CDHH-SVX003C-EN

31

Field-provided isolation valves for the evaporator and

condenser water lines should be installed upstream and

downstream of the heat exchangers, and be installed far

enough away from the chiller to also provide practical

service isolation for flow sensing devices, field

thermometers, flexible connectors, and any removable pipe

spools.

Ensure that the evaporator water piping is clear; check it

after the chilled water pump is operated but before initial

chiller start-up. If any partial blockages exist, they can be

detected and removed to prevent possible tube damage

resulting from evaporator freeze-up or erosion.

For applications that include an “infinite source” or

“multiple-use” cooling condenser water supply, install a

valved bypass “leg” (optional) between the supply and

return pipes. This valved bypass allows the operator to

short-circuit water flow through the cooling condenser

when the supply water temperature is too low.

Note: System refrigerant pressure differential must be

maintained above 3 psid (20.7 kPaD) at all times.

Failure to do so could result in operating problems.

Water Piping Connections

All standard units use grooved-pipe connections. These

are grooved-end NSP (Victaulic® style) pipe connections.

Flanged connections are optional.

Piping joined using grooved type couplings, like all types of

piping systems, requires proper support to carry the weight

of pipes and equipment. The support methods used must

eliminate undue stresses on joints, piping, and other

components, allow movement where required, and provide

for any other special requirements (i.e., drainage, etc.).

Note: If needed, plug-type sensor extension cables are

available for purchase from Trane Parts Service.

These sensor extension cables may be necessary if

the waterboxes are changed or if the temperature

sensors are moved out into the unit piping for better

mixed temperature readings.

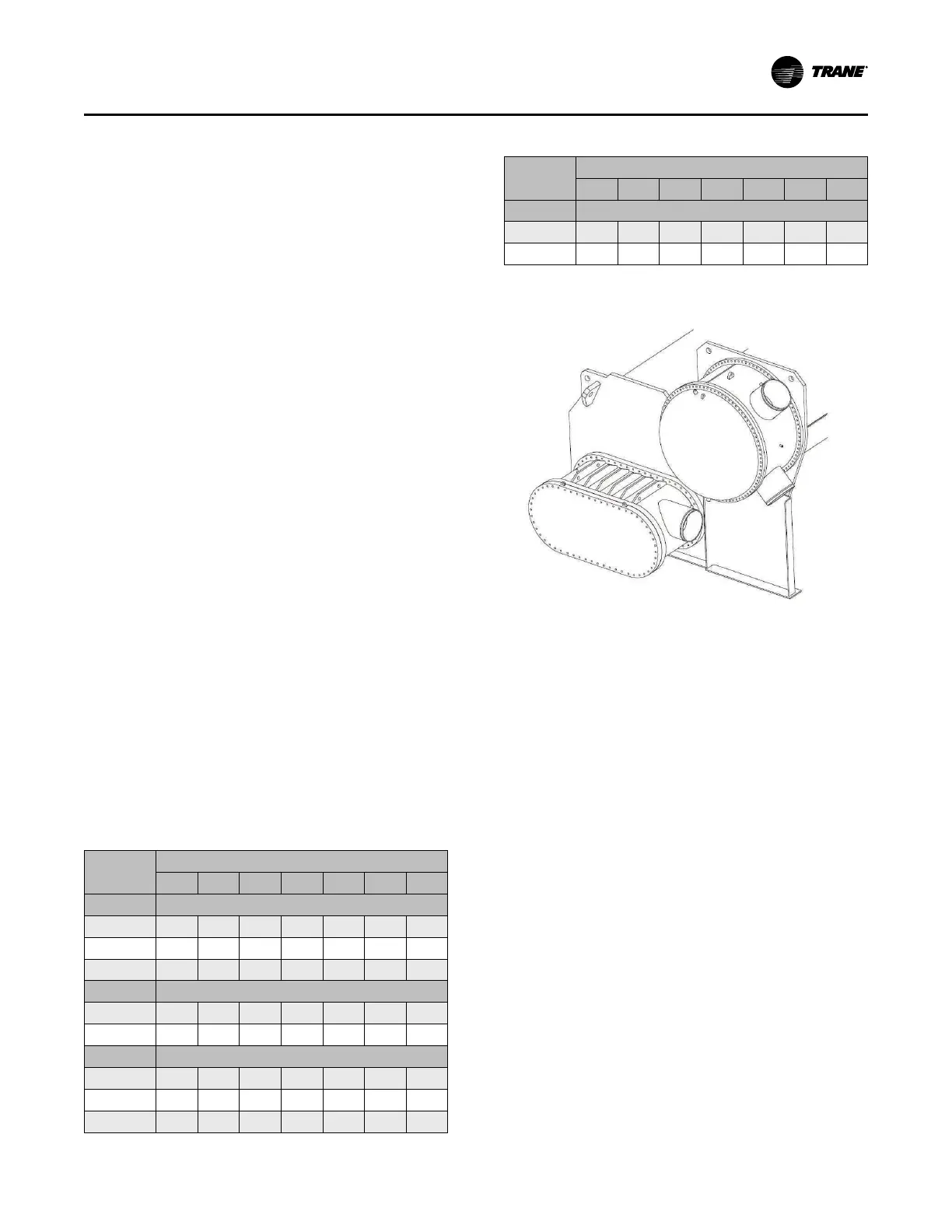

Table 10. Water connection pipe sizes

Water

Passes

Shell Size

100 130 160 200 220 400 440

Evaporator Nominal Pipe Size (in.)

1-Pass 12 12 14 16 20 16 20

2-Pass 10 10 12 14 14 — —

3-Pass 8 8 10 12 12 — —

Condenser

Nominal Pipe Size (in.)

1-Pass 12 14 — 16 24 — 24

2-Pass 10 12 — 14 14 — —

Evaporator Metric Pipe Size (mm)

1-Pass DN300 DN300 DN350 DN400 DN500 DN400 DN500

2-Pass DN250 DN250 DN300 DN350 DN350 — —

3-Pass DN200 DN200 DN250 DN300 DN300 — —

Table 10. Water connection pipe sizes (continued)

Water

Passes

Shell Size

100 130 160 200 220 400 440

Condenser

Metric Pipe Size (mm)

1-Pass DN300 DN350 — DN400 DN600 — DN600

2-Pass DN250 DN300 — DN350 DN350 — —

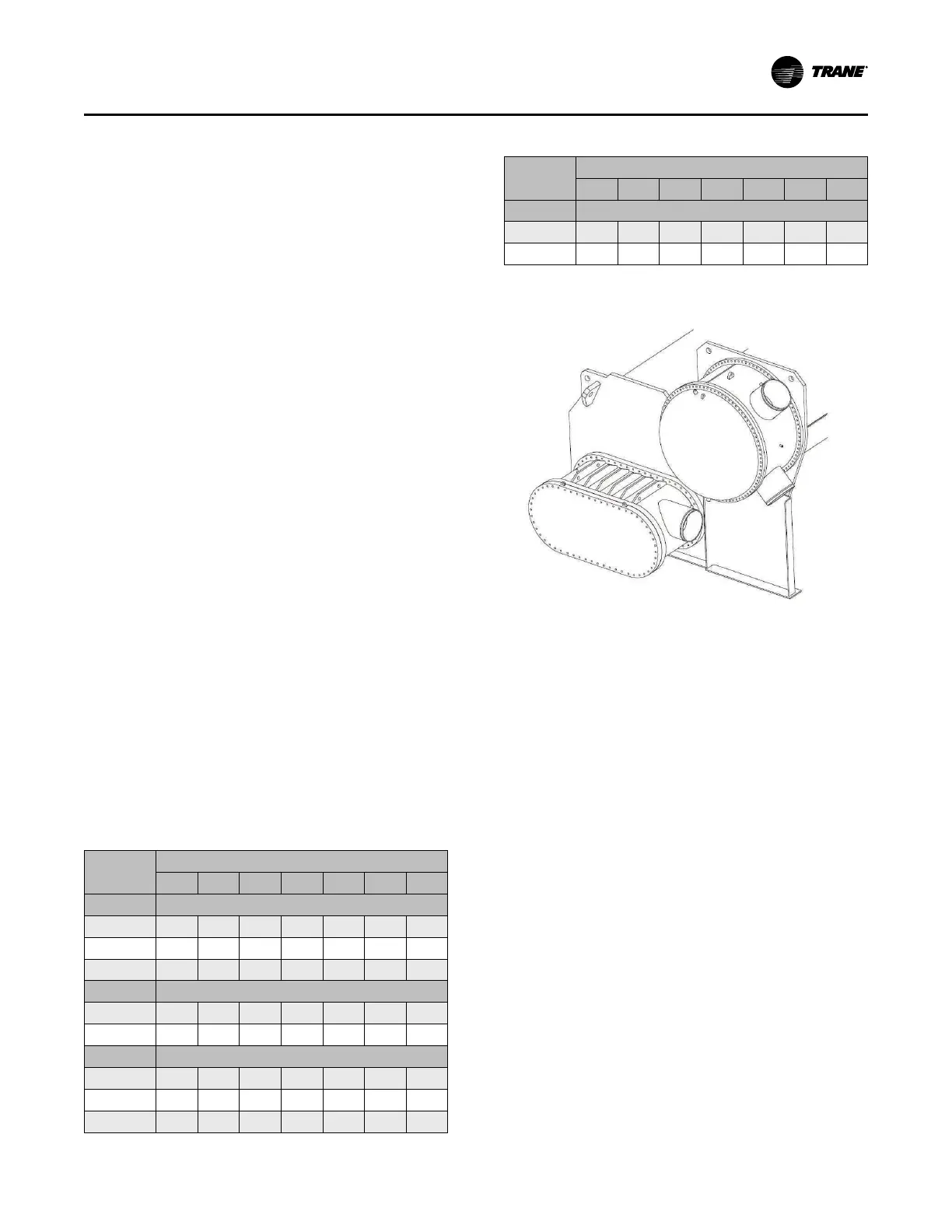

Figure 17. Typical grooved pipe connection

Waterbox Locations

If removal of waterboxes is necessary, refer to “Waterbox

Removal and Installation,” p. 111.

If the waterboxes on any of the shells are exchanged end-

for-end, be sure to reinstall them right-side up to maintain

the correct baffle arrangements. Use a new gasket with

each waterbox cover.

Three-pass waterboxes have lifting lugs on the top and

bottom. When reinstalling, ensure that the waterbox is

oriented the same way it as removed.

Grooved Pipe Coupling

A customer-supplied, standard flexible grooved pipe

coupling (Victaulic

®

Style 77 or equivalent) should be used

to complete the Victaulic

®

connection for both 150 psig

(1034.2 kPaG) and 300 psig (2068.4 kPaG) waterboxes.

When a flexible coupling such as this is installed at the

waterbox connections, other flexible piping connectors (i.e.,

braided-steel, elastomeric arch, etc.) are not usually

required to attenuate vibration and/or prevent stress on the

connections.

Installation: Water Piping

Loading...

Loading...