78

CDHH-SVX003C-EN

The default is 40 percent which means that a single

compressor would have to load to 80 percent (the average

would be 40 percent) before the second compressor starts.

Both compressors will run until chiller average capacity

drops below stage-off load point for 30 seconds. The stage-

off load point is also adjustable. Compressor 1 will be

shutdown and Compressor 2 will run until water

temperature drops below the differential to stop. Before

shutting down, Compressor 1 will be unloaded and

Compressor 2 will be loaded to maintain the same average

capacity command. If chilled water reset is used, the

upstream compressor usually will be the most efficient

compressor to operate at part load. If the leaving water

temperature is reset and the chiller only needs one

compressor, then the upstream compressor would be

running closer to its selection point and will be the most

efficient compressor to operate.

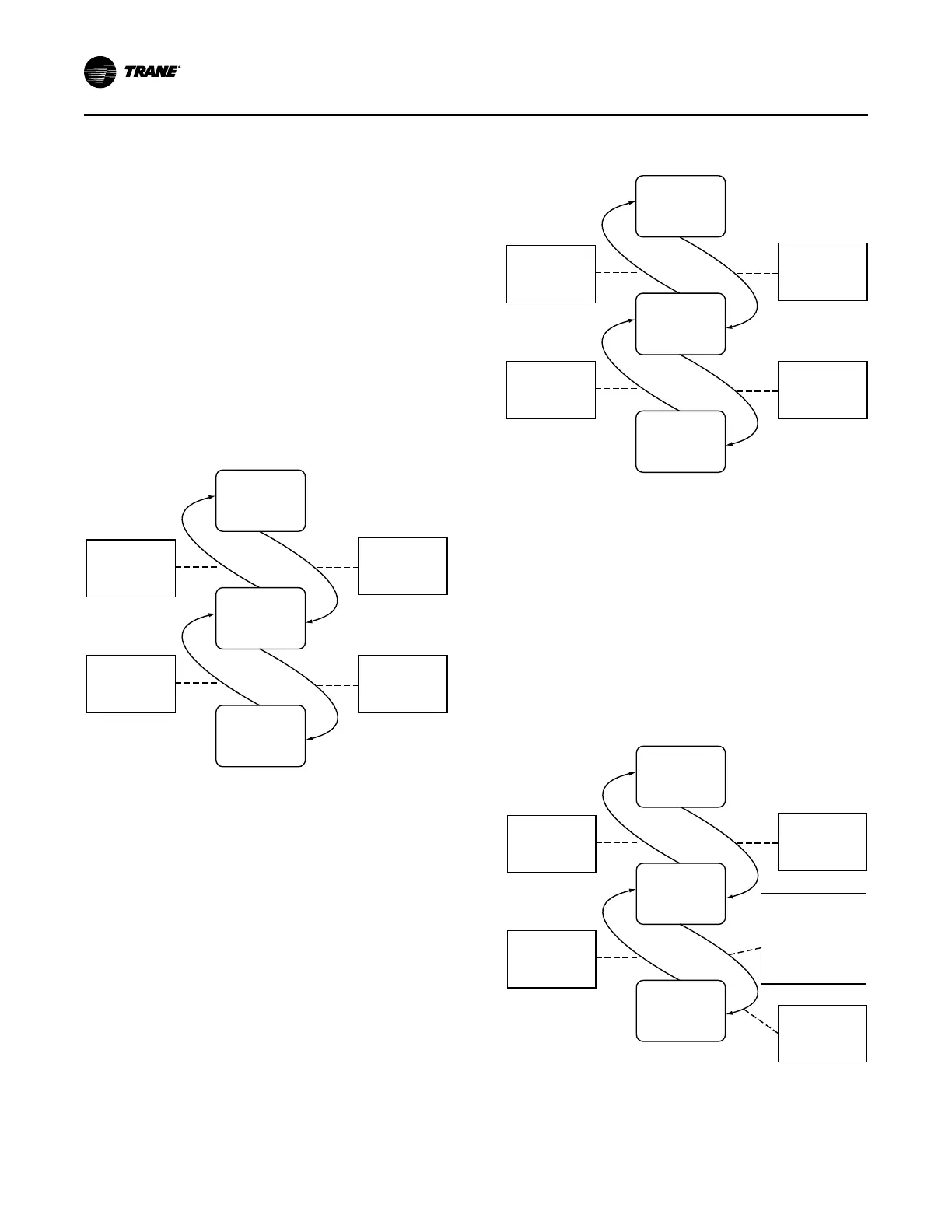

Figure 54. Duplex™ chiller sequence of operation:

lead 2 / lag 1

Auto

Evap LWT Falls

Below

Differential to

Stop

Evap LWT Rises

Above Diff to

Start (Start Cprsr

with Fewest

Starts and Hours)

Running

(Circuit 2)

Running

(Circuit

1 and 2)

Chiller Capacity

Less than 30%

(De-Energize

Cprsr with Most

Starts and Hours)

Single Comp

Capacity Greater

than 80% (No

Time Delay)

Sequencing – Balanced Starts and Hours

When desired to balance the wear between the

compressors, this method will extend the time between

maintenance on the lead compressor. When balanced

starts and hours is selected, the compressor with the

fewest starts will start. If that compressor is unavailable to

start due to a circuit lockout (including restart inhibit) or a

circuit diagnostic, then the other compressor will be started.

The second compressor will stage on when chiller capacity

exceeds the stage-on load point for 30 seconds. When

chiller capacity falls below stage-off load point for

30 seconds, the compressor with the most hours will be

shut off.

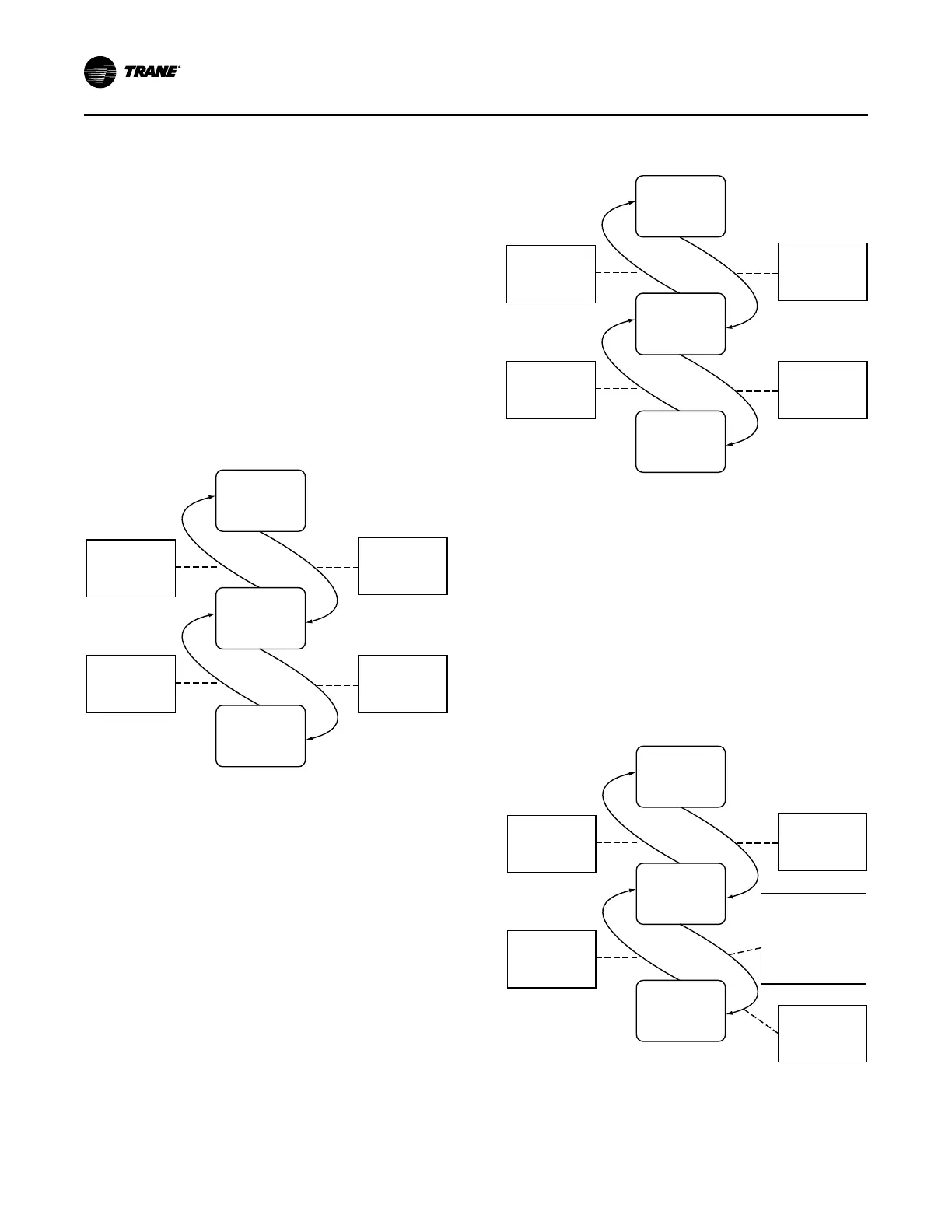

Figure 55. Duplex™ chiller sequence of operation:

equalize starts and hours

Auto

Evap LWT Falls

Below

Differential to

Stop

Running

(Single Circuit)

Running

(Both Circuits)

Evap LWT Rises

Above

Differential to

Stop

Compressor A

Capacity Greater

than 80%

(No Time Delay)

Chiller Capacity

Less than 30%

(No Time Delay)

Chiller Start Initial Capacity Command

If the Chiller Start Initial Capacity Command is set greater

than the Staging On Boundary, both compressors will cycle

on similar to a Combined Staging Sequence and both

compressors will load up to the initial capacity command. If

there is a reduction in load, the lag compressor will shut off

based on the staging sequence chosen. The simultaneous

start feature only applies when both compressor are off.

This feature is intended to allow a Duplex™ CenTraVac™

chiller to start and load quickly for customers that require

quick restart after a power failure.

Figure 56. Duplex™ chiller sequence of operation:

ready to serve

Auto

Running

(Single Circuit)

Running

(Both Circuits)

Evap LWT Falls

Below

Differential to

Stop

Evap LWT Rises

Above

Differential to

Stop

Chiller Capacity

Greater than

Staging Off

Boundary

Setpoint

On Start, if Initial

Capacity Command

Greater than Staging

On Boundary, then

Start First

Compressor, and

Immediately Start

Second Compressor

Chiller Capacity

Greater than

Staging On

Boundary

Setpoint

Operating Principles

Loading...

Loading...