CDHH-SVX003C-EN

113

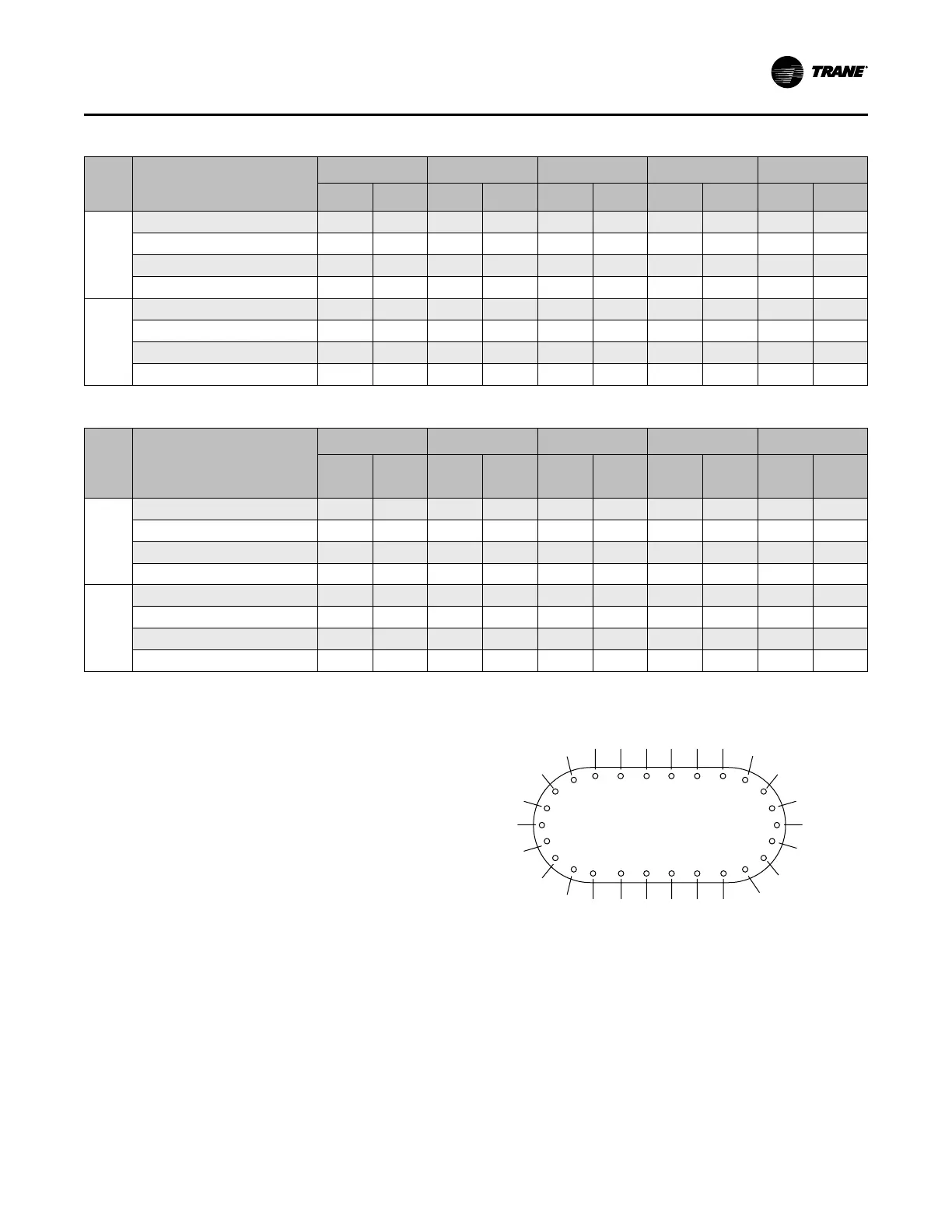

Table 29. Waterbox weights (IP units)

Shell

Size

Description

Non-Marine Plate Non-Marine Dome Marine Plate Cover

Marine Dome

Cover

Marine Waterbox

Weight

(lb)

Lifting

Hole (in.)

Weight

(lb)

Lifting

Hole (in.)

Weight

(lb)

Lifting

Hole (in.)

Weight

(lb)

Lifting

Hole (in.)

Weight

(lb)

Lifting

Hole (in.)

400

Evaporator, 150 psig

— — 652 0.469 1282 0.469 — — 2295 1.38

Evaporator, 300 psig

— — — — 1763 0.469 — — 2849 1.38

Condenser, 150 psig

— — 700 0.469 — 0.469 — — 1544 0.858

Condenser, 300 psig

— — — 0.469 1724 0.469 — — 2138 0.858

440

Evaporator, 150 psig

— — 802 0.469 1702 0.469 — — 3068 1.38

Evaporator, 300 psig

— — 1581 0.469 2476 0.469 — — 4137 1.38

Condenser, 150 psig

— — 763 0.469 — — 543 0.469 1598 0.858

Condenser, 300 psig

— — 1132 0.469 — — 708 0.469 1901 0.858

Table 30. Waterbox weights (SI units)

Shell

Size

Description

Non-Marine Plate Non-Marine Dome Marine Plate Cover

Marine Dome

Cover

Marine Waterbox

Weight

(kg)

Lifting

Hole

(mm)

Weight

(kg)

Lifting

Hole

(mm)

Weight

(kg)

Lifting

Hole

(mm)

Weight

(kg)

Lifting

Hole

(mm)

Weight

(kg)

