CDHH-SVX003C-EN

15

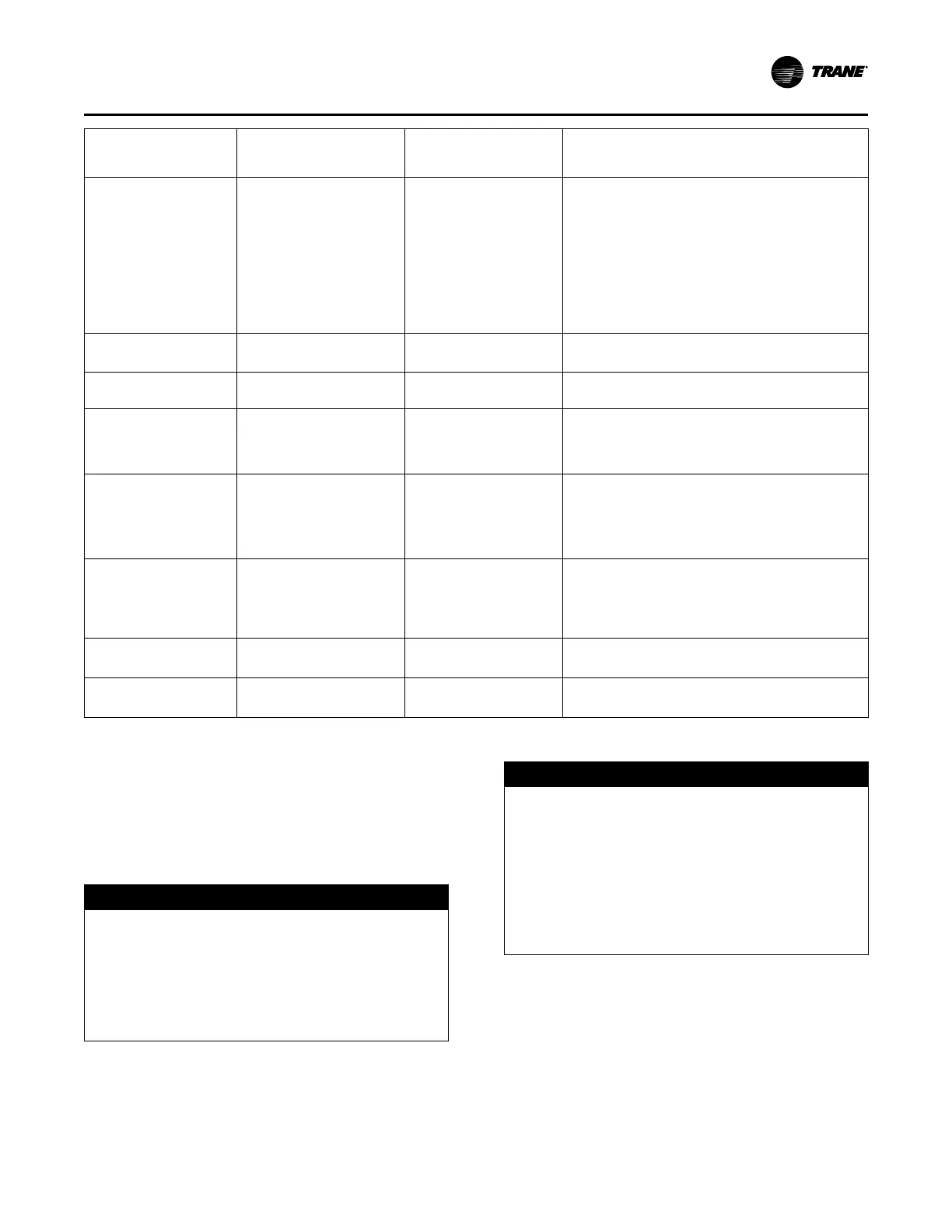

Type of Requirement

Trane Supplied

Trane Installed

Trane Supplied

Field Installed

Field Supplied

Field Installed

Water piping

Flow sensing devices

(may be field supplied)

• Taps for flow sensing devices

• Taps for thermometers and gauges

• Thermometers

• Strainers (as required)

• Water flow pressure gauges

• Isolation and balancing valves in water piping

• Vents and drain on waterbox valves (one each per pass)

• Pressure relief valves (for waterboxes as required)

Relief

• Rupture disk assembly

• RuptureGuard™ (optional)

Vent line and flexible connector and vent line from rupture disk

to atmosphere

Insulation

Insulation (optional)

• Insulation

• Chiller feet insulation

Water Piping Connection

Components

Flanged (optional)Welded on

flange for 300 psig (2068.4 kPaG)

waterboxes

Flanged (optional)

Victaulic® to flange adapter for

150 psig (1034.2 kPaG)

waterboxes

Victaulic®

• Victaulic® coupling for 150 psig (1034.2 kPaG) and

300 psig (2068.4 kPaG) waterboxes

• Fasteners for flanged-type connections (optional)

Other Materials

• Trace gas (1 lb [0.45 kg] maximum per machine as

needed to perform leak testing)

• Material and equipment to perform leak testing

• Dry nitrogen (8 psig [55.2 kPaG] maximum per machine

as needed)

“Appendix B: Chiller Installation

Completion and Request for

Trane Service,” p. 116 (CTV-

ADF001*-EN; refer to

“Appendix A: Forms and Check

Sheets,” p. 115)

To be completed by installing contractor prior to contacting

Trane for start-up

Chiller start-up commissioning

(a)

Trane, or an agent of Trane

specifically authorized to perform

start-up of Trane® products

Post-commissioning transport

of empty refrigerant containers

for return or recycling

Move empty refrigerant containers to an easily accessible point

of loading

(a)

Start-up must be performed by Trane or an agent of Trane specifically authorized to perform start-up and warranty of Trane® products. Contractor shall provide Trane (or an

agent of Trane specifically authorized to perform start-up) with notice of the scheduled start-up at least two weeks prior to the scheduled start-up.

Storage Requirements

Note: If the chiller is stored outdoors for any amount of time,

do NOT remove ANY shipping coverings.

Protect the chiller from the elements and protect

against freezing, especially if any shipping

materials have been removed.

NOTICE

Equipment Damage!

Failure to protect the unit from freezing could result in

equipment damage.

If fluid has been added to the piping, the unit must be

protected from freezing. Freeze damage from an

unheated equipment room is not the Trane company's

responsibility. These are indoor units.

NOTICE

Insulation Damage!

Failure to follow these instructions could result in

insulation damage.

To prevent damage to factory installed insulation:

• Do not allow the insulation to be exposed to

excessive sunlight. Store indoors or cover with

canvas to prevent exposure.

• Do not use thinners and solvents or other types of

paint. Use only water base latex.

Pre-Installation

Loading...

Loading...