CDHH-SVX003C-EN

65

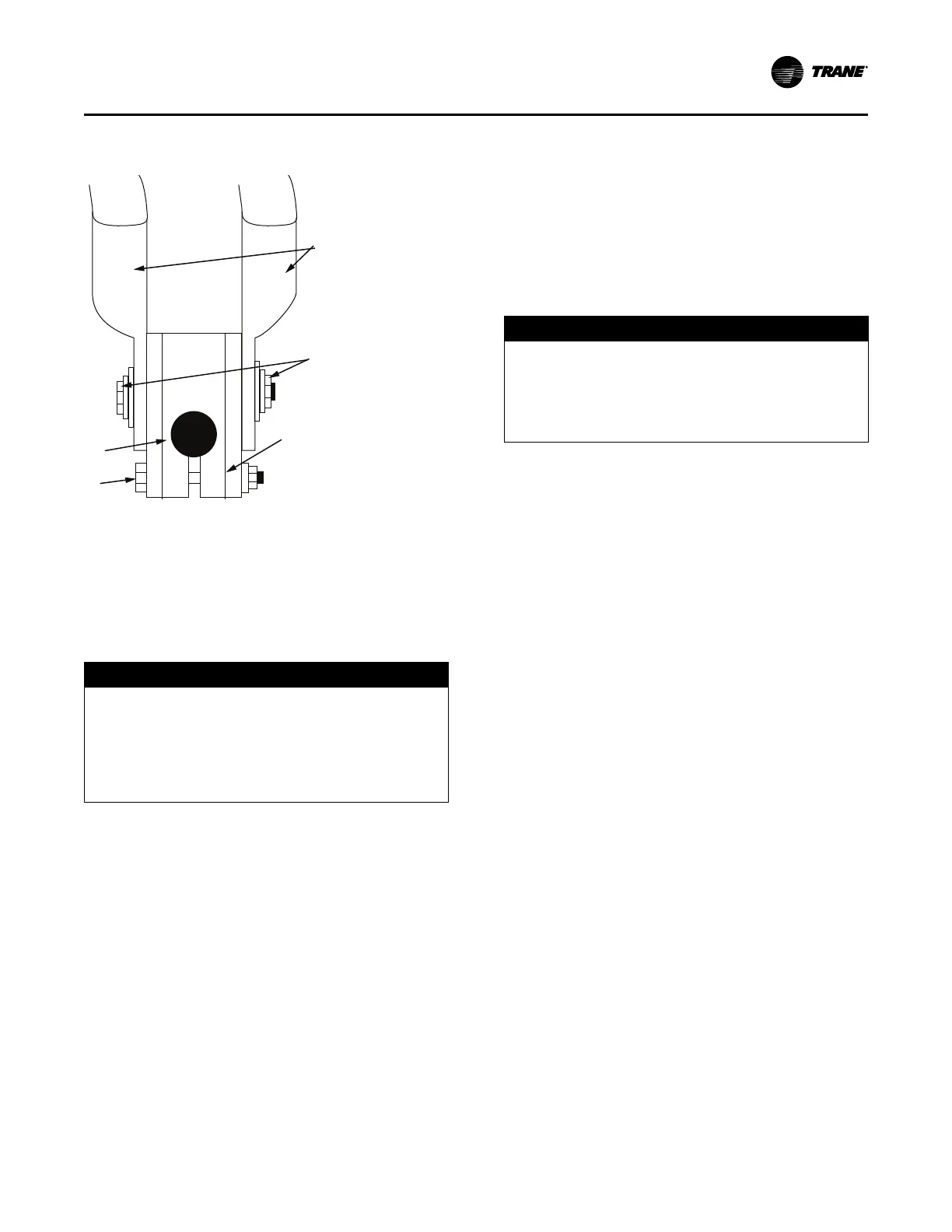

Figure 45. Terminal stud, clamp, and lug assembly

(600V and below)

1. Belleville washer

2. Terminal lugs

3. Terminal clamp

4. Motor terminal stud

5. Terminal mounting bolt

Bus Bars

NOTICE

Component Damage!

Failure to follow instructions below could cause an

electrical short which could result in component

damage.

Remove debris from inside the CPTR option

enclosure panel before turning the power on.

Bus bars and extra nuts are available as a Trane option.

Install the bus bars between the motor terminals when

using a starter that is:

• A low-voltage Adaptive Frequency™ Drive (AFD)

• Across-the-line

• Primary reactor/resistor

• Autotransformer

• Customer-supplied

Connect T1 to T6, T2 to T4, and T3 to T5.

Note: Bus bars are not needed in medium-voltage or high-

voltage applications since only three terminals are

used in the motor and starter.

Starter to Control Panel Wiring

The unit submittal includes the field wiring connection

diagram and the starter-to-control-panel connection

diagram (showing the electrical connections required

between the remote-mounted starter and the control

panel).

Note: Install separate conduit into the low voltage (30 volts)

section of the control panel.

When sizing and installing the electrical conductors for

these circuits, follow the guidelines listed. Use 14 AWG for

120V control circuits unless otherwise specified. For AWG/

MCM equivalents in mm

2

, refer to the table in “Electrical

Requirements,” p. 53.

NOTICE

Adaptive Frequency Drive (AFD)/Starter

Component Damage!

Failure to remove debris from inside the AFD/starter

panel could result in an electrical short and could

cause serious AFD/starter component damage.

Important: Maintain at least 6 in. (16 cm) between low-

voltage (less than 30V) and high-voltage

circuits. Failure to do so could result in

electrical noise that may distort the signals

carried by the low-voltage wiring, including the

inter-processor communication (IPC) wiring.

To wire the starter to the control panel, use these

guidelines:

• If the starter enclosure must be cut to provide electrical

access, exercise care to prevent debris from falling

inside the enclosure. Do NOT cut the Adaptive

Frequency™ Drive (AFD) enclosure.

• Use only shielded, twisted-pair wiring for the inter-

processsor communication (IPC) circuit between the

starter and the control panel on remote-mounted

starters.

Note: Recommended wire is Beldon Type 8760,

18 AWG for runs up to 1000 ft (304.8 m). For

AWG/MCM equivalents in mm

2

, refer to the

table in “Electrical Requirements,” p. 53. The

polarity of the IPC wiring is critical for proper

operation.

• Separate low-voltage (less than 30V; refer to the table

in “Trane-supplied Remote Starter Wiring,” p. 54)

wiring from the 115V wiring by running each in its own

conduit.

• When routing the IPC circuit out of the starter

enclosure, ensure that it is at least 6 in. (16 cm) from all

wires carrying a higher voltage.

Power Supply Wiring

Loading...

Loading...