9.3.1 Calibration Setup

Using Hand-Held Meter as Reference

You can perform a 1-point calibration using a hand-held meter as a reference. You will need a

calibrated reference instrument to compare against, for example a GM70 hand-held meter

with a calibrated GMP222 probe.

With the probe and the reference instrument in the same space, allow the measurement to

stabilize before comparing the readings. Try to provide as stable an environment as you can

during this time. Avoid working around the probe and reference instrument during this time.

Using Calibration Gas as Reference

There are two easy ways to use a calibration gas as a reference:

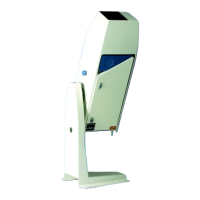

• You can supply the gas to the probe using the calibration adapter accessory (Vaisala

order code DRW244827SP). Gas

flow should be in the range 0.5 ... 1.1 l/min,

recommendation is 1 l/min. Allow the measurement to stabilize for three minutes before

starting the calibration.

• You can

fill the entire incubator with the calibration gas. You can use calibration gas a

reference by putting the probe in a suitable chamber (for example, an incubator) and

filling that chamber with the calibration gas.

To perform a two-point adjustment, you need two calibration gases: one gas that is below

1000 ppmCO

2

(low-end reference) and one that is above 2000 ppmCO

2

(high-end

reference).

When supplying the gas from a gas bottle, make sure the gas bottle has stabilized to room

temperature before starting.

9.3.2

Eect of Environmental Compensations

The probe has various environmental compensations that improve its CO

2

measurement

accuracy (see Environmental Compensation (page 15)). As the calibration and adjustment

environment may

dier from the actual measurement environment, you must make sure

that the compensation settings are properly set. Here are some key points to remember:

• Pressure and temperature compensations have a significant eect on accuracy. If you

are using setpoint values instead of the values from the built-in temperature sensor or

an integrated system, make sure to correct the setpoints so that they correspond to

your calibration situation. Consider switching temperature compensation to use the

internal sensor and/or integrated system when calibrating, and then switching back

when calibration and adjustment is done.

• The

eect of background gas compensations for humidity and oxygen may be

significant when using calibration gases, since these gases are often dry and oxygen-

free. For example, pure nitrogen gas is typically used as a convenient 0 ppm CO

2

reference. As it does not contain any oxygen or humidity, the compensations for them

must be set to zero.

• Remember to restore the normal compensation settings after completing calibration

and adjustment. If you are integrating the calibration functionality of the probe as part

of a control software, also implement proper handling of the environmental

compensations.

Chapter 9 – Maintenance

95

Loading...

Loading...