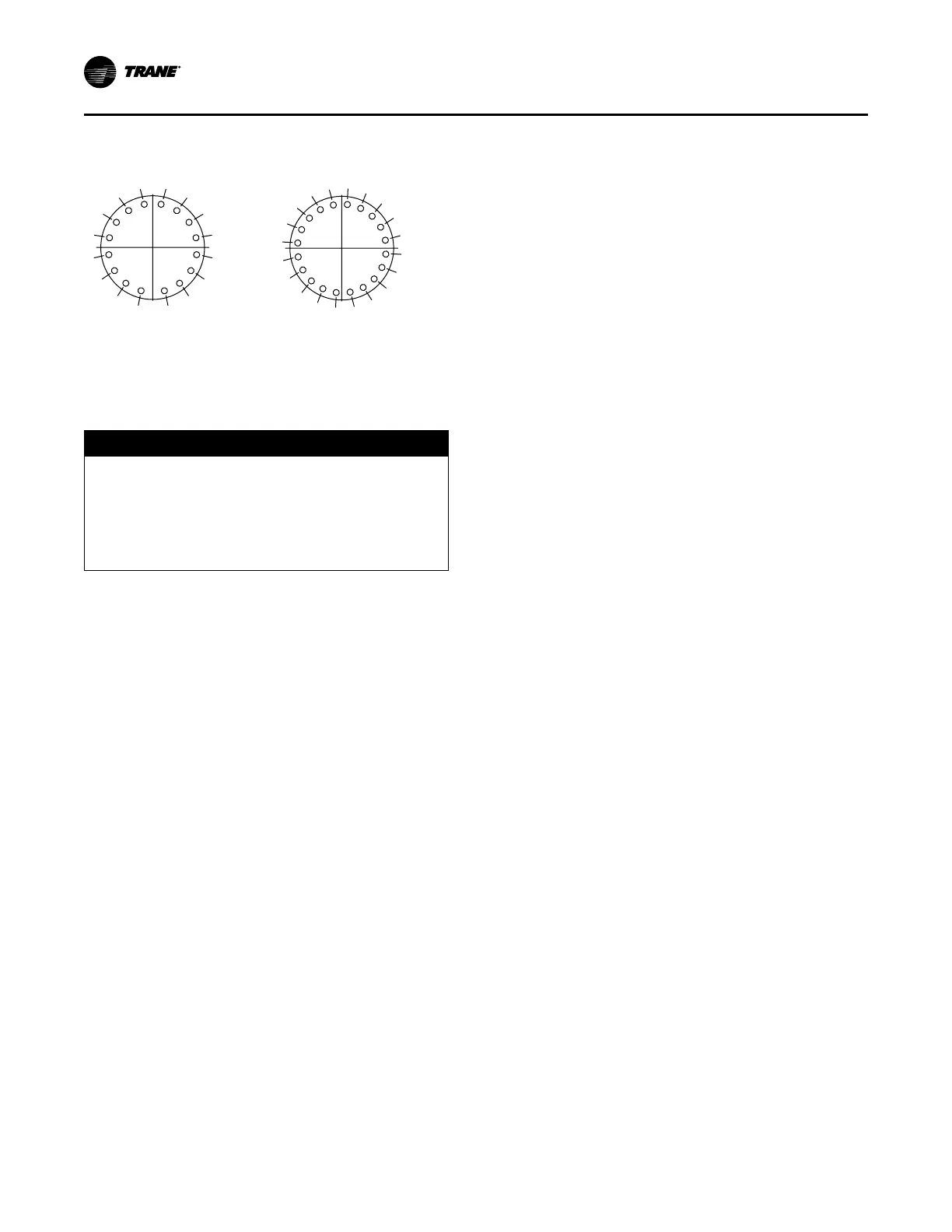

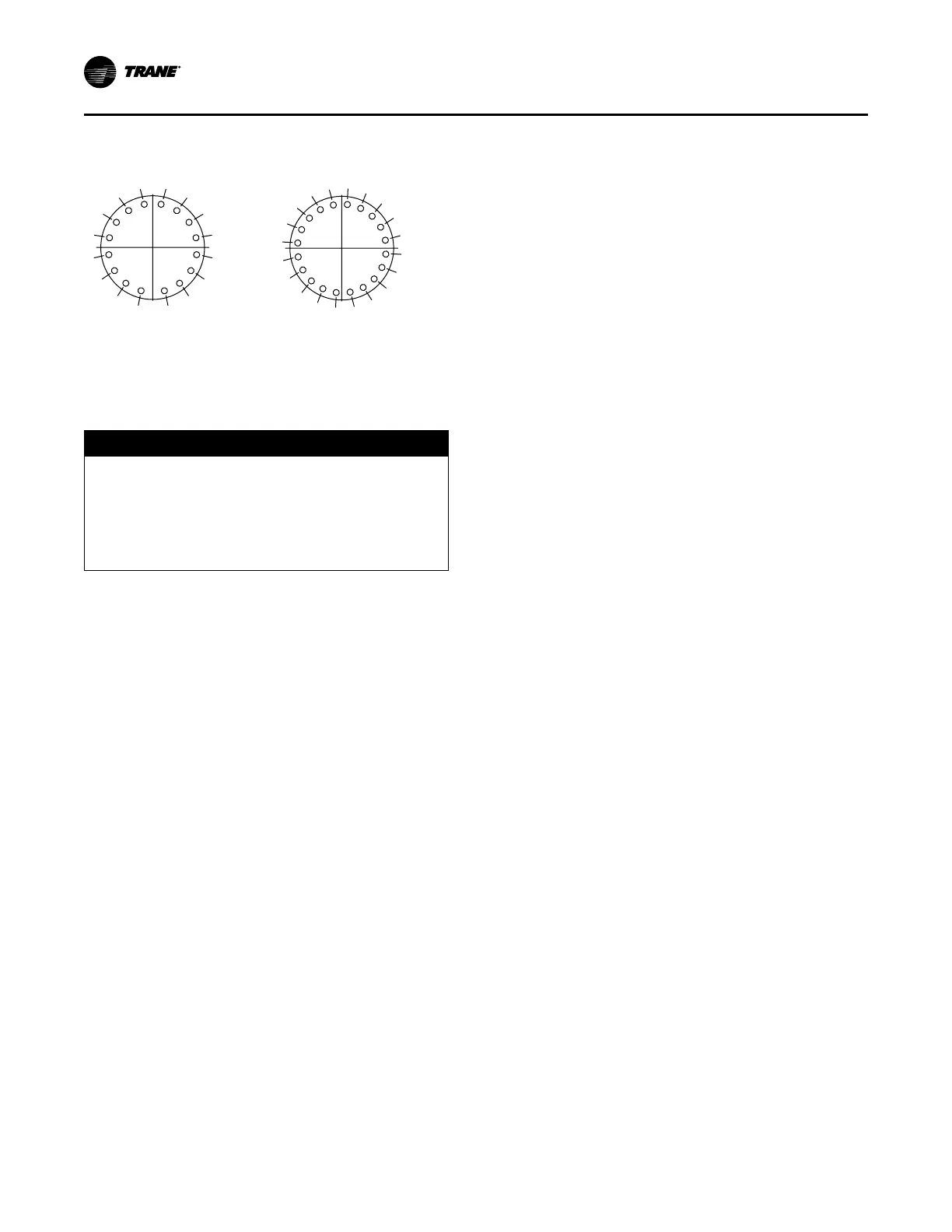

Figure 23. Flange screw tightening sequence (16 or

20 screws)

16 screws 20 screws

1 5

9

20

2

3

4

6

7

8

10

19

18

17

16

15

14

13

12

11

1

5

9

2

3

4

6

7

8

10

16

15

14

13

12

11

Pressure Testing Waterside

Piping

NOTICE

Equipment Damage!

Failure to follow these instructions could result in

equipment damage.

Do not over pressurize the system or exceed design

pressure. Always perform a hydro pressure test with

water present in piping and waterboxes.

Waterside design pressure is either 150 psig

(1034.2 kPaG) or 300 psig (2068.4 kPaG); refer to unit

nameplate or to submittal documentation.

Eddy Current Testing

Trane recommends conducting an eddy current inspection

of the condenser and evaporator tubes in water-cooled

chillers every three years. Eddy current tests are intended

to identify defects on or within the walls of heat exchanger

tubing that could lead to in-service tube failures. Eddy

current tests conducted before a chiller is put into service

are considered “baseline” eddy current tests, and are

intended to establish a reference point to aid in the

interpretation of future eddy current test reports. Many of

the anomalies that can be found through eddy current

testing have no impact on tube life or performance, while

others are severe enough to justify removing the affected

tube from service. Ask your sales account manager for a

copy of the engineering bulletin (CTV-PRB024*-EN) for

clarification of the role of eddy current testing in chiller

maintenance by providing information about eddy current

technology and heat exchanger tubing.

Installation: Water Piping

Loading...

Loading...