shaft synchronization application – parameter lists vacon • 17

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

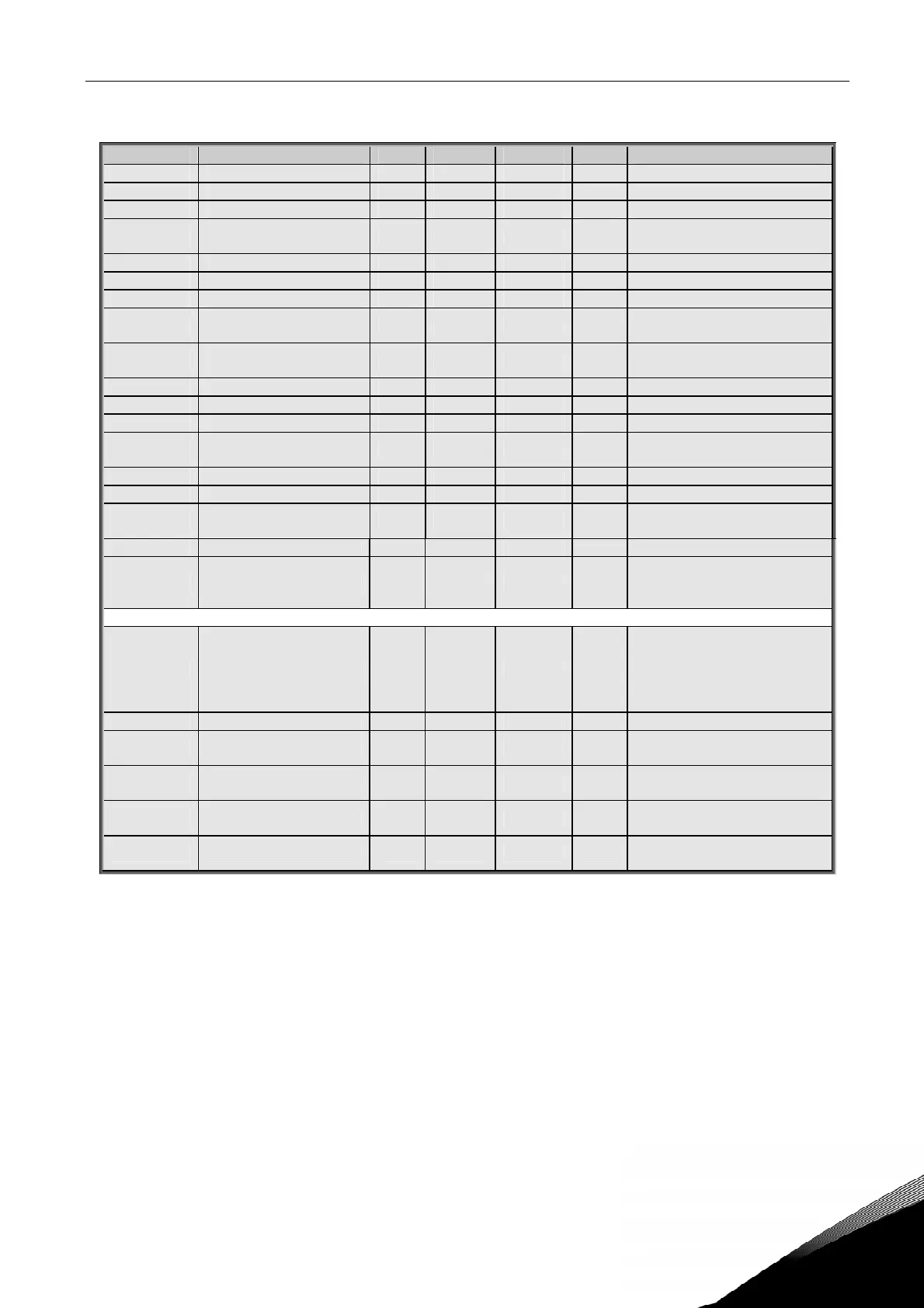

6.3.5 Digital inputs (Control keypad: Menu M2 G2.2.5)

Code Parameter Min Default Cust ID Note

P2.2.5.1 Start signal 1 0 A.1 403

P2.2.5.2 Start signal 2 0 A.2 404

P2.2.5.3 Run enable 0 0.2 407 Motor start enabled (cc)

P2.2.5.4 Reverse 0 0.1 412

Direction forward (oc)

Direction reverse (cc)

P2.2.5.5 Preset speed 1 0 0.1 419

P2.2.5.6 Preset speed 2 0 0.1 420

P2.2.5.7 Preset speed 3 0 0.1 421

P2.2.5.8

Motor potentiometer

reference DOWN

0 0.1 417

Mot.pot. reference decreases

(cc)

P2.2.5.9

Motor potentiometer

reference UP

0 0.1 418

Mot.pot. reference increases

(cc)

P2.2.5.10 Fault reset 0 0.1 414 All faults reset (cc)

P2.2.5.11 External fault (close) 0 0.1 405 Ext. fault displayed (cc)

P2.2.5.12 External fault (open) 0 0.2 406 Ext. fault displayed (oc)

P2.2.5.13 Acc/Dec time selection 0 0.1 408

Acc/Dec time 1 (oc)

Acc/Dec time 2 (cc)

P2.2.5.14 Acc/Dec prohibit 0 0.1 415 Acc/Dec prohibited (cc)

P2.2.5.15 DC braking 0 0.1 416 DC braking active (cc)

P2.2.5.16 Jogging speed 0 0.1 413

Jogging speed selected for

frequency reference (cc)

P2.2.5.17 AI1/AI2 selection 0 0.1 422

P2.2.5.18 Motor control mode 1/2 0 0.1 164

Closed cont.=Mode 2 is used

Open cont.=Mode 1 is used

See par 2.6.1, 2.6.12

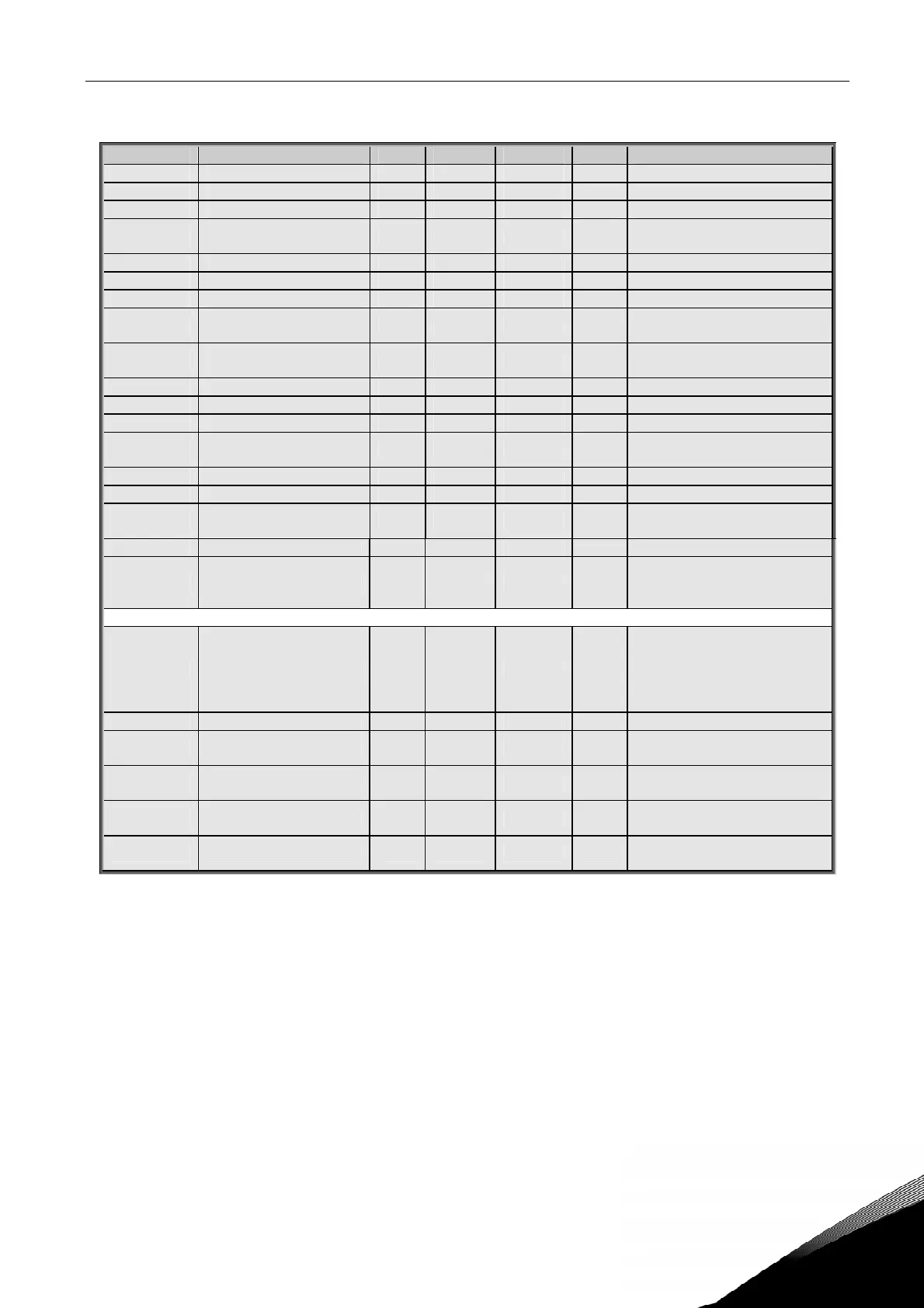

SHAFT SYNCHRONIZATION SPECIFIC PARAMETERS

P2.2.5.19 Synch. enable 0 A.3 1710

Enable shaft synchronization

control mode (software

license required)

Disabled = multi-purpose

control mode

P2.2.5.20 Synch. ModeBit0 0 A.4 1711 Engage synchronization input

P2.2.5.21 Synch. ModeBit1 0 A.5 1712

Reference speed/Freeze

follower speed request input

P2.2.5.22 Synch. trim + 0 0.1 1713

Trim input for increasing of

ratio in run mode

P2.2.5.23 Synch. trim - 0 0.1 1714

Trim input fordecreasing of

ratio in run mode

P2.2.5.24 Brake Opened Ack 0 0.1 1602

Hardware feedback from

mechanical brake.

Table 8. Digital input signals, G2.2.4

cc = closing contact

oc = opening contact

Loading...

Loading...