Lifting

Hole

(mm)

400

Evaporator, 1034.2 kPaG

— — 295 11.9 581 11.9 — — 1041 35.1

Evaporator, 2068.4 kPaG

— — — — 799 11.9 — — 1292 35.1

Condenser, 1034.2 kPaG

— — 317 11.9 — 11.9 — — 700 21.8

Condenser, 2068.4 kPaG

— — — 11.9 782 11.9 — — 970 21.8

440

Evaporator, 1034.2 kPaG

— — 364 11.9 772 11.9 — — 1392 35.1

Evaporator, 2068.4 kPaG

— — 717 11.9 1123 11.9 — — 1876 35.1

Condenser, 1034.2 kPaG

— — 346 11.9 — — 246 11.9 724 21.8

Condenser, 2068.4 kPaG

— — 513 11.9 — — 321 11.9 862 21.8

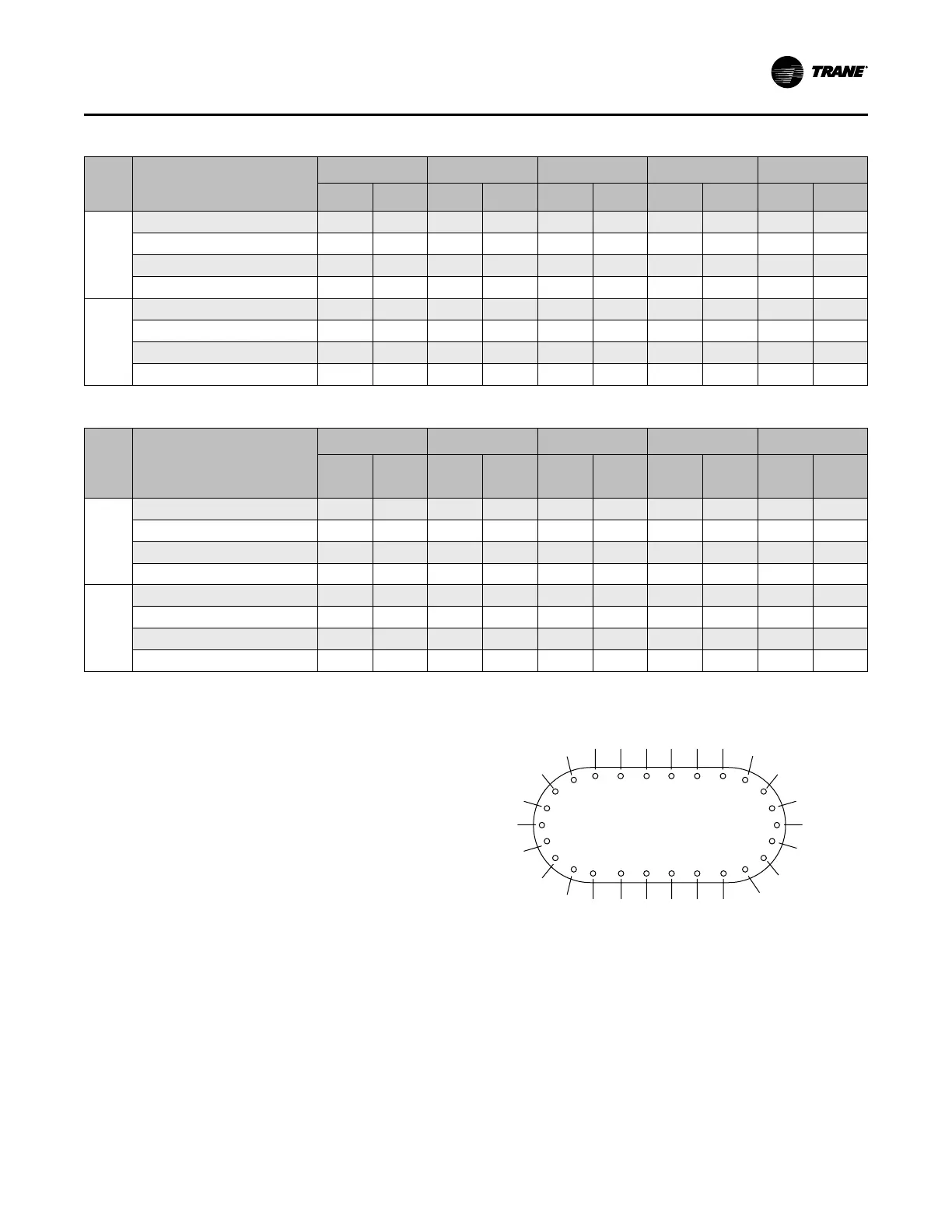

Screw-Tightening Sequence for

Waterboxes

Evaporator Waterbox Covers

Ensure that the waterbox head rests tightly against the

tube sheet, and then snugly tighten the screws in

sequential order as shown in the following figure. If

excessive tube sheet crown prevents the head from

contacting the tube sheet, tighten the screws located where

the greatest gaps occur. Be sure to use an equal number of

screw turns from side to side. Then, apply final torque to

each screw in sequential order.

Figure 74. Evaporator waterbox cover screw

tightening sequence

1

24

5

9

20

2

23

3

4

22

6

7

8

10

19

18

26

25

17

21

16

15

14

13

12

11

Condenser Waterbox Covers

Condenser waterbox covers use a similar procedure to that

which is used for the evaporator waterbox covers. Use a

crossing pattern as shown in the following figure.

Waterbox Removal and Installation

Loading...

Loading...