Rev. 8

1–15

TORQUE VALUES

Torque applied is for the size of the bolt shank not the wrench size. On smaller bolts

use a torque wrench calibrated in inch pounds, not foot pounds.

When tightening fasteners with self-locking nuts the chart values must be

modified. The friction drag torque must be determined and then added to the

standard torque from the table. Due to the friction of the locking device noticeable

torque is required just to turn the nut onto the threads and does nothing to actually

tighten the parts together and stretch the bolt (clamp load). This is called friction drag

(or prevailing) torque. Run the nut down to where it nearly contacts the washer or

bearing surface and check the friction drag torque required to turn the nut. (At least one

thread should protrude from the nut). Add the friction drag torque to the standard torque.

This sum is referred to as the final (or total) torque, which should register on the

indicator or setting for a snap-over type torque wrench.

The propeller manufacturer and the engine manufacturer have specific torque

requirements for their equipment. Consult the appropriate manual for that information.

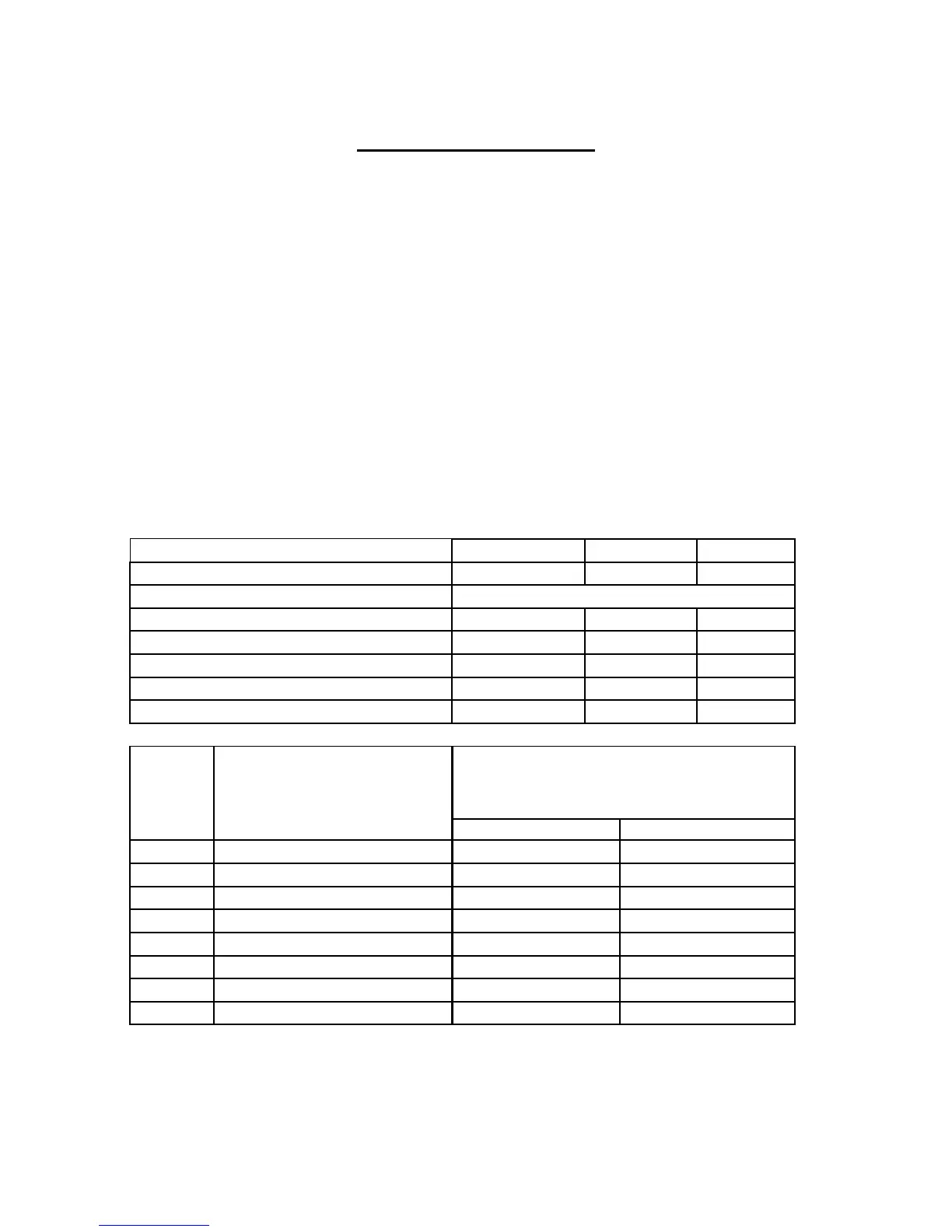

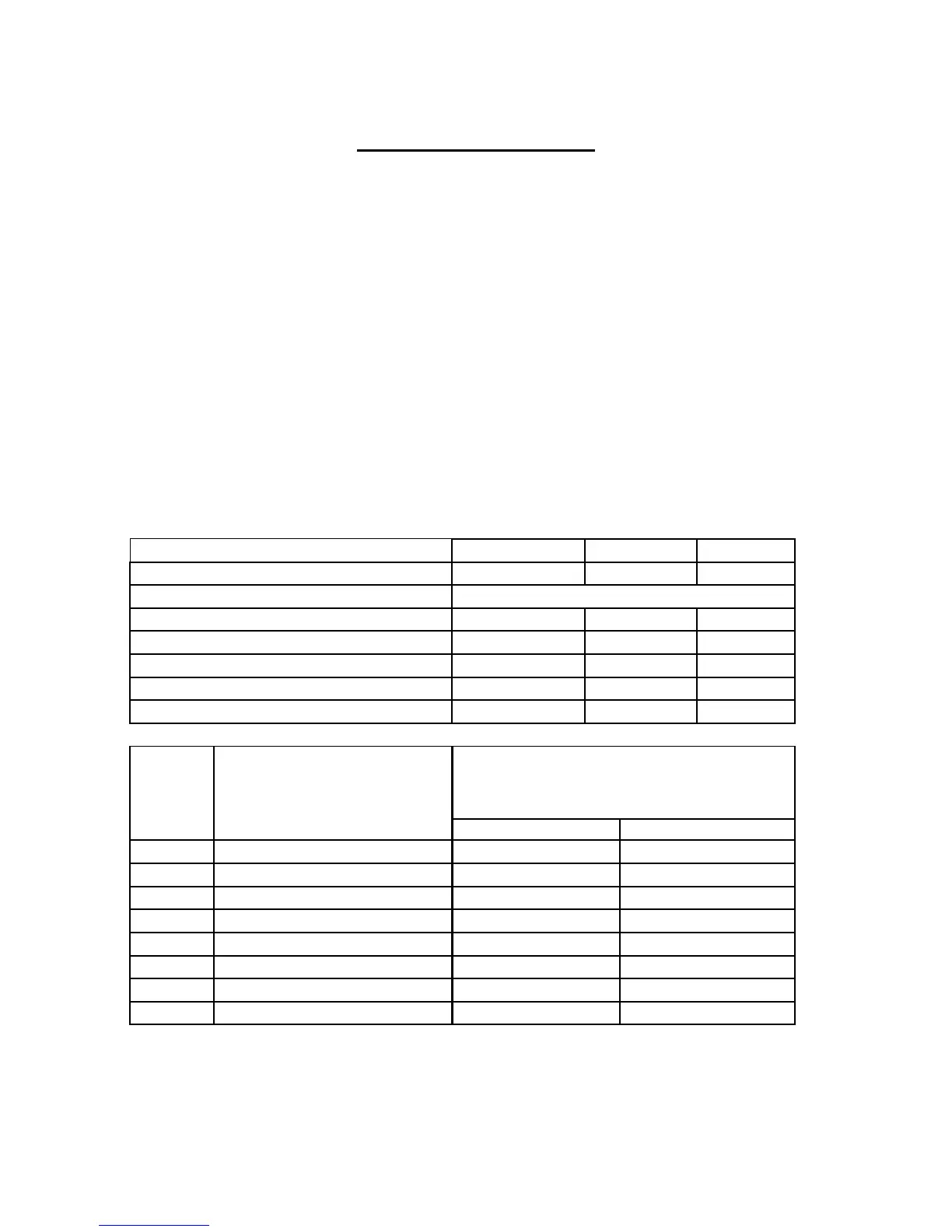

Contact + 3/4 Turn or as Specified

Bolt

size

Threads per inch

AN310, AN315,MS20365

(Portions of this information has been adapted from AC 43. 13)

Loading...

Loading...