9

vacon • 116 Safe Torque Off

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

9.5 Connections

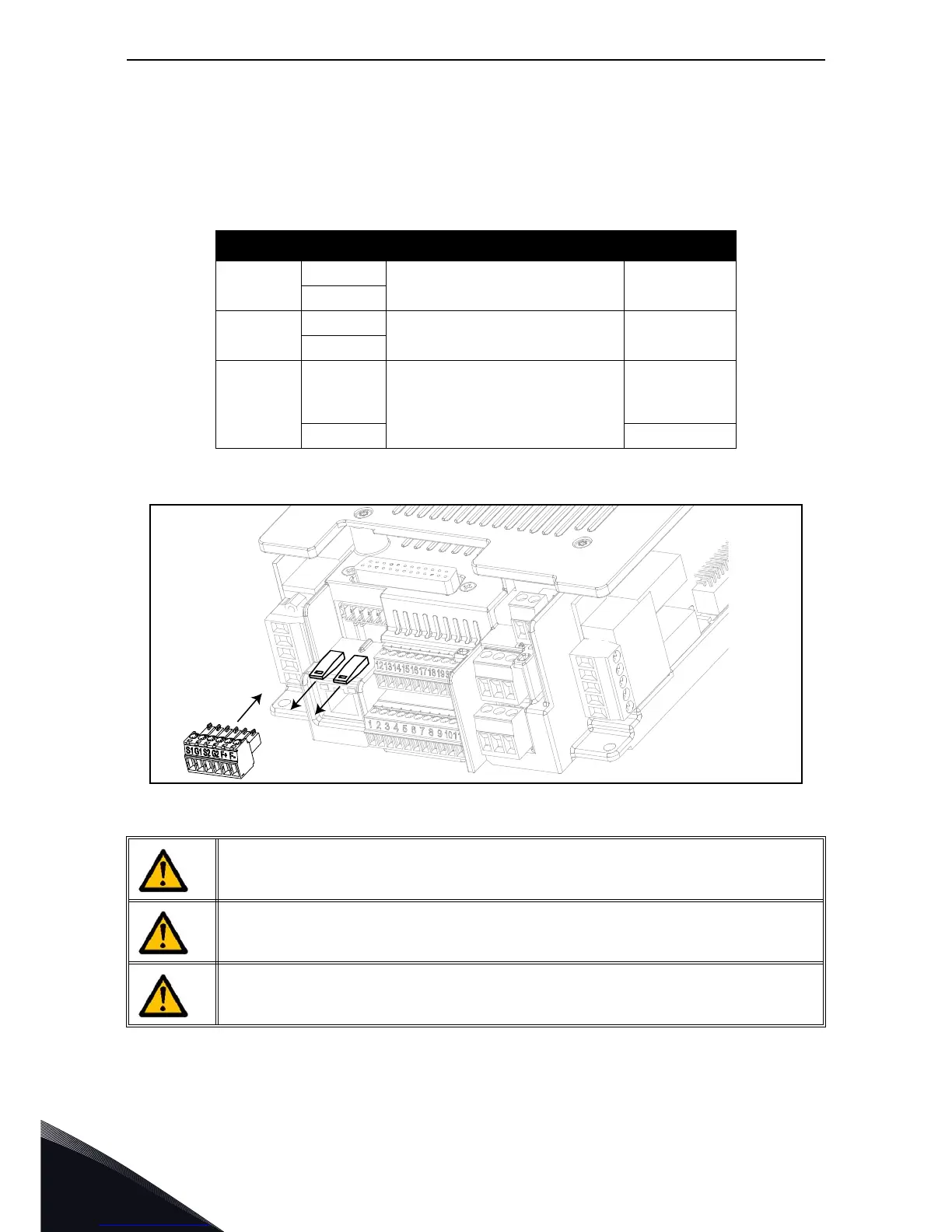

To make the STO function available and ready to be used, both the STO jumpers have to be removed.

They are located in front of the STO inputs to mechanically prevent the insertion of the STO connec-

tor. For the correct configuration, see the following table and the Figure 91.

Figure 91. Removing the STO jumpers.

The following examples show the basic principles for wiring the STO inputs and the STO output

feedback. Local standards and regulations must be always followed in the final design.

Table 47. STO connector and data signals.

Signal Terminal Technical information Data

STO1

S1

Insulated digital input 1

(interchangeable polarity)

24V ±20%

10...15 mA

G1

STO2

S2

Insulated digital input 2

(interchangeable polarity)

24V ±20%

10...15 mA

G2

STO feed-

back

F+

Insulated digital output for STO

feedback

(CAUTION! Polarity must be

respected)

24V ±20%

15 mA max.

F- GND

Make sure that the AC drive is switched off before cabling.

Disconnect both the STO jumpers to allow the cabling of the terminals.

When the STO function is used, the IP-class of the drive may not be reduced below

IP54. The IP-class of drive is IP66. It can be reduced by the wrong use of the cable

entry plates or the cable glands.

Loading...

Loading